Siemens touch screen,Powerful, color touch screen control, Chinese and English optional operating interface, convenient and

intuitive, powerful data memory function, can store multiple groups of labeling parameters, with production counting function, power saving function. Production number setting prompt function, parameter setting protection function, convenient production management, different product labeling switch one key to achieve, without repeated debugging, simple and fast; And has the perfect fault prompt and the help function.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

YIMU

-

Dimension(L*W*H):

-

2000(L)*700(W)*1720(H) mm

-

Weight:

-

250 KG

-

Product name:

-

automatic lighter top side soap box toothbrush label machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Labeling speed:

-

20-150 Bottles/min

-

Suitable for label width:

-

5-180mm

-

Suitable for label length:

-

5-350mm

-

Labeling accuracy:

-

0.5mm

-

Function:

-

Labeling on top side

-

Material:

-

SS304 Stainless Steel

-

Control system:

-

Japanese Mitsubishi PLC

-

Keyword:

-

Top flat plane labeling machine

-

Marketing Type:

-

Other

Quick Details

-

Application:

-

Food, Beverage, Commodity, Chemical, Machinery & Hardware

-

Packaging Type:

-

Cartons

-

Packaging Material:

-

Wood

-

Voltage:

-

220/380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

YIMU

-

Dimension(L*W*H):

-

2000(L)*700(W)*1720(H) mm

-

Weight:

-

250 KG

-

Product name:

-

automatic lighter top side soap box toothbrush label machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Labeling speed:

-

20-150 Bottles/min

-

Suitable for label width:

-

5-180mm

-

Suitable for label length:

-

5-350mm

-

Labeling accuracy:

-

0.5mm

-

Function:

-

Labeling on top side

-

Material:

-

SS304 Stainless Steel

-

Control system:

-

Japanese Mitsubishi PLC

-

Keyword:

-

Top flat plane labeling machine

-

Marketing Type:

-

Other

Products Description

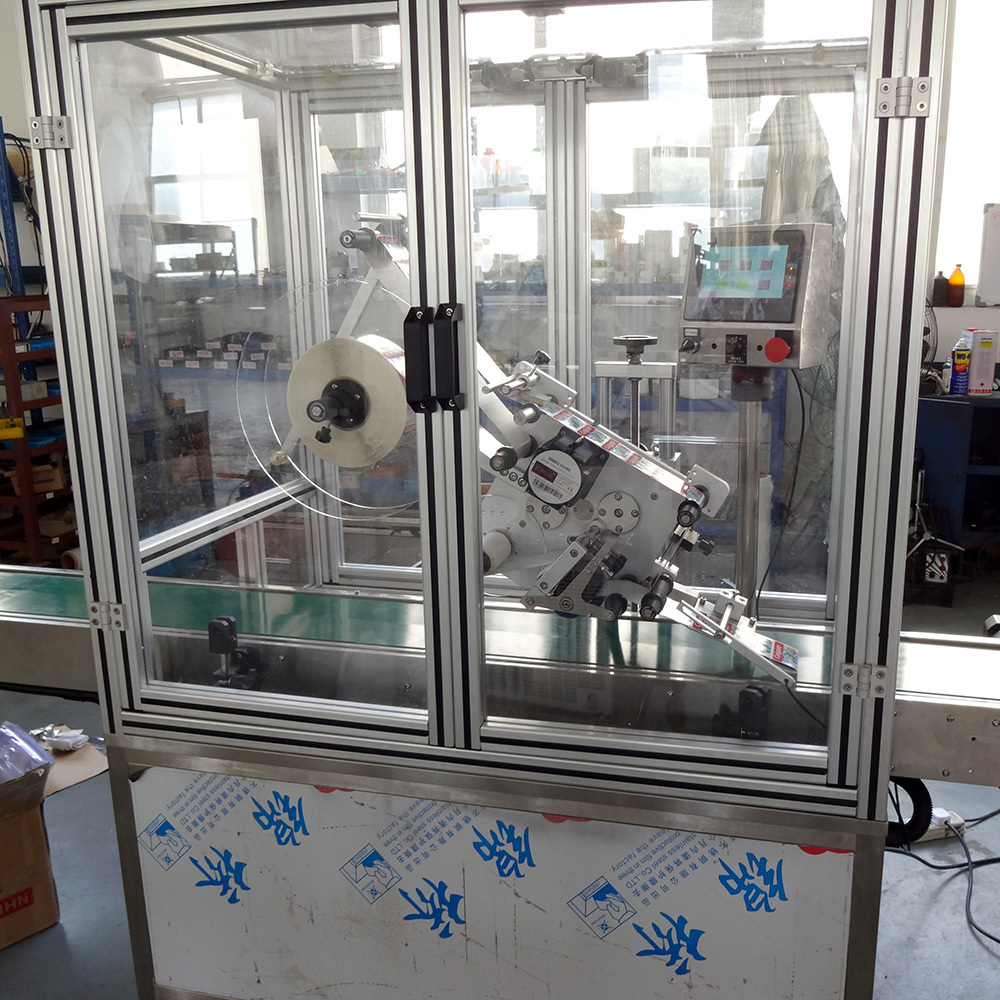

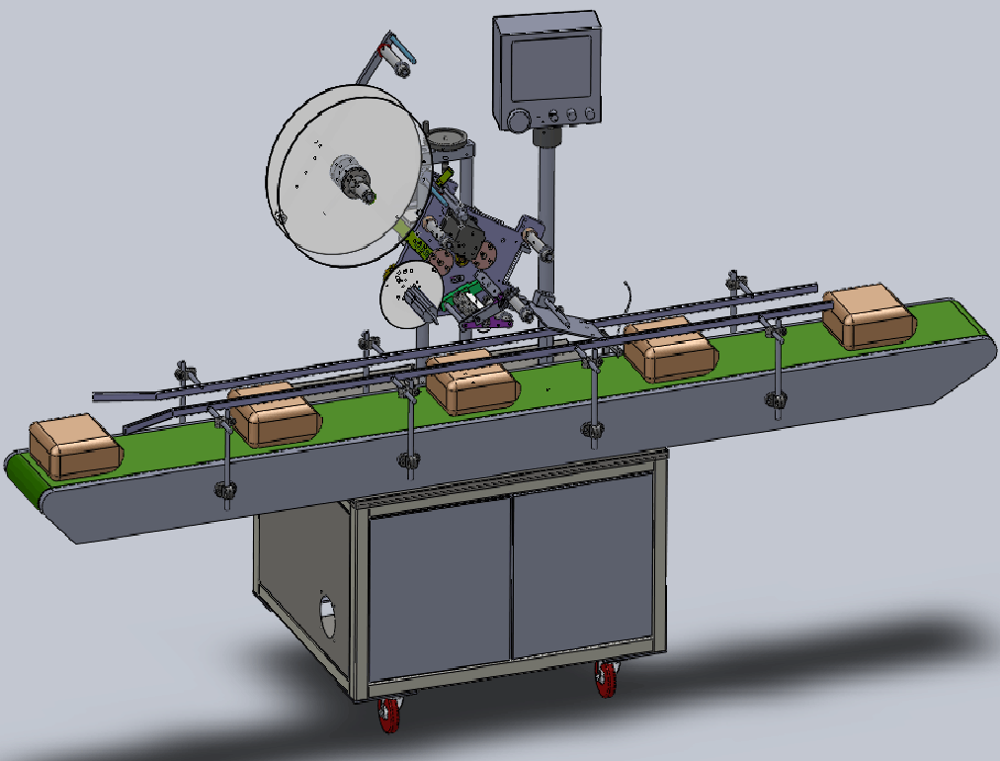

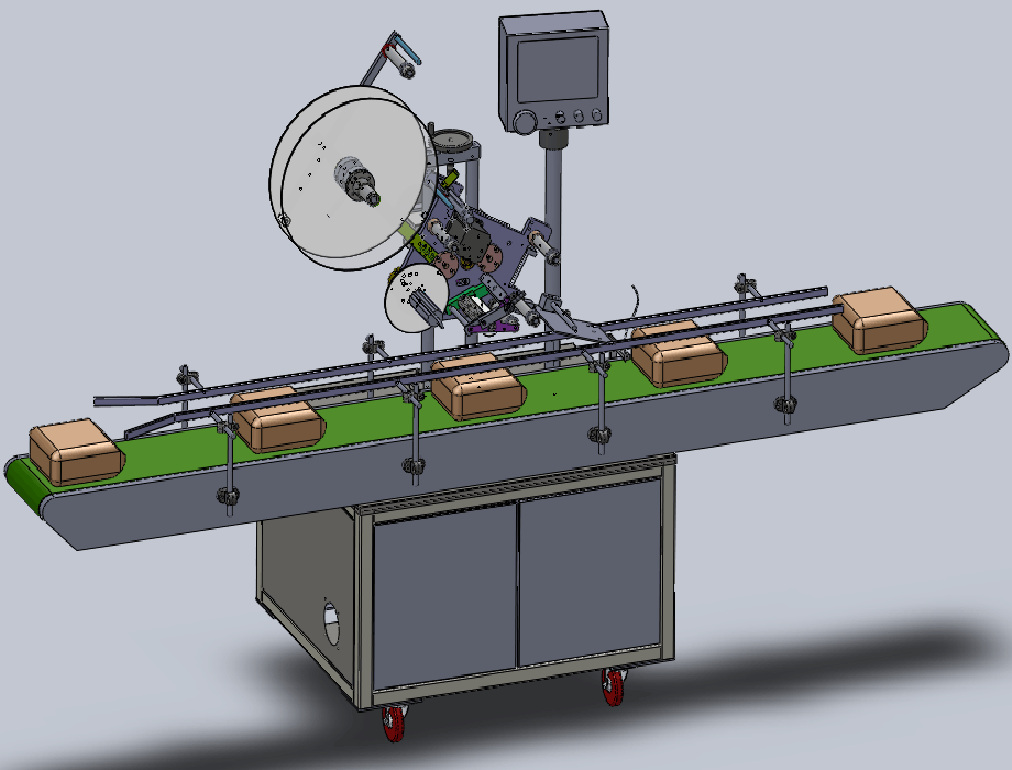

1.Machine suitable for any top side flat product labeling.

2.PLC and touch screen control panel with easy operation, many units parameter setting and save.

3.Automatic stop when label breaks down or runs out, Malfunction self-testing and display with alarm.

4.Machine can use alone or connect with filling packing line use.

5. All components are precisely processed by CNC to ensure high quality.

2.PLC and touch screen control panel with easy operation, many units parameter setting and save.

3.Automatic stop when label breaks down or runs out, Malfunction self-testing and display with alarm.

4.Machine can use alone or connect with filling packing line use.

5. All components are precisely processed by CNC to ensure high quality.

6. All electrical configurations are big international brand, such as Simens, Mitsubishi, WEINVIEW, Danfoss, Schneider, Yaskawa,Keyence, Omron, SMC and so on.

7.Very high labeling accuracy, long-time using.

7.Very high labeling accuracy, long-time using.

Product Paramenters

|

Model

|

YM210

|

|

Capacity (PCS/min)

|

0-100(depond on bottle and label size)

|

|

Conveyor running side

|

from left to right / from right to left

|

|

Conveyor speed(meter/min)

|

≤40

|

|

Labeling error

|

< ±0.3mm

|

|

The inner diameter of label roll

|

76 mm

|

|

The outer diameter of label roll

|

360 mm(max)

|

|

Suitable for label size

|

W:5-300mm, L:10-500mm

|

|

Suitable size of labeling objects

|

any size

|

|

Power supply(In China)

|

AC220V 50/60HZ single phase (customized)

|

|

Power

|

400W

|

|

Weight

|

200 KG

|

|

Machine size

|

2000(L) 800 (W) 1650 (H) mm

|

Details Images

Touch screen

PLC control system

Adopt Japanese Mitsubishi PLC control system, a more stable performance, Keep the machine safe and running steadily.

Bottle Dispersing

The application is flexible , the bottle standing type labeling machine is provided with an automatic bottle separating function, can be produced in a single machine , and also can be connected with the production line .

Machine Parts

Certifications

Company Introduction

Our Customers

Ratings & Reviews

Packaging&Shipping

Recommend Products

FAQ

Q1:Are you a factory or trading company?

A1:We are a factory specializing in the production of packing machine.Q2:How long is the delivery date?

A2:The delivery date is about 15-40 working days.

Q3:What is payment term?

A3:Deposit 30% in advance and 70% before shipment the machine.

Q4:How can you guarantee quality?

A4:1.We will test strictly after the machine completed.

2.Our machine are certified by SGS.

3.Our different workers are responsible for different production processes to ensure that everyone’s work is in place.

4.We have our own inspection team.The inspectors will operate and test after the machine is completed.

5.So farceur company has not had a single quality complaint, and the customers satisfaction is 100%.

Q5:How can I know your machine is designed for my product?

A5:You can send us samples of your product and we test it on machine, and take care of your all needs.

Q6:Is there any installation direction after we received the machine?

A6: Yes of course, and we have a professional technical team and warm after service.And we can solve any problem you meet during

the installation and packing production in time.

A1:We are a factory specializing in the production of packing machine.Q2:How long is the delivery date?

A2:The delivery date is about 15-40 working days.

Q3:What is payment term?

A3:Deposit 30% in advance and 70% before shipment the machine.

Q4:How can you guarantee quality?

A4:1.We will test strictly after the machine completed.

2.Our machine are certified by SGS.

3.Our different workers are responsible for different production processes to ensure that everyone’s work is in place.

4.We have our own inspection team.The inspectors will operate and test after the machine is completed.

5.So farceur company has not had a single quality complaint, and the customers satisfaction is 100%.

Q5:How can I know your machine is designed for my product?

A5:You can send us samples of your product and we test it on machine, and take care of your all needs.

Q6:Is there any installation direction after we received the machine?

A6: Yes of course, and we have a professional technical team and warm after service.And we can solve any problem you meet during

the installation and packing production in time.

Hot Searches