- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1.36*1.60*0.85m

-

Weight:

-

350 kg

-

Marketing Type:

-

Hot Product 2023

-

Raw material:

-

Cereals, beans, fish meal, meat and bone meal

-

Final product:

-

Dog pet feed pellet

-

Usage:

-

Producing pet puffed food;floating fish feed puffed pellet machine

-

Spiral diameter:

-

40-160

-

Safety:

-

Protective equipment, emergency stop button

-

Certification:

-

CE

-

Advantage:

-

Easy operation and high efficiency

-

Automation degree:

-

Fully automatic

-

Color:

-

Clients requirement

Quick Details

-

Max. Capacity:

-

2 ton/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gondor

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1.36*1.60*0.85m

-

Weight:

-

350 kg

-

Marketing Type:

-

Hot Product 2023

-

Raw material:

-

Cereals, beans, fish meal, meat and bone meal

-

Final product:

-

Dog pet feed pellet

-

Usage:

-

Producing pet puffed food;floating fish feed puffed pellet machine

-

Spiral diameter:

-

40-160

-

Safety:

-

Protective equipment, emergency stop button

-

Certification:

-

CE

-

Advantage:

-

Easy operation and high efficiency

-

Automation degree:

-

Fully automatic

-

Color:

-

Clients requirement

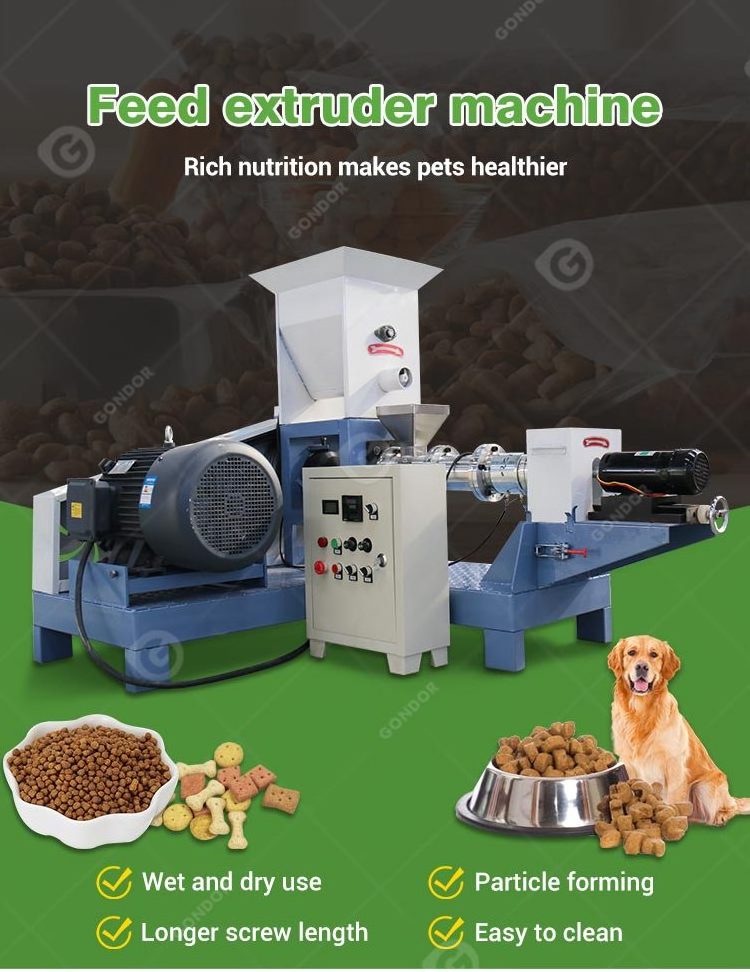

Introduction

Feed extruder machine is feed extrusion equipment. A variety of shapes can be produced, and molds can be customized according to requirements. The product outlet is equipped with a variable frequency rotary cutting device, which can adjust the blade rotation speed to control the cutting speed and length. Feed extruder machine has high output and stable operation. The main components are made of alloy materials and refined through heat treatment. It has the characteristics of high wear resistance and long service life.

Application

1.

Feed extruder machine uses corn, soybean (bean cake) animal scraps, etc. as raw materials, and is suitable for the production of feed with different pet flavors such as dogs, cats, fish, birds, rabbits, shrimps, dogs, cats, minks, foxes, etc.

2.

Feed extruder machine is suitable for farmers and small and medium-sized feed factories.The feed is neatly formed and smooth, it floats on the water surface without sinking for more than 12 hours, does not pollute water sources, and sterilizes to reduce fish diseases.

Features

1. The density of pet feed and aquatic feed can be controlled.

2. Dry puffing process adopts self-heating method and does not require steam system.

3. The screw design has powerful self-cleaning function.

4. Variable speed cutting head, adjustable gap between cutter and template.

5. The machine has novel design, compact structure and high production efficiency.

Parameter

| Model | Productivity (t/h) | Host power (kw) | Feeding power(kw) | Spiral diameter(mm) |

Cutting power (kw) |

Packing size | Weight |

| GD-PDFM-40 | 0.04-0.05 | 5.5kw(220v) | 0.4 | Φ40 | 0.4 | 1.36*1.60*0.85m | 350kg |

| GD-PDFM-50 | 0.08-0.09 | 11kw(380v) | 0.4 | Φ50 | 0.4 | 1.36*1.60*0.85m | 350kg |

| GD-PDFM-60 | 0.12-0.15 | 15 | 0.4 | Φ60 | 0.4 | 1.36*1.67*0.85m | 450kg |

| GD-PDFM-702 | 0.18-0.20 | 18.5 | 0.4 | Φ70 | 0.4 | 1.36*1.67*0.85m | 490kg |

| GD-PDFM-703 | 0.20-0.25 | 18.5 | 0.4 | Φ70 | 0.4 | 1.36*1.67*0.85m | 490kg |

| GD-PDFM-80 | 0.3-0.35 | 22 | 0.55 | Φ80 | 0.55 | 1.36*1.95*0.84m | 600kg |

| GD-PDFM-100 | 0.4-0.5 | 37 | 1.1 | Φ90 | 1.5 | 1.8*2.6*1.15m | 800kg |

| GD-PDFM-120 | 0.60-0.70 | 55 | 1.1 | Φ120 | 2.2 | 2.2*2.8*1.2m | 950kg |

| GD-PDFM-135 | 0.75-0.8 | 75 | 1.1 | Φ133 | 2.2 | 2.2*2.8*1.2m | 950kg |

| GD-PDFM-160 | 1.0-1.2 | 90 | 1.5 | Φ160 | 2.2 | 2.3*3.0*1.2m | 1200kg |

| GD-PDFM-200 | 1.8-2.0 | 110 | 2.2 | Φ160 | 2.2 | 2.4*3.2*1.4m | 1450kg |

Q1 What is a feed extruder?

A feed extruder is a piece of equipment used for processing animal feeds. It alters the physical and chemical properties of feed ingredients through high-temperature, high-pressure conditions and mechanical shear forces to enhance their solubility, digestibility, and texture, thereby improving feed utilization by animals.

Q2 How does a feed extruder work?

A feed extruder works by pushing feed ingredients into an extrusion screw and then subjecting them to high temperatures and pressures to extrude the materials. During extrusion, the materials expand and generate heat, causing starch gelatinization and protein denaturation, thereby increasing their solubility and digestibility.

Q3 What are the applications of feed extruders?

Feed extruders are widely used in the production of feed for poultry, livestock, and aquaculture. They can also be used in the manufacturing of pet food and other industrial processing applications.

Q4 What are the advantages of using a feed extruder?

Feed extruders can improve the texture, nutritional value, and stability of feed. They can eliminate some harmful microorganisms and anti-nutritional factors, enhance animals' utilization of feed, and reduce feed wastage.

Q5 What should be considered in the maintenance of a feed extruder?

Maintenance of a feed extruder is crucial to ensure its proper functioning. Regular cleaning and inspection of components, ensuring proper lubrication systems, and following manufacturer-recommended maintenance schedules are important.

Installing waterproof membrane to reduce dust and water pollution

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation

Delivery Time

For stock type, we can send within 48hrs after confirming order.

For customized type , delivery date need to be negotiated before taking order.