- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4200*850*1600mm

-

Power (kW):

-

7.5

-

Weight (KG):

-

1200 kg

-

Panel Feed Speed(m/min):

-

20m/min

-

Product name:

-

Wood Edge Binding Machine

-

Panel Thickness:

-

10~60mm

-

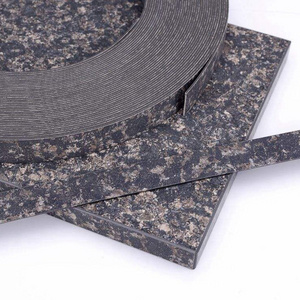

Edge Thickness:

-

0.4-3mm

-

Feeding speed:

-

12m/min

-

Application:

-

Kitchen Cabinet, Panel furniture,Wooden cabinet

-

Keywords:

-

Full-automatic Edge Banding Machine

-

Panel Width:

-

Min80mm

-

Air Pressure:

-

6kg/cm2

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BCAMCNC

-

Voltage:

-

380V/50HZ/3Phase

-

Dimension(L*W*H):

-

4200*850*1600mm

-

Power (kW):

-

7.5

-

Weight (KG):

-

1200 kg

-

Panel Feed Speed(m/min):

-

20m/min

-

Product name:

-

Wood Edge Binding Machine

-

Panel Thickness:

-

10~60mm

-

Edge Thickness:

-

0.4-3mm

-

Feeding speed:

-

12m/min

-

Application:

-

Kitchen Cabinet, Panel furniture,Wooden cabinet

-

Keywords:

-

Full-automatic Edge Banding Machine

-

Panel Width:

-

Min80mm

-

Air Pressure:

-

6kg/cm2

Product Description

Product advantages

1.The full automatic edge banding machine can polish the edge banding board , so that the color and smoothness of the edge banding board can be better

2.The full automatic edge banding machine can also scrape the ripple marks generated in the process of curve edge banding to ensure the smoothness of plate edge banding and surrounding parts .

3.The full automatic edge banding machine can apply glue on both side of the processed workpiece and edge banding strip through special setting and structure ,so as to make the adhesion between edge banding strip and plate more firm

1.The full automatic edge banding machine can polish the edge banding board , so that the color and smoothness of the edge banding board can be better

2.The full automatic edge banding machine can also scrape the ripple marks generated in the process of curve edge banding to ensure the smoothness of plate edge banding and surrounding parts .

3.The full automatic edge banding machine can apply glue on both side of the processed workpiece and edge banding strip through special setting and structure ,so as to make the adhesion between edge banding strip and plate more firm

|

Model

|

MF506 Edge Banding Machine

|

|

Panel Thickness

|

10~60mm

|

|

Edge Thickness

|

0.4-3mm

|

|

Panel Width

|

≥80mm

|

|

Band Thickness

|

0.3~3.0mm

|

|

Feed speed

|

12m/min

|

|

Motor power

|

7.5KW

|

|

Voltage

|

3.0kw water cooling spindle380V/50HZ/3Phase

|

|

Application

|

Kitchen Cabinet, Panel furniture,Wooden cabinet

|

Feature

1.special and advanced PUR gluing device with high quality and better gluing performance.

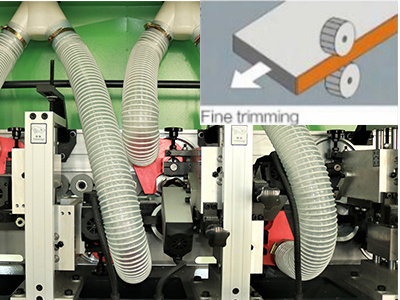

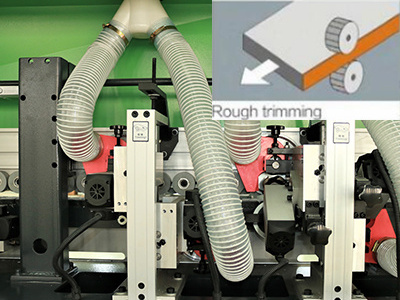

2.With functions Gluing ,End cutting ,Rough trimming Fine trimming ,Scraping ,Buffing .

3.With touch screen control panel ,making it more convenient and direct while running.

4.Any errors will displayed on the screen ,make it easier to repair .

5.The fine trimming unit with high speed motor, ensure the high quality trimming performance.

6.High Quality electrical components, make sure the stable performance.

1.special and advanced PUR gluing device with high quality and better gluing performance.

2.With functions Gluing ,End cutting ,Rough trimming Fine trimming ,Scraping ,Buffing .

3.With touch screen control panel ,making it more convenient and direct while running.

4.Any errors will displayed on the screen ,make it easier to repair .

5.The fine trimming unit with high speed motor, ensure the high quality trimming performance.

6.High Quality electrical components, make sure the stable performance.

product details

Delta touch screen

The machine is with 6 functions as follows gluing ,end trimming ,rough trimming fine trimming ,scraping,buffing .

And since it is physical scraping ,therefore there are five functions on the screen , so scraping function is not shown on the screen.

Gluing

Make the edge-banding board and the edge-banding material evenly coated on both sides to ensure stronger adhesion.

Make the edge-banding board and the edge-banding material evenly coated on both sides to ensure stronger adhesion.

End cut

Through the precise linear guide rail movement, the automatic tracking by the die and high frequency high-speed motor cutting

structure are adopted to ensure smooth and smooth cutting surface

Through the precise linear guide rail movement, the automatic tracking by the die and high frequency high-speed motor cutting

structure are adopted to ensure smooth and smooth cutting surface

Rough and fine trimming

The structure of automatic profiling and high-frequency high-speed motor is adopted to ensure the smoothness of the upper and

lower parts of the trimmed plate. It is used to repair and process the excess edge banding material above and below the edge band

of the plate.

The structure of automatic profiling and high-frequency high-speed motor is adopted to ensure the smoothness of the upper and

lower parts of the trimmed plate. It is used to repair and process the excess edge banding material above and below the edge band

of the plate.

Scraping

It is used to eliminate the ripple marks caused by the cutting process of the non-linear motion of the trimming, so that the upper and lower parts of the plate are smoother and cleaner

It is used to eliminate the ripple marks caused by the cutting process of the non-linear motion of the trimming, so that the upper and lower parts of the plate are smoother and cleaner

Buffing

Use a cotton polishing wheel to clean the processed plates, and polish the edge-sealing end surface smoother.

Use a cotton polishing wheel to clean the processed plates, and polish the edge-sealing end surface smoother.

Application industry

Packing & Delivery

How is the packing?

1).With Standard plywood case, its compressive strength and bearing quality is better.

2).The board area is bit, the soil structure is good, it is better in leakproofness and waterproof.

3).When importing, the plywood case is with fumigation-free, the procedure is simple.

2.How long is the delivery time?

For standard machine, it would be 7-10 working days;

For non-standard and customized machines according to client's specific requirements, it would be 15-30 working days.

1).With Standard plywood case, its compressive strength and bearing quality is better.

2).The board area is bit, the soil structure is good, it is better in leakproofness and waterproof.

3).When importing, the plywood case is with fumigation-free, the procedure is simple.

2.How long is the delivery time?

For standard machine, it would be 7-10 working days;

For non-standard and customized machines according to client's specific requirements, it would be 15-30 working days.

Customer praise

About us

Jinan BCAMCNC Machinery Co., Ltd

., established in 2002, specializing in CNC machinery with rich experience!The company has two factories: CNC Router and laser machine factories and plants.

BCAMCNC is comprehensive in the production, design, manufacturing, trade and service of CNC machine, and provide high quality and good efficienct CNC machines worldwide. With a strong staff team, "Brand BCAMCNC" gained success in woodworking engraving machine, advertising engraving machine, stone engraving machine, metal engraving machine, laser engraving machine and laser cutting industry equipment. The production facilities occupies China's forefront in development and expansion.

"BCAMCNC Products are widely used in the fields of advertising, furniture, jewelry pieces, gifts, packaging etc., materials of metal, wood, stone, leather etc."BCAMCNC"is wellknown not only in China, but also in Russia, Southeast Asia, Middle East, Africa, the Americas, India and other foreign countries.

BCAMCNC has already established branches in Shanghai , Dongguan, as well as foreign countries, such as Armenia , UK and Georgia. This year, BCAMCNC established long-term cooperative relationship with internationally renowned company, Shanghai Bcamtech CO.,LTD

. In addition, we have established long-term cooperative relations in the field of laser machines with BCMTECH to develop CNC solution .

BCAMCNC always adhere to the principle --- First class reputation, first-class service and excellent products.

BCAMCNC is comprehensive in the production, design, manufacturing, trade and service of CNC machine, and provide high quality and good efficienct CNC machines worldwide. With a strong staff team, "Brand BCAMCNC" gained success in woodworking engraving machine, advertising engraving machine, stone engraving machine, metal engraving machine, laser engraving machine and laser cutting industry equipment. The production facilities occupies China's forefront in development and expansion.

"BCAMCNC Products are widely used in the fields of advertising, furniture, jewelry pieces, gifts, packaging etc., materials of metal, wood, stone, leather etc."BCAMCNC"is wellknown not only in China, but also in Russia, Southeast Asia, Middle East, Africa, the Americas, India and other foreign countries.

BCAMCNC has already established branches in Shanghai , Dongguan, as well as foreign countries, such as Armenia , UK and Georgia. This year, BCAMCNC established long-term cooperative relationship with internationally renowned company, Shanghai Bcamtech CO.,LTD

. In addition, we have established long-term cooperative relations in the field of laser machines with BCMTECH to develop CNC solution .

BCAMCNC always adhere to the principle --- First class reputation, first-class service and excellent products.

By Global High-Tech CNC Equipment Supplier---BCAMCNC

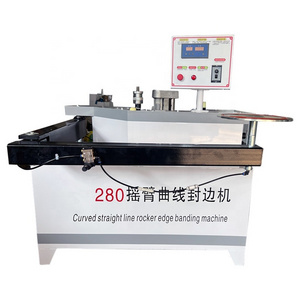

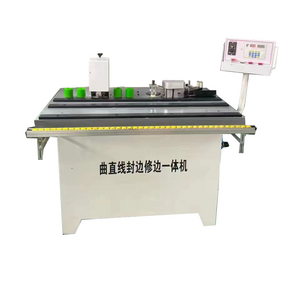

Related Products

FAQ

Q1: How do I get the best price?

A: Different type of CNC machine apply to the different price.

Q2: What machine suits me best?

A: Different material and the different model apply to the different machine.Please tell us what's material you want to cutting or engraving ?And what's MAX size of carved material ?We will recommend the most suitable model and the best price for you.

Q3: What should I do if the machine fails during warranty period?

A: Just contact us----our sales are online for 24-hours and ready to help.Replacement of damaged parts for free(make sure it is not broken because of wrong operation).The CD and operation manual----It shows the most common failures in working processing and how to solve the problems.

Q4: Are you trading company or manufacturer?

A: We are a factory direct sale, can guarantee you got the best product at the best price.All the products have CE, ISO

certifications, all the machines are tested well before delivery. There is a 12 months warranty.

Q5: How long is your delivery time?

A:Generally it is a weekday if the goods are in stock. or it is 15 working days if the goods are not in stock, it is according to

your quantity.

A: Different type of CNC machine apply to the different price.

Q2: What machine suits me best?

A: Different material and the different model apply to the different machine.Please tell us what's material you want to cutting or engraving ?And what's MAX size of carved material ?We will recommend the most suitable model and the best price for you.

Q3: What should I do if the machine fails during warranty period?

A: Just contact us----our sales are online for 24-hours and ready to help.Replacement of damaged parts for free(make sure it is not broken because of wrong operation).The CD and operation manual----It shows the most common failures in working processing and how to solve the problems.

Q4: Are you trading company or manufacturer?

A: We are a factory direct sale, can guarantee you got the best product at the best price.All the products have CE, ISO

certifications, all the machines are tested well before delivery. There is a 12 months warranty.

Q5: How long is your delivery time?

A:Generally it is a weekday if the goods are in stock. or it is 15 working days if the goods are not in stock, it is according to

your quantity.

Hot Searches