IPG/Raycus/MAX

All major brands of lasers are customized at will, and the pursuit of cost-effectiveness

10w+ hours of stable use

- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

3000*1500mm

-

Cutting Thickness:

-

0-30mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

China

-

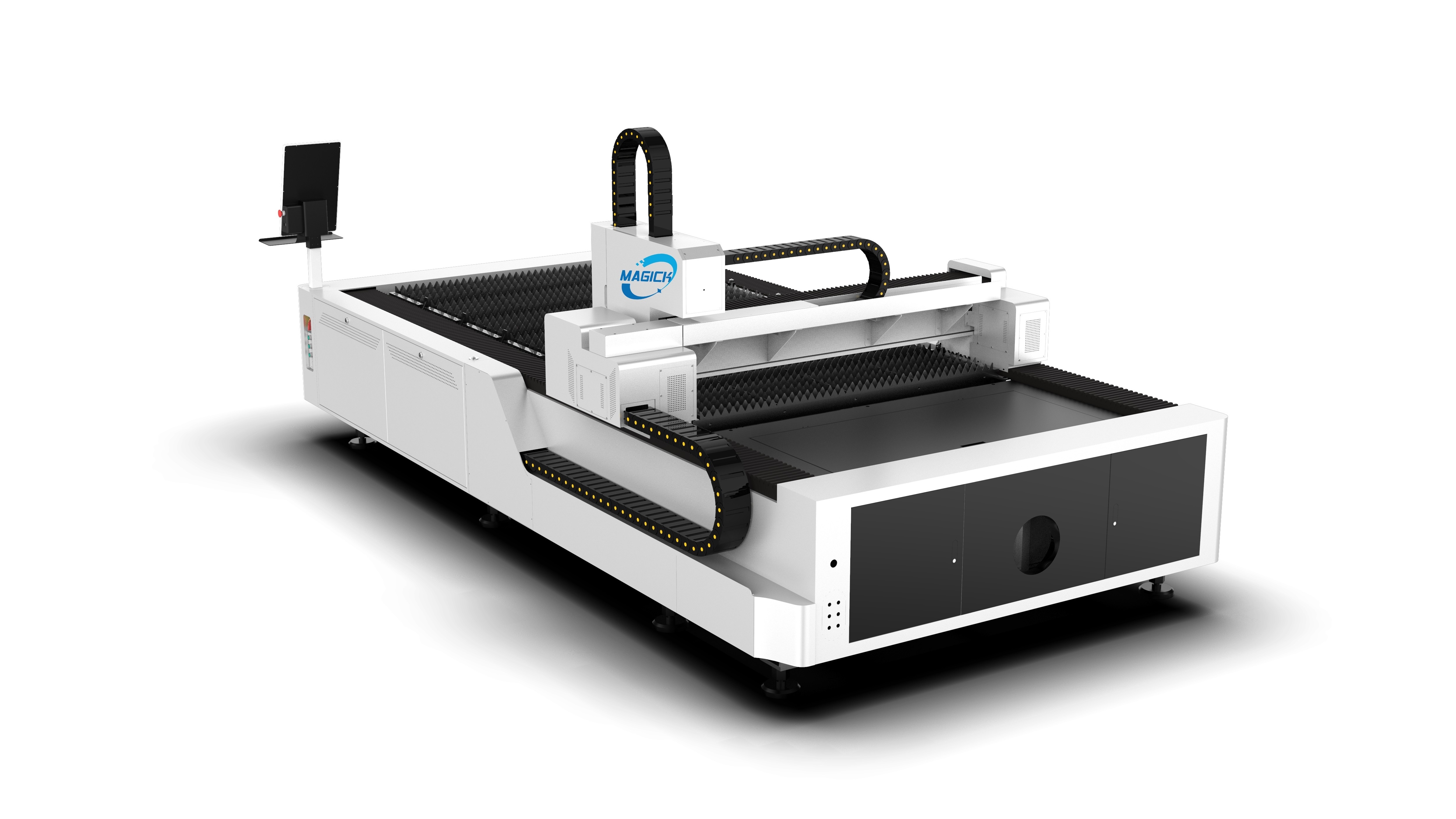

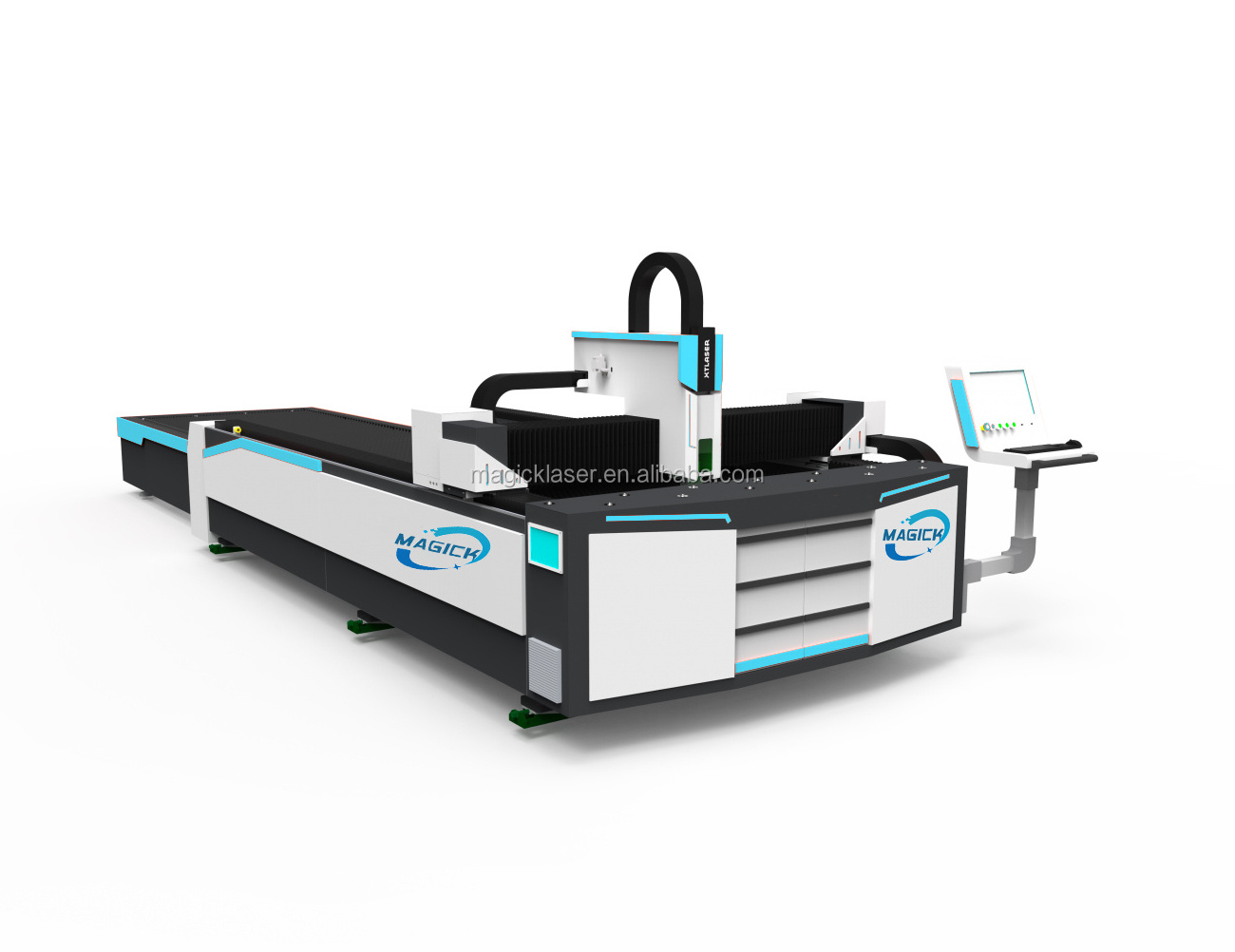

Brand Name:

-

magick

-

Weight (KG):

-

3500 KG

-

Keyword:

-

Fiber Laser Cutting Machiens

-

Laser power:

-

1000W / 2000W / 3000W/4000W

-

Cutting materials:

-

Stainless Steel Carbon Steel Etc( Metal Laser Cutting Machine )

-

Laser source:

-

MAX IPG RAYCUS

-

Laser head:

-

Switzerland Raytools

-

Control system:

-

Cypcut System

-

Working table:

-

Sawteeth Working Table

-

Power supply:

-

380V 50Hz/ 220V 60Hz

-

Driving system:

-

Driving system

-

Max cutting speed:

-

700mm/min

Quick Details

-

Laser Type:

-

Fiber Laser

-

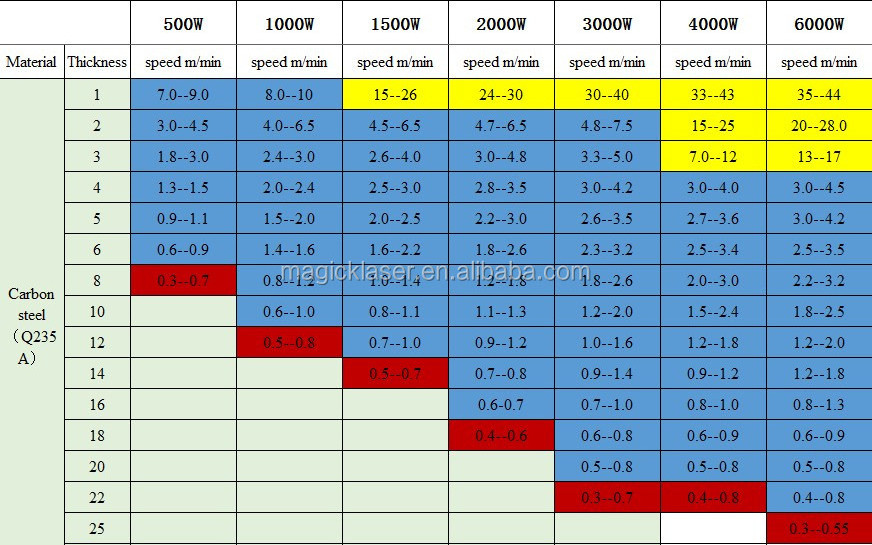

Cutting Speed:

-

120m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

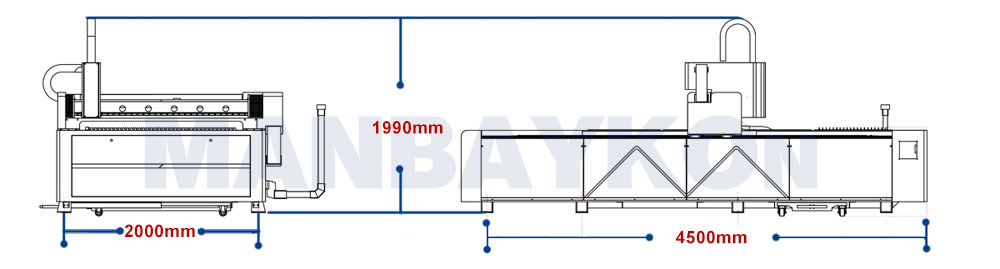

Cutting Area:

-

3000*1500mm

-

Cutting Thickness:

-

0-30mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

China

-

Brand Name:

-

magick

-

Weight (KG):

-

3500 KG

-

Keyword:

-

Fiber Laser Cutting Machiens

-

Laser power:

-

1000W / 2000W / 3000W/4000W

-

Cutting materials:

-

Stainless Steel Carbon Steel Etc( Metal Laser Cutting Machine )

-

Laser source:

-

MAX IPG RAYCUS

-

Laser head:

-

Switzerland Raytools

-

Control system:

-

Cypcut System

-

Working table:

-

Sawteeth Working Table

-

Power supply:

-

380V 50Hz/ 220V 60Hz

-

Driving system:

-

Driving system

-

Max cutting speed:

-

700mm/min

About cheap money making machines

Advantages of fiber laser cutting machine:

1. Excellent beam quality: the focusing light board is smaller, the cutting lines are finer, the work efficiency is higher, and

the processing quality is better.

the processing quality is better.

2. Fast cutting speed: The cutting speed is 2-3.5 times that of the same power CO2 laser cutting machine.

3. Stable operation: The world's top imported fiber lasers such as IPG/Raycus/MAX are used, with stable performance, and key components can reach 100,000 hours;

4. Very low maintenance cost: no laser working gas; optical fiber transmission, no need for reflective lenses; it can save a lot of maintenance costs.

5. Low cost: low power consumption, only about 20%-30% of thetraditional CO2 laser cutting machine, reducing production costs and making you profit faster.

6. Simple operation: optical fiberline transmission, no need to adjust the optical path, automatic focus without manual adjustment.

Main application industry:

Used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, machinery,precision parts, ships, metallurgical equipment, elevators, household appliances, gift crafts, tool processing, decorations,advertising, metal external processing, etc. Kind of manufacturing industry.

Mainly used for cutting low carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel plate,

pickling plate, aluminum zinc plate, copper and various metal materials.

pickling plate, aluminum zinc plate, copper and various metal materials.

|

item

|

value

|

|

Application

|

LASER CUTTING

|

|

Applicable Material

|

metal

|

|

Laser Type

|

Fiber Laser

|

|

Cutting Area

|

1500mm*3000mm/6000mm*2000mm/4000mm*2000mm

|

|

Graphic Format Supported

|

AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP

|

|

Cutting Thickness

|

0-30mm

|

|

Cooling Mode

|

WATER COOLING

|

|

Control Software

|

Cypcut

|

|

Place of Origin

|

China

|

|

Certification

|

ce

|

|

Laser Source Brand

|

MAX/Raycus/JPT/IPG

|

|

Laser Head Brand

|

Raytools

|

|

Servo Motor Brand

|

Yaskawa

|

|

Guiderail Brand

|

HIWIN

|

|

Control System Brand

|

Cypcut

|

|

Weight (KG)

|

2500KG

|

|

Key Selling Points

|

Competitive Price

|

|

Optical Lens Brand

|

Wavelength

|

|

Core Components

|

Laser source

|

Product details

01

Brand Laser

02

High-strength bed

High-strength sheet welding machine bed

600°C high temperature annealing for stress relief

No deformation after long time and high frequency use

600°C high temperature annealing for stress relief

No deformation after long time and high frequency use

03

Automatic focusing laser

Automatically adjust focus according to material thickness.

Multiple focal lengths, high-speed and accurate time saving

04

Design the best combination

Fuji/Yaskawa Electric +

EREFAT/modoli reducer

+

water cooling

+

Switezerland Raytools /Germany Precitec

EREFAT/modoli reducer

+

water cooling

+

Switezerland Raytools /Germany Precitec

05

Humanized operating system

Baichu 1000s/CYPONE/CYPCUT/ Weihong

Humanized customization to meet various needs

Humanized customization to meet various needs

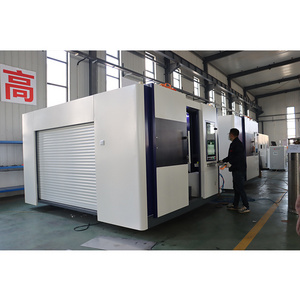

Production sample

Packing & Delivery

1.Standard wooden cases with sponge filled inside for packing protection

2. The Wooden case is fumigation free which is suitable by sea & by air.

3. Customized Packing as per Customer's requirement.

Hot Searches