- Product Details

- {{item.text}}

Quick Details

-

Operating Pressure:

-

Ordinary Pressure

-

Raw Material:

-

Tires/Plastic/Rubber

-

Thickness Of Reactor:

-

14mm or 16mm

-

Mode Of Cooling:

-

Water Cooling

-

Cooling Area Of Condensers:

-

40 m3 or 65 m3

-

Weld:

-

Auto-Welding

-

Name:

-

Hot Sales Recapped Tires Pyrolysis/Refining/Distillation Machine

Quick Details

-

Place of Origin:

-

Henan, China

-

Material:

-

Q245R or Q345R Boiler Steel

-

Rotation Speed:

-

0.4 circle/minute

-

Operating Pressure:

-

Ordinary Pressure

-

Raw Material:

-

Tires/Plastic/Rubber

-

Thickness Of Reactor:

-

14mm or 16mm

-

Mode Of Cooling:

-

Water Cooling

-

Cooling Area Of Condensers:

-

40 m3 or 65 m3

-

Weld:

-

Auto-Welding

-

Name:

-

Hot Sales Recapped Tires Pyrolysis/Refining/Distillation Machine

Used tire pyrolysis recycling machine can turn waste tyre to fuel oil with latest pyrolysis technology. Pyrolysis is the thermal decomposition of materials in the absence of oxygen. In the case of the pyrolysis of rubber tyres, the rubber degrades under high temperatures and long-chain hydrocarbons in rubber are broken down into compounds with shorter carbon chains in the reactor, yielding oil, gas and carbon black.

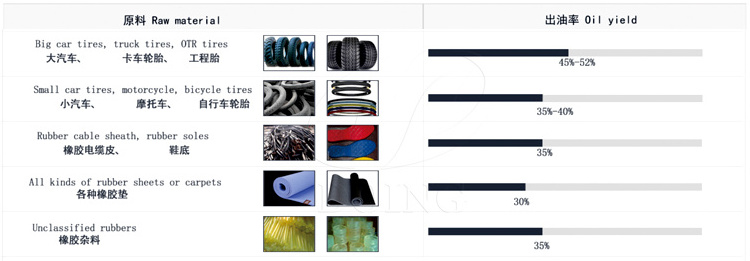

---The Raw Materials and Oil Yield of Different Input---

Our Used tire pyrolysis recycling machine can handle a variety of common tyres in life, and different tyres have different oil yield.

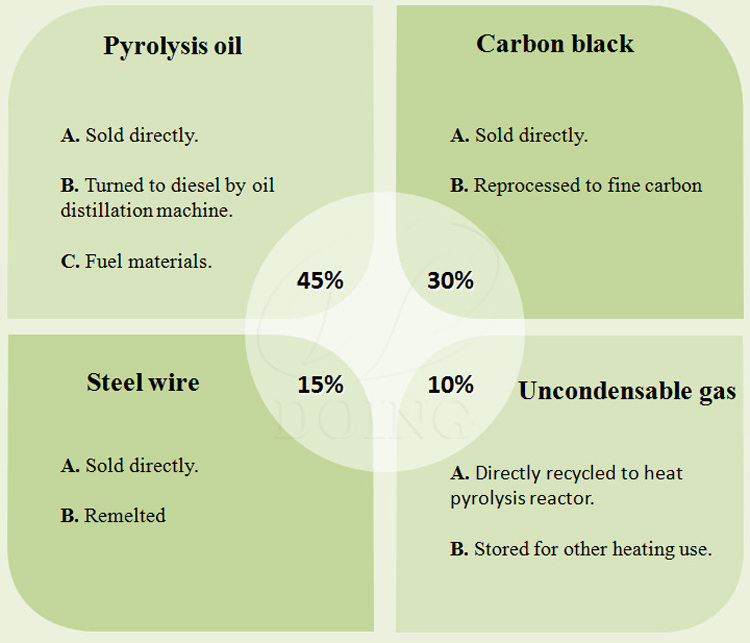

---The Product Application of Used tire pyrolysis recycling machine---

From Used tire pyrolysis recycling machine, 4 kinds of products can be obtained: fuel oil, catbon black, steel wire, and incondensable gas. Fuel oil is widely used in industries, such as steel factory, heavy oil generator, cement factory, and boiler heating etc. Carbon black can be made into pellets for making new rubber products. Steel wire could be sold to the recycle station or steel mill for remelting. The incondensable gas is recycled to heat the pyrolysis reactor, saving energy.

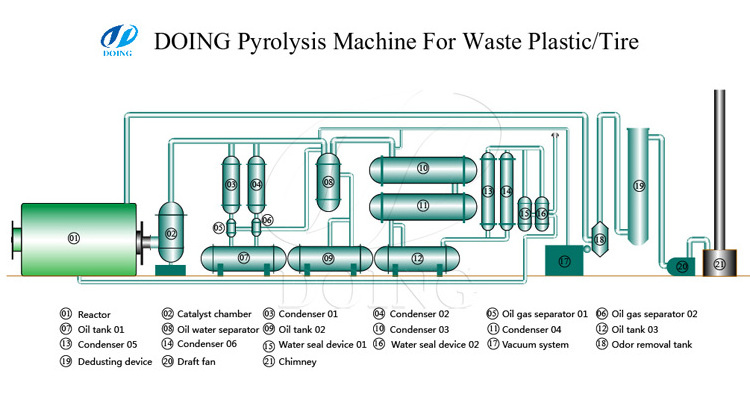

---The Main Working Process of Used tire pyrolysis recycling machine---

1. Put raw materials into reactor by auto-feeder, then heat the reactor. Do not stop heating the reactor, when the temperature reaches nearly 250 degree Celsius, waste tyre will be transferred to oil gas.

2.

The liquid oil will be cooled by condenser from oil gas and then collected by oil tank.

3.

The exhaust gas which can not be cooled in normal pressure will be recycled to heat the reactor. Smoke produced by processing the tyres can achieve national emission standard through dual desulfurization and dusting removal device.

4.

After you get oil, the temperature will be low, at this time, carbon black will be discharged automatically.

---Profit Analysis of Used tire pyrolysis recycling machine

---

---Profit Analysis of Used tire pyrolysis recycling machine

---

|

Profit analysis of DOING 10TPD Used tire pyrolysis recycling machine made by our Macedonia customer

|

||

| Cost for one batch | ||

| NO. | Item | Cost of each batch |

| 1. | 10tons of waste tire | 10T*USD42.5/T=USD425 |

| 2. | 0.4tons of coal | 0.4T*USD70/T=USD28 |

| 3. | Electricity and water | 244kwh*USD0.26=USD63.44 |

| 4. | Wokers | 4*USD15=USD60 |

| 5. | Total cost | USD576.44 |

| Income for one batch | ||

| 1. | Crude oil | 4.5T*USD960=USD4,320 |

| 2. | Steel wire | 10T*15%*USD350/T=USD525 |

| 3. | Carbon black | 3T*USD20/T=USD60 |

| Total income | USD4,905 | |

| Profit | ||

| 1. | Daily profit | USD4,328.56 |

| 2. | Month profit | 4328.56*25days=USD108,214 |

| 3. | Annual profit | USD108,214*10months=USD1,082,140 |

---The Main Advantages of Used tire pyrolysis recycling machine---

1. Safety

The Used tire pyrolysis recycling machine business is equipped with mature safety devices, such as alarm for over temperature and pressure, auto pressure releasing system, extra gas recycling system and fire fighting device, which will guarantee 100% safety in the tyre to oil recycling process.

2. Energy-saving

By the extra gas recycling system, the gas that can not be condensed will be recycled to the burning room. It can replace the fuel material to heat the reactor, which will reduce additional fuel consumption.

3. Environment friendly

In the dedusting system, three steps (water spray, ceramic ring filter, washing chamber) are used to dedust the extra gas and more than 95% of the dust would be removed. The released gas is pollution-free and can be discharged into the air directly with ISO9001:2008,CE Certificate.

4.Strict requirements for quality

IQC:Incoming quality control,main raw material;

PQC:Process quality control,All the reactor is inspection by X-ray.

---Packagine&Shipping of Used tire pyrolysis recycling machine---

---Project Case of Used tire pyrolysis recycling machine ---

By now we have installed hundreds of Used tire pyrolysis recycling machine in about 60 countries:

Africa: Nigeria, Congo, Egypt, Uganda;

Europe: Romania, Poland, Italy, Macedonia, Albania, Turkey;

Asia: Malaysia, Pakistan, India, Thailand, Iran, Bangladesh, Lebanon, Jordan;

America: Mexico, Ecuador, Haiti, Guatamala, Aruba, Panama, Jamaica, etc.

Below is the picture of the installation in some countries.

Our Used tire pyrolysis recycling machine are welcomed by quite a few customers from home and abroad, here are some of the feedbacks:

---After-sales service of Used tire pyrolysis recycling machine ---

1. Delivery time - It will be 10-15 days after we receive the deposit.

2. Warranty -The warranty period for reactor and other parts except spare parts is 1 year.

The problem caused by wrong operation of workers shall not be responsible by our company.

3. Installation and Training

-Our company will send one technician for each set of machine for guiding your installation, testing the machine and training your worker.