- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

RuiDa

-

Cutting Area:

-

1800x1200

-

Cutting Thickness:

-

0-6000mm

-

Control Software:

-

CNC CONTROL PROGRAM

-

Place of Origin:

-

Anhui, China

-

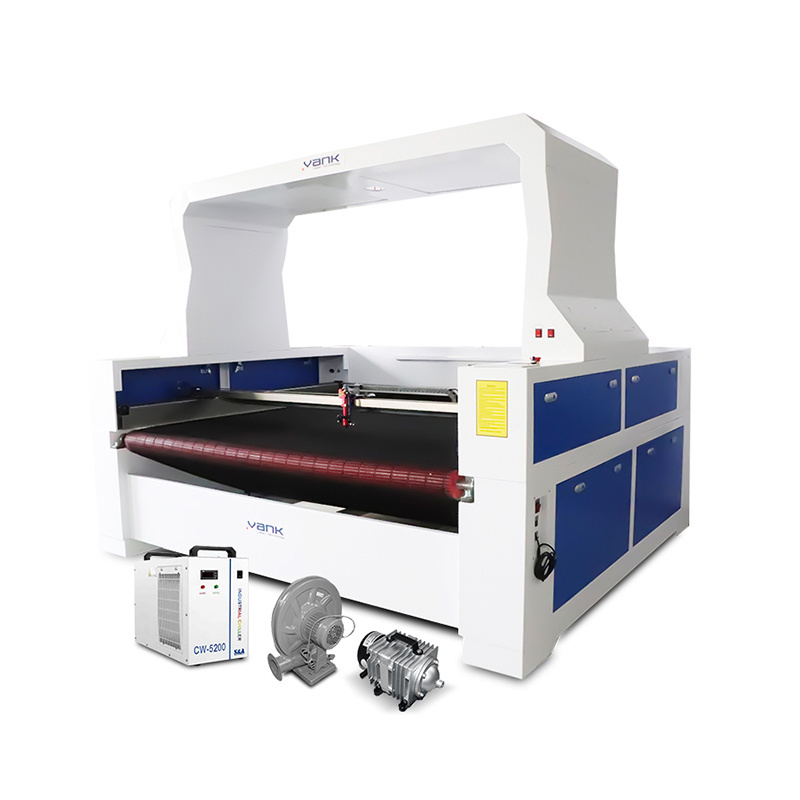

Brand Name:

-

VANK

-

Weight (KG):

-

600 KG

-

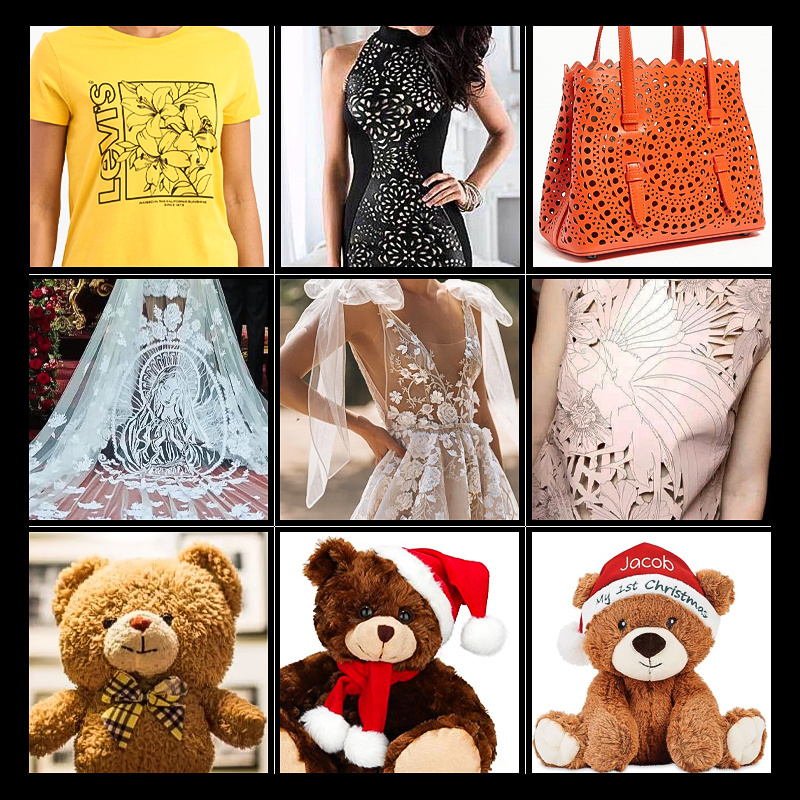

Products handled:

-

fabric

-

Application meterial:

-

Cloth,Fabric,leather

-

Product name:

-

C02 Laser Engraving Cutting Machine

-

Laser tube:

-

Sealed CO2 Glass Tube

-

Color:

-

White Black

-

Key words:

-

Leather Laser Machine

-

Working table:

-

Honeycomb Table

-

Power supply:

-

220V/50HZ 110V/60HZ

-

Cooling system:

-

Water Cooling System

-

Support Graphic Format:

-

PLT AI BMP DST DXF

-

Motor:

-

Leadshine Stepper

Quick Details

-

Laser Type:

-

CO2

-

Cutting Speed:

-

0-6000mm/s

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

RuiDa

-

Cutting Area:

-

1800x1200

-

Cutting Thickness:

-

0-6000mm

-

Control Software:

-

CNC CONTROL PROGRAM

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

VANK

-

Weight (KG):

-

600 KG

-

Products handled:

-

fabric

-

Application meterial:

-

Cloth,Fabric,leather

-

Product name:

-

C02 Laser Engraving Cutting Machine

-

Laser tube:

-

Sealed CO2 Glass Tube

-

Color:

-

White Black

-

Key words:

-

Leather Laser Machine

-

Working table:

-

Honeycomb Table

-

Power supply:

-

220V/50HZ 110V/60HZ

-

Cooling system:

-

Water Cooling System

-

Support Graphic Format:

-

PLT AI BMP DST DXF

-

Motor:

-

Leadshine Stepper

1)This laser cutting machine delivers fast and extremely accurate processing thanks to its high-quality components.Very dependable and maintenance free.

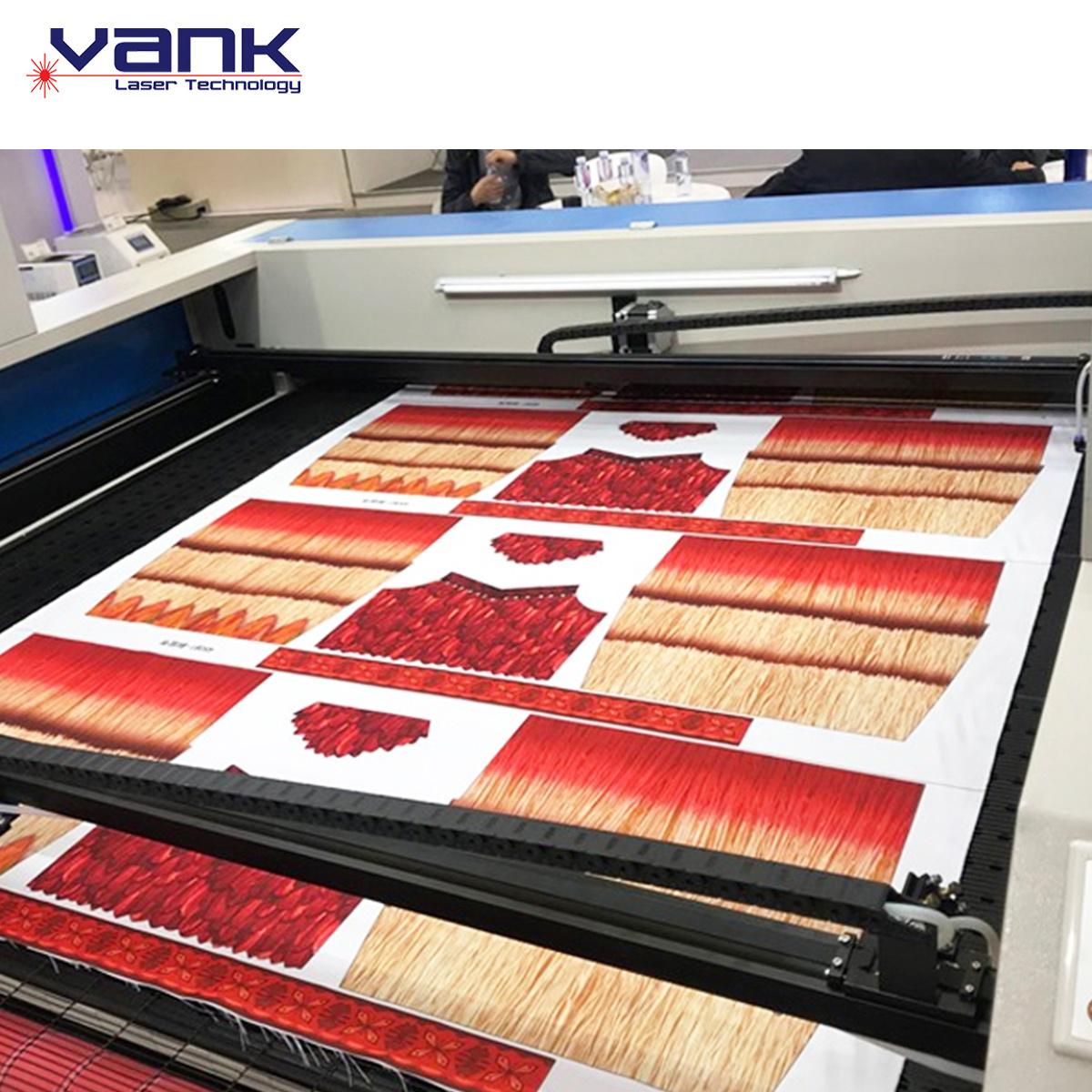

2)This laser machine comes with conveyor system. The machine feeds the material automatically in a continuous cycle in synchronism with the conveyor bed eliminating downtime completely to achieve the maximum productivity possible.

3)The vacuum conveyor worktable has the function of negative pressure adsorption to ensure the flatness of the fabric during laser cutting.

4)Automatic feeder with deviation correction function (optional) to ensure accurate feeding.

5)The unique manual and automatic interactive nesting software function can improve the fabric utilization to the extreme.

6)Along with the exhaust system, the laser head and the exhaust system synchronize; good exhaust effect, to ensure that dust dose not pollute the materials.

7)It is possible to complete entire format cutting of the extra-long layout with a single layout length that exceeds the cut format.

8)Along with the exhaust system, the laser head and the exhaust system synchronize; good exhaust effect, to ensure that dust dose not pollute the materials.

table after you put the rolls on the feeder. You can set the different feeding speeds according to the main machine speed. The

feeder has the sensor to ensure accurate positioning of the material.

The independent dual heads can cut different designs at the same time. It increases the cutting efficiency and production

flexibility at the largest degree.

|

MODEL

|

VANKPRO 1810/1812

|

|

|

|

|||

|

Laser Tube Power

|

80W/100W/120W/150W /300w

|

|

|

|

|||

|

Working Area

|

1800x1000mm/1800x1200

|

|

|

|

|||

|

Laser Tube

|

Sealed Glass Co2 Laser Tube,10.6um

|

|

|

|

|||

|

Cooling Type

|

Water Cooling

|

|

|

|

|||

|

Engraving Speed

|

0-60000mm/min

|

|

|

|

|||

|

Cutting Speed

|

0-40000mm/min

|

|

|

|

|||

|

Laser Output Control

|

0-100% set by software

|

|

|

|

|||

|

Min.Engraving Size

|

Chinese:2*2mm,English Letter:1*1mm

|

|

|

|

|||

|

Highest Scanning Precision

|

4000DPI

|

|

|

|

|||

|

Locating Accuracy

|

±0.01mm

|

|

|

|

|||

|

Control Software

|

Touch Panel Control

|

|

|

|

|||

|

Graphic Format Supported

|

DST/PLT/BMP/DXF/DWG/AI/HPGL...

|

|

|

|

|||

|

Compatible Software

|

CORELDRAW/PHOTOSHOP/AUTOCAD/TAJIMA....

|

|

|

|

|||

|

Drive System

|

High-precision 3-phase stepper motor

|

|

|

|

|||

|

Auxiliary Equipment

|

Exhaust fan and air exhaust pipe

|

|

|

|

|||

|

Power Supply

|

AC220V/220V+10% 50/6OHz

|

|

|

|

|||

|

Working Environment

|

Temperature:0-45°℃,Humidity 5-95%(No condensate water)

|

|

|

|

|||

And we are also offering the most competitive price to all of the customers."VANK" is known by more and more people.

1.

Q:Why should you choose us?

A:If you choose us, you will get best quality,best service,best price,best warranty.

2.Q:I'm not familiar with the machine.

A:You just need to tell us materials, working size and thickness.I will recommend you the right machine.

3:How to operate the machine

A:We will deliver English manual and video with the machine to you.If you still need our help,please contact us.

4.Q:How can I get the sample to check you quality ?

A:If you want to marking sample to check the quality, we can help you do this. first you need to provide the logo or design to us, free mark samples can be provided.

5.Q:Do the machine can be customized according my requirements?

A:Sure,we have a strong technical team and have rich experience. Our goal is to make you satisfied.

6.Q:Can you arrange the shipment for me?

A:We can arrange the shipment for our clients accordingly by sea and air. Trading terms FOB, CIF, EXW are available.