- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

220V/380V

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

building tomato processing or distribution line

-

Name:

-

SH-JUMP turnkey tomato processing project

-

Feature:

-

turnkey solution,from A to Z service

-

Capacity:

-

reasonal design for customer,1T/H to 100T/H

-

Material:

-

SUS304 Stainless Steel

-

Function:

-

Multifunctional

-

Usage:

-

Food Processing Industries

-

Item:

-

Automatic Fruits Juicer Machine

-

Color:

-

Customers' Requirements

-

Applicable Industries:

-

Manufacturing Plant, Food & Beverage Factory

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Showroom Location:

-

None

-

Video outgoing-inspection:

-

Provided

-

Machinery Test Report:

-

Provided

-

Marketing Type:

-

Ordinary Product

-

Warranty of core components:

-

1 Year

-

Core Components:

-

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

-

Condition:

-

New

-

Warranty:

-

1 Year warranty,life-long aftersell service

-

Certification:

-

CE/ISO9001

-

Power:

-

depends on whole line capacity

Quick Details

-

Brand Name:

-

SHJUMP

-

Dimension(L*W*H):

-

depends on whole line capacity

-

Weight:

-

200 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

220V/380V

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

building tomato processing or distribution line

-

Name:

-

SH-JUMP turnkey tomato processing project

-

Feature:

-

turnkey solution,from A to Z service

-

Capacity:

-

reasonal design for customer,1T/H to 100T/H

-

Material:

-

SUS304 Stainless Steel

-

Function:

-

Multifunctional

-

Usage:

-

Food Processing Industries

-

Item:

-

Automatic Fruits Juicer Machine

-

Color:

-

Customers' Requirements

-

Applicable Industries:

-

Manufacturing Plant, Food & Beverage Factory

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Showroom Location:

-

None

-

Video outgoing-inspection:

-

Provided

-

Machinery Test Report:

-

Provided

-

Marketing Type:

-

Ordinary Product

-

Warranty of core components:

-

1 Year

-

Core Components:

-

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

-

Condition:

-

New

-

Warranty:

-

1 Year warranty,life-long aftersell service

-

Certification:

-

CE/ISO9001

-

Power:

-

depends on whole line capacity

Bucket Elevator

1. smooth bucket structure against clamping fruits, suitable for tomato, strawberry, apple, pear, apricot, etc.

2. running stably with low noise, speed adjustable by transducer.

3. anticorrosive bearings, double sides seal.

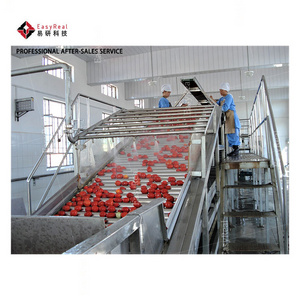

Air Blowing & Washing Machine

1 Used to wash fresh tomato, strawberry, mango, etc.

2 Special design of surfing and bubbling to ensure a through cleaning and lessening the damage to the fruit as well.

3 Suitable for many kinds of fruit or vegetables, such as tomatoes, strawberry, apple,mango,etc.

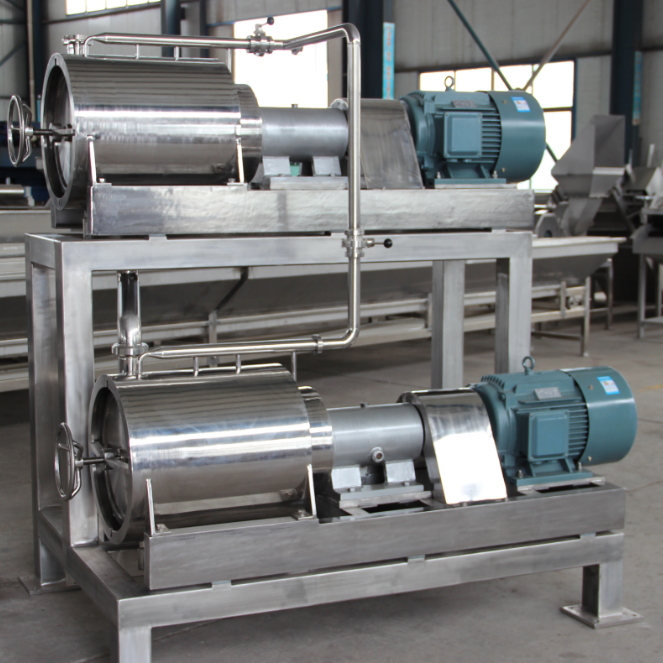

Peeling, pulping & Refining Monobloc (Pulper)

1. The unit can peel, pulp and refine fruits together.

2. The aperture of strainer screen can be adjustable (change) based on customer’s requirement.

3. Incorporated Italian technology, high quality stainless steel material in contact with fruit material.

Belt press extractor

1. Widely used in extracting and dehydrating of many kinds of acinus, pip fruits, and vegetables.

2. the unit adopt advanced technology, big press and high efficiency, high degree of automatic, easy to operate and maintains.

3. the extraction rate can be get 75-85%(based on raw material)

4. low investment and high efficiency

Preheater

1. To inactivate enzyme and protect color of paste.

2. Auto temperature control and the out temperature are adjustable.

3. Multi-tubular structure with end cover

4. If the effect of preheat and extinguish enzyme failed or not enough, the product flow return to tube again automatically.

Evaporator

1. Adjustable and controllable direct contact heat treatment units.

2. Shortest possible residence time, presence of a thin film along the entire length of the tubes reduces holdup and residence time.

3. Special design of liquid distribution systems to ensure correct tube coverage. The feed enters at the top of the calandria where a distributor ensures film formation on the inside surface of each tube.

4. The vapor flow is co-current to the liquid and the vapor drag improves the heat transfer. The vapor and the remaining liquid are separated in a cyclone separator.

5. Efficient design of separators.

6. Multiple effect arrangement provides steam economy.

Tube in tube sterilizer

1. The united is consisted of product receiving tank, superheated water tank, pumps, product dual filter, tubular superheated water generate system, tube in tube heat exchanger, PLC control system, Control cabinet, steam inlet system, valves and sensors, etc.

2. Incorporated Italian technology and conform to Euro-standard

3. Great heat exchange area, low energy consumption and easy maintenance

4. Adopt mirror welding tech and keep the smooth pipe joint

5. Auto backtrack if not enough sterilization

6. CIP and auto SIP available together with aseptic filler

7. Liquid level and temp controlled on real time

Process flow to make high-quality tomato paste:

1)

Receiving:

Fresh tomatoes arrive at the plant in trucks, which are directed to the offloading area. An operator, using a special tube or boom, pipes a vast quantity of water into the truck, so that the tomatoes can flow out from the special opening at the rear of the trailer. Using water allows the tomatoes move into the collection channel without being damaged.

2)

Sorting:

More water is continuously pumped into the collection channel. This water carries the tomatoes into the roller elevator, rinses them, and conveys them to the sorting station. At the sorting station, staff remove material other than tomatoes (MOT), as well as the green, damaged and discolored tomatoes. These are placed on a reject conveyor and then collected in a storage unit to be taken away. In some facilities, the sorting process is automated

3)

Chopping:

The tomatoes suitable for processing are pumped to the chopping station where they are chopped.

4)

Cold or Hot Break:

The pulp is pre-heated to 65-75°C for Cold Break processing or to 85-95°C for Hot Break processing.

5)

Juice Extraction:

The pulp (consisting of fiber, juice, skin and seeds) is then pumped through an extraction unit composed of a pulper and a refiner - these are essentially large sieves. Based on customer requirements, these mesh screens will allow more or less solid material to pass through, to make a coarser or smoother product, respectively.

Typically, 95% of the pulp makes it through both screens. The remaining 5%, comprised of fiber, skin and seeds, considered waste and is transported out of the facility to be sold as cattle feed.

6)

Holding Tank:

At this point the refined juice is collected in a large holding tank, which constantly feeds the evaporator.

7)

Evaporation:

Evaporation is the most energy-intensive step of the whole process – this is where the water is extracted, and the juice that is still only 5% solid becomes 28% to 36% concentrated tomato paste. The evaporator automatically regulates juice intake and finished concentrate output; the operator only has to set the Brix value on the evaporator’s control panel to determine the level of concentration.

As the juice inside the evaporator passes through different stages, its concentration gradually increases until the required density is obtained in the final “finisher” stage. The entire concentration/evaporation process takes place under vacuum conditions, at temperatures significantly below 100°C.

8)

Aseptic Filling:

Most facilities package the finished product using aseptic bags, so that the product in the evaporator never comes into contact with air until it reaches the customer. The concentrate is sent from the evaporator directly to an aseptic tank – it is then pumped at high pressure through the aseptic sterilizer-cooler (also called a flash cooler) to the aseptic filler, where it is filled into large, pre-sterilized aseptic bags. Once packaged, the concentrate can be kept up to 24 months.

Some facilities choose to package their finished product under non-aseptic conditions. This paste must go through an additional step after packaging – it is heated to pasteurize the paste, and then kept under observation for 14 days before being released to the customer.

To design tomato processing line of energy and capital intensive. Just free free to contact

Company Introduction:

Shanghai JUMP Automatic Equipments Co., Ltd, is keeping leadership position in the tomato paste and concentrated apple juice processing line. We also have made brilliant achievements in other fruit& vegetable beverage equipments, such as:

1. Juice production line for orange juice, grape juice, jujube juice, coconut drink/coconut milk, pomegranate juice, watermelon juice, cranberry juice, peach juice, cantaloupe juice, papaya juice, sea buckthorn juice, orange juice, strawberry juice, mulberry juice, pineapple juice, kiwi juice, wolfberry juice, mango juice, sea buckthorn juice, exotic fruit juice, carrot juice, corn juice, guava juice, cranberry juice, blueberry juice, RRTJ, loquat juice and other juice drinks dilution filling production line

2. Can food production line for canned Peach, canned mushrooms, canned chili sauce, paste, canned arbutus, canned oranges, apples, canned pears, canned pineapple, canned green beans, canned bamboo shoots, canned cucumbers, canned carrots, canned tomato paste, canned cherries, canned cherry

3. Sauce production line for mango sauce, strawberry sauce, cranberry sauce, canned hawthorn sauce etc.

We grasped proficient technology and advanced biological enzyme technology, successfully applied in more than 120 domestic and foreign jam &juice production lines and we has helped client gain excellent products and good economic benefits.

Our unique-- Turnkey Solution. :

No need worry if you know little about how to carry out the plant in your country.We not only offer the equipments to you,but also provide one-stop service, from your warehouse designing (water, electricity ,steam) , worker training, machine installation and debugging, life-long after-sale service etc.

Consulting + Conception

As a first step and prior to project implementation, we will provide to you profoundly experienced and highly competent consulting services. Based on an extensive and thorough analysis of your actual situation and requirements we will develop your customized solution(s). In our understanding, customer-focused consultation means that all steps planned – from the initial conception phase to the final phase of implementation – will be conducted in a transparent and comprehensible manner.

Project Planning

A professional project planning approach is a prerequisite for the realization of complex automation projects. On the basis of each individual assignment we calculate time frames and resources, and define milestones and objectives. Due to our close contact and cooperation with you, in all project phases, this goal-oriented planning ensures the successful realization of your investment project.

Design + Engineering

Our specialists in the fields of mechatronics, control engineering, programming, and software development closely cooperate in the development phase. With the support of professional development tools , these jointly developed conceptions will then be translated into design and work plans.

Production + Assembly

In the production phase, our experienced engineers will implement our innovative ideas in turn-key plants. The close coordination between our project managers and our assembly teams ensures efficient and high-quality production results. After the successful completion of the test phase, the plant will be handed over to you.

Integration + Commissioning

In order to reduce any interference with associated production areas and processes to a minimum, and to guarantee a smooth set-up, the installation of your plant will be conducted by the engineers and service technicians who have been assigned to and accompanied the individual project development and production stages. Our experienced staff will ensure that all required interfaces work, and your plant will be successfully put into operation.

Select stainless steel bracket, food-grade and hard plastic or stainless steel scraper, smoothing blade architecture to prevent the fruit jam; Using imported anti-corrosion bearings, double-sided seal; with continuously variable transmission motor, variable frequency Speed and low operating costsTitle goes here.

Stainless steel roller conveyor, rotation and solution, a full range of check, no need ends. Manmade fruit platform, painted carbon steel bracket,stainless steel antiskid pedal,stainless steel fence.

C. Crusher

Fusing Italian technology, multiple sets of cross-blade structure, crusher size can be adjusted according to customer or specific project requirements, it will increase the juice juice rate of 2-3% relative to the traditional structure , which is suitable for production of onion sauce, carrot sauce, pepper sauce , apple sauce and other fruits and vegetables sauce and products

D. Double-stage pulping machine

It have tapered mesh structure and the gap with load can be adjusted, frequency control, so that the juice will be cleaner; Internal mesh aperture are based on customer or specific project requirements to order

E. Evaporator

Single-effect, double-effect,triple-effect and multi-effect evaporator, which will save more energy; Under vacuum, continuous low temperature cycle heating to maximize the protection of nutrients in the material as well as the originals. There are steam recovery system and double times condensate system, it can reduce the consumption of steam;

F. Sterilization machine

Having obtained nine patented technology, take full advantages of the material's own heat exchange to save energy-- about 40%

F. Filling machine

Adopt Italian technology, sub-head and double-headed, continuous filling, reduce return; Using steam injection to sterilize, to ensure filling in aseptic state , the shelf life of product will twp years at room temperature ; In the filling process,using turntable lifting mode to avoid secondary pollution.

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

We can suggest customer the most suitable machine according to their formula and Raw material. “Design and development”, “manufacturing”, “installation and commissioning”, “technical training” and “after sales service”. We can introduce you supplier of raw material, bottles, labels etc. Welcome you to our production workshop to learn how our engineer produce. We could customize machines according to your real need, and we could send our engineer to your factory to install machines and train your worker of Operation and maintenance. Any more requests. Just let us know.

After-sale service

1.Installation and commissioning: We will send experienced engineering and technical personnel to be responsible for the installation and commissioning of the equipment until the equipment is qualified to ensure that the equipment is in time and put into production;

2.Regular visits:To ensure the long-term stable operation of the equipment, we will be based on customer needs, provide one to three times a year to come to technical support and other integrated services;

3.Detailed inspection report: Whether the inspection regular service, or the annual maintenance, our engineers will provide a detailed inspection report for the customer and the company reference archive, in order to learn the equipment operation at any time;

4.Fully complete parts inventory: In order to reduce the cost of parts in your inventory, provide better and faster service, we prepared a complete inventory of parts of equipment, to meet customers possible period of want or need;

5.Professional and technical training:In order to ensure the performance of the customer's technical personnel to become familiar with the equipment, correctly grasp the equipment operation and maintenance procedures, in addition to install on-site technical training. Besides, you also can hold all kinds of professionals to the factory workshops, to help you faster and more comprehensive grasp of technology;

6.Software and consulting services:In order to allow your technical staff to have a greater understanding of the equipment related counseling, I will arrange to send the equipment regularly sent to the advisory and latest information magazine.No need worry if you know little about how to carry out the plant in your country.We not only offer the equipments to you,but also provide one-stop service, from your warehouse designing (water, electricity ,steam) , worker training, machine installation and debugging, life-long after-sale service etc.

Why choose us?

1."Quality is priority”. we always attach great importance to quality control from the very beginning to the very end;

2.we have a professional manufacture experience and machining equipment;

3.we are factory ,we can provide you the super quality and very competitive price;

4.company has a quality,young,innovative and strong scientific research technical team

Is your price competitive?

surely we will give you best factory price based on superior product and service.

Any warranty?

1.one year equipment warranty after successful installation & commissioning of equipment and maintenance for lifelong time;

2.free installation and test before sending and free training for operation

3.advice for the solutions best for customers requirements

How about the test running & installation?

1.Before delivery, we finish the test over 3 times.

2.If you take integral design, no need to installation at all. If parted design, we can send our technicians to your place if necessary.

How to choose your wanted type?

1.tell us your requirement of the productivity.

2.You know about our machines ,the just tell us the type.

3.Give us the detailed information about your raw material,Picture will be best