- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HAUAN

-

Voltage:

-

380V or as required

-

Dimension(L*W*H):

-

6000*500*1000mm

-

Weight:

-

3000 kg

-

Feeding width:

-

200-600mm

-

Marketing Type:

-

New Product

-

Product name:

-

aluminum metal door frame machine

-

Usage:

-

Steel Construction

-

Raw material:

-

PPGI PPGL GI GL

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Control system:

-

PLC(imported Brand)

-

Decoiler:

-

5T Manual Decoiler

-

Thickness:

-

0.3-0.8mm Thickness

-

Operate style:

-

Hydraulic Station Automatic Manual

-

Suitable to process:

-

Aluminum Zinc Coil

-

Advantage:

-

Easy Installation

Quick Details

-

Type:

-

door frame forming machine

-

Tile Type:

-

Steel/PPGI/PPGL/GI/GL

-

Production Capacity:

-

0-35m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HAUAN

-

Voltage:

-

380V or as required

-

Dimension(L*W*H):

-

6000*500*1000mm

-

Weight:

-

3000 kg

-

Feeding width:

-

200-600mm

-

Marketing Type:

-

New Product

-

Product name:

-

aluminum metal door frame machine

-

Usage:

-

Steel Construction

-

Raw material:

-

PPGI PPGL GI GL

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Control system:

-

PLC(imported Brand)

-

Decoiler:

-

5T Manual Decoiler

-

Thickness:

-

0.3-0.8mm Thickness

-

Operate style:

-

Hydraulic Station Automatic Manual

-

Suitable to process:

-

Aluminum Zinc Coil

-

Advantage:

-

Easy Installation

Products Description

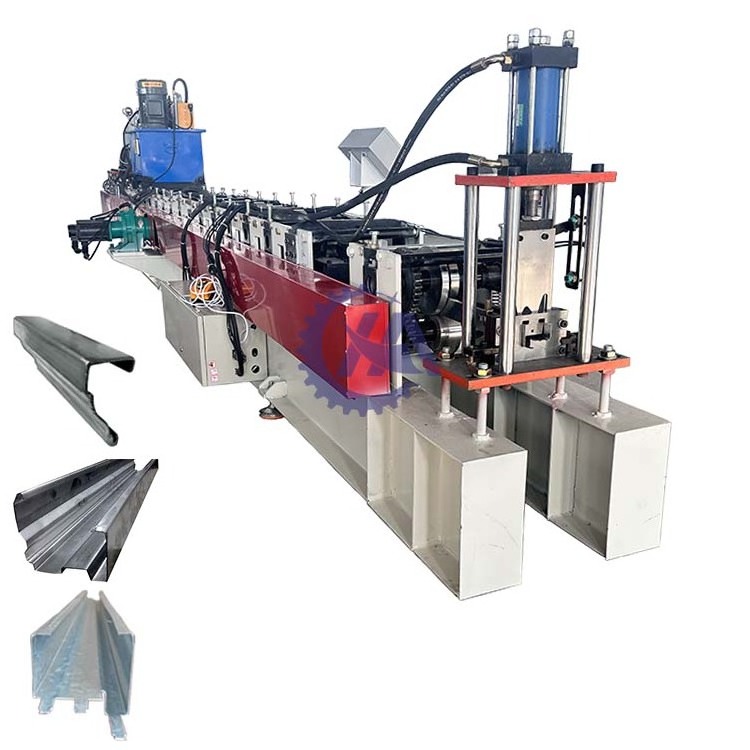

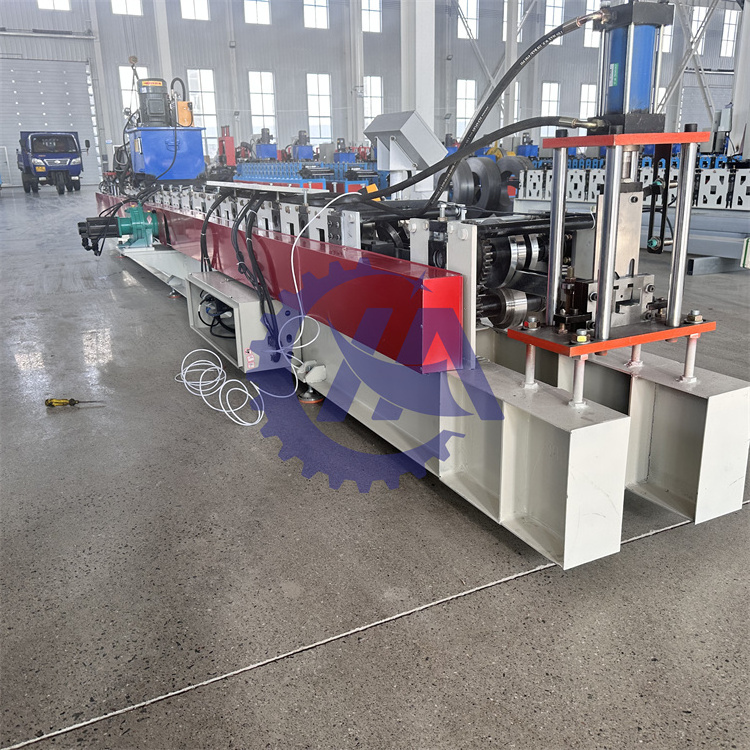

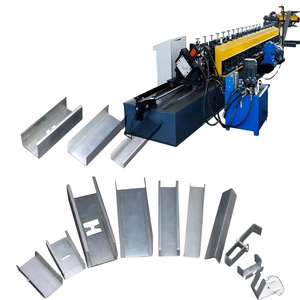

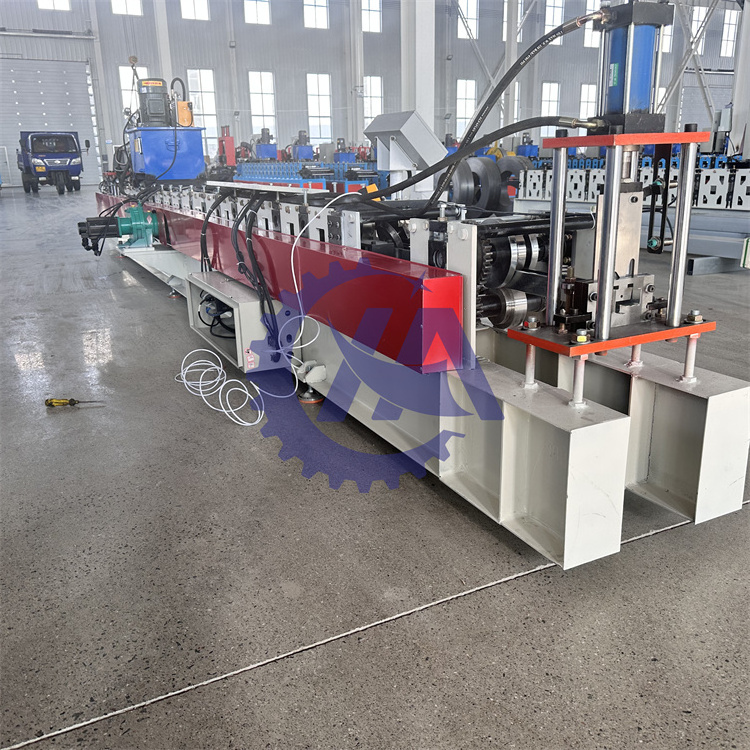

Hot sale metal steel aluminum door frame making bending machine

The door frame forming machine

is a device that adopts the principle of hydraulic transmission. Hydraulic oil is delivered to each oil cylinder through an oil pump, and the oil cylinder is driven to perform reciprocating motion, thereby realizing the forming of the door frame.

Work flow

:Automatic feeding - guiding - leveling, feeding - hydraulic punching - forming - lengthening, cutting - collecting

Product Paramenters

|

Item

|

Specification

|

|

Processing Material

|

Galvanized Steel/Color Coated Steel

|

|

Feeding Width

|

200-600mm

|

|

Effective Width

|

Customized

|

|

Material of Rollers

|

Gcr15

|

|

Diameter of Shaft

|

Ф70mm

|

|

Production Speed

|

10---20m/min

|

|

Roller Driven

|

Decelerating Motor+Chain Transmission

|

|

Cutting Model

|

Hydraulic Profile Cutting

|

|

Control Style

|

PLC control system(imported Brand)

|

|

Operation Model

|

Touch Screen or Buttom

|

|

Total Power

|

11KW

|

|

Voltage

|

380V 50HZ 3 phrases

|

|

Number of Roller Stations

|

12---16 rows

|

Product details

Hot sale metal steel aluminum door frame making bending machine

Leveling device

Its main function is to level the raw materials fed into the forming machine to ensure that the materials remain flat and wrinkle-free during the forming process, thereby improving the final product. quality and precision.

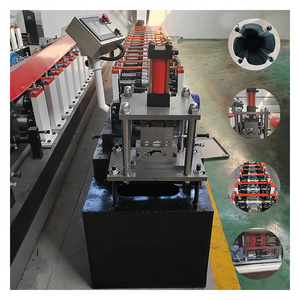

Roll Forming

Press & Punching

A press machine is any device that uses pressure to make or change metal materials. In other words,Punch presses use in hoses cutting, stamping, blanking.

Cutting off system

There are two different types of roll forming machines including a Pre-Cut roll forming machine. and Post Cut roll forming machine.

Text control system

Hot Searches