- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2100**850*1800mm

-

Weight:

-

320 KG

-

Name:

-

capping machine

-

Model:

-

FX-200

-

Function:

-

Feed lid and capping

-

Bottle diameter:

-

35-140mm

-

Lid diameter:

-

15-60mm

-

Power:

-

1.5kw

-

Capping speed:

-

30-60 Bottles/Min

-

Air pressure:

-

0.4-0.6MPa

-

Customize service:

-

Yes

-

Marketing Type:

-

New Product 2021

Quick Details

-

Voltage:

-

220v/110v, 220v/110v 50/60hz

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FUSION

-

Dimension(L*W*H):

-

2100**850*1800mm

-

Weight:

-

320 KG

-

Name:

-

capping machine

-

Model:

-

FX-200

-

Function:

-

Feed lid and capping

-

Bottle diameter:

-

35-140mm

-

Lid diameter:

-

15-60mm

-

Power:

-

1.5kw

-

Capping speed:

-

30-60 Bottles/Min

-

Air pressure:

-

0.4-0.6MPa

-

Customize service:

-

Yes

-

Marketing Type:

-

New Product 2021

automatic linear capping machine with capping feeders Automatic bottle lid capper plastic trigger capping machine / 120ml chubby gorilla bottle filling capping machine auto filling cosmetic palm oil sauce production line automatic plastic cap with safety lock ring capping machine

1. Brief introduction of Capping machine

1,

2 parts CR cap assembly capping packing machine , full automatic

2,

Adopted 2 storage barrels matching vibratory disk to choice and arrange the cap direction.

3

, Automatic inspect caps whether lock completely after blockaged.

4,

End product unloading material treats and counting the quantity, the quantity may reset at will.

5,

Productivity speed according to the length of spiral tooth.

6,

Control system uses touche screen, the flow and the fault automatic demonstration, the operation is easy.

Cap category: medicine caps, salad oil, sunflower oil, edible oil and soft drink industries.

7,

Machine capacity: 30-60 pcs/min

8,

G/N Weight: 320/400 KGS.

2. Technical parameters :

|

Voltage |

AC 220V/60HZ 110V/50HZ |

|

Power |

1.5 kw |

|

Cap diameter |

φ15-φ60 mm |

|

Bottle diameter |

Φ35-φ140 mm |

|

Bottle height |

38mm-250 mm |

|

Capping speed |

30-60 pcs/min |

|

Air pressure |

0.4-0.6 Mpa |

|

Machine size |

2000*850*1800 mm |

|

Weight |

320 kg |

|

Note : Accept customized service according to your bottle and lid |

|

Suit for trigger caps, pump caps and sprayer caps.

1) widely used in many industry,such as,cosmetics,food,medicine etc

2) The machine can be suitable for sprayer caps, pump caps and trigger caps.

3) If you have trigger caps. Need to load the caps on the caps tracks one by one.

This Production Line is a whole Automatic paste filling production line solution;

The Machine Type, Number Of Machines, Speed, Capacity, Size, Etc. Of The Production Line Would Be Customized According To The

Customer'S Production Needs; We Can Develop A Professional Integrated Filling And Packaging Production Line Plan For The Customer.

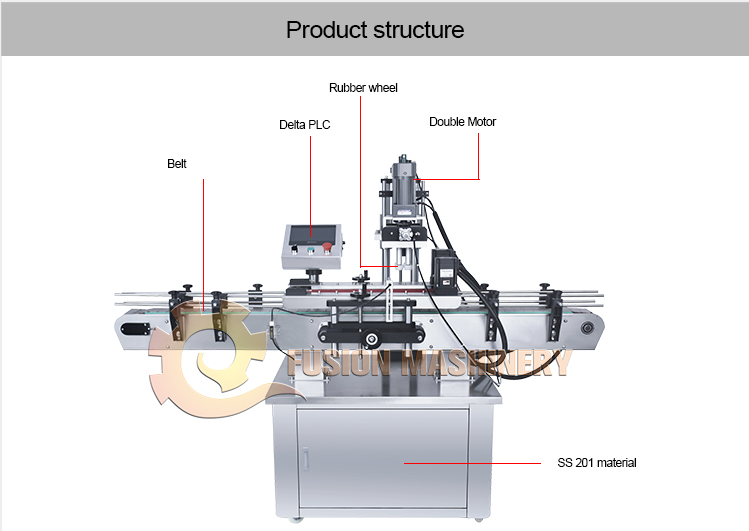

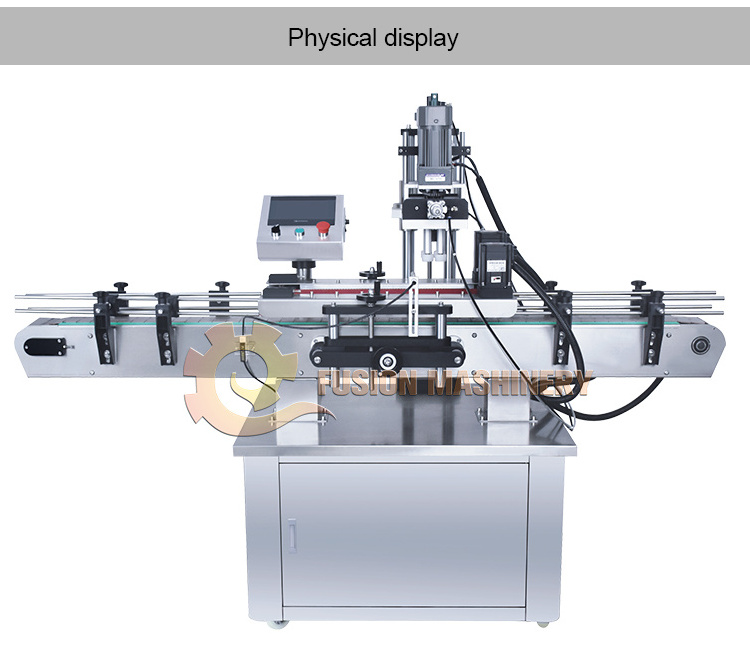

1. This machine is equipped with a Delta PLC touch screen device, fully automatic screw cap, suitable for all kinds of bottles, no liquid outflow.

2. The machine will accurately position each bottle.

3. Easy to operate, stable performance, widely used are features of this machine. It is widely used in pharmaceutical, chemical, food, beverage, light industry and other industries.

Function with - this machine comes with lid device management, anti-covered self-excluded;

Exchange specifications - Capping specifications change, simply adjust, easy to get.

Another type lids scew capping machine: (8 rounds capping machine)

1. Packing: PP film wrapped around the machine and carefully packed in wooden case to focus on protecting damageable parts.

2. Shipping: From port of Shenzhen, Shanghai, Qingdao, Guangzhou,etc. We also accept land, air, sea transport and international multimodal transport.

3. Clearance: Our long history makes us the one of the first and most knowledgeable providers of the equipment, our main customers hail from; Canada, the United States, Brazil, Argentina, Japan, Philippines, Australia, Russia, Thailand, the UAE, Poland, Spain, Germany, India, etc.

1. We always welcome customers to visit our manufacturing factory and get to know more about us.

2. Customers can see all the manufacturing workflows when they visit our factory. you can contact with online besides offline:

Tel/ Wechat/ WhatsAPP/ iMessages: +86 155 0374 7612

3. We also send engineers to the customer's place to help with the installation!

1.Ask:What is your guarantee of machine ?

Answer:Usually in our country is 220v,50hz, single phase , or 380v, 50hz, 3 phase .if you have the special requirement ,pls tell us, we will vetify the voltage according to your requirement.

Answer:we can intrust the install the machine by vedio, email ,picture.....if large project , we can arrange the worker help you to install it in your country .

Answer:

1. If you are interested in our products,please tell us which model,quantity you want to order

3. We will arrange the production and delivery when we received your payment

4. Payment terms:

30% as deposit,after seen the copy of the B/L sent by fax,the balance of 70% should be effected.

Fast and convenient, popular in the international trade!

---On-time shipment and pre-shipment product quality safeguards

---Refund up to the covered amount agree with your supplier

1. Sample order is available

2. OEM whole container

3. Mixed container order available