Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

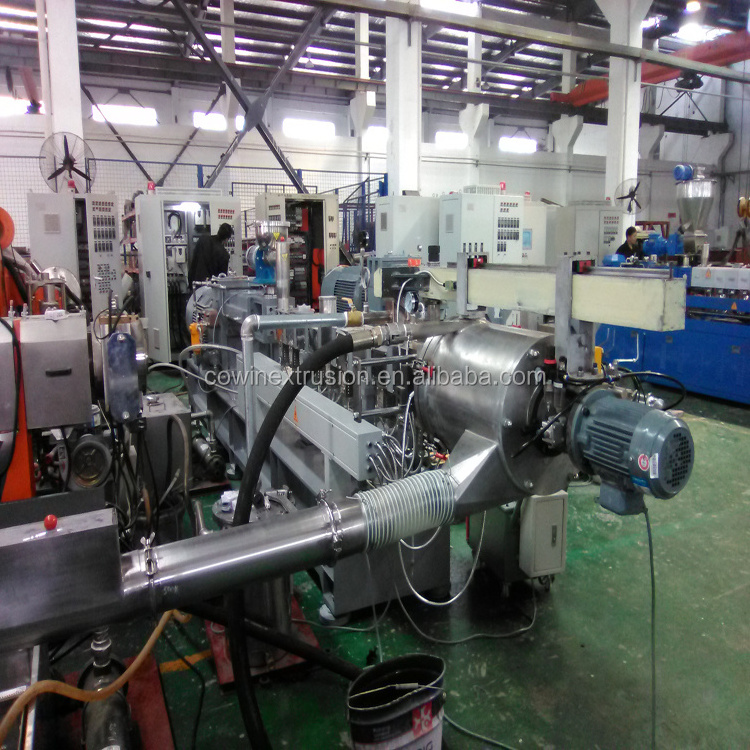

Jiangsu, China

-

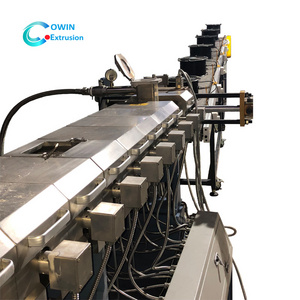

Brand Name:

-

Cowin

-

Voltage:

-

Customer Standard

-

Dimension(L*W*H):

-

Machine Model

-

Power (kW):

-

800

-

Weight:

-

100 KG, 100 800 kg

-

Applicable Industries:

-

polymer compounding

-

After sales Service Provided:

-

Engineers available to service machinery overseas

-

After Warranty Service:

-

Video technical support

-

Marketing Type:

-

Hot Product 2021

Quick Details

-

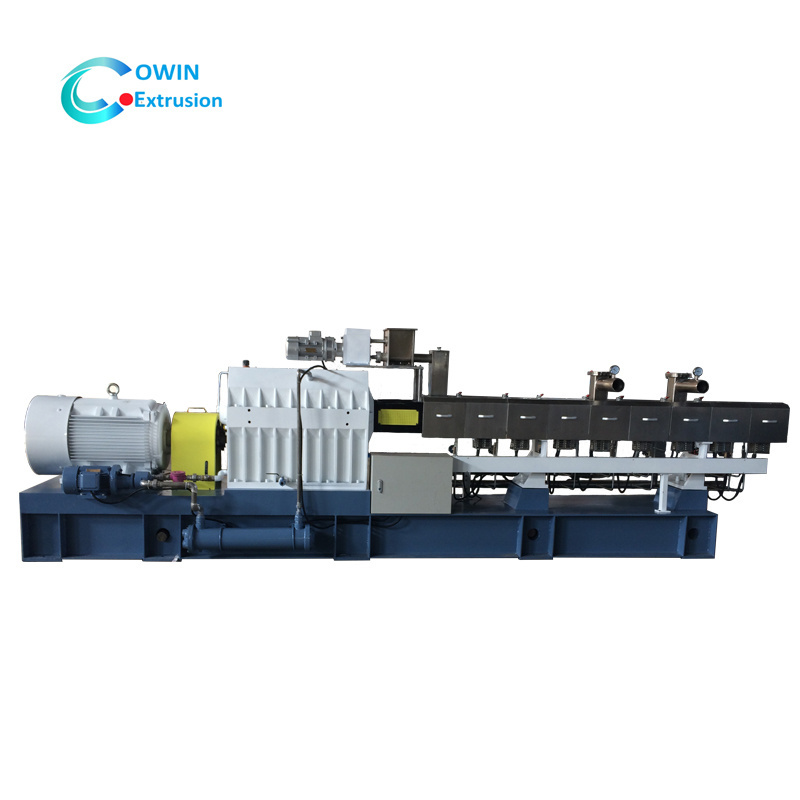

Screw Design:

-

Other

-

Screw L/D Ratio:

-

Other

-

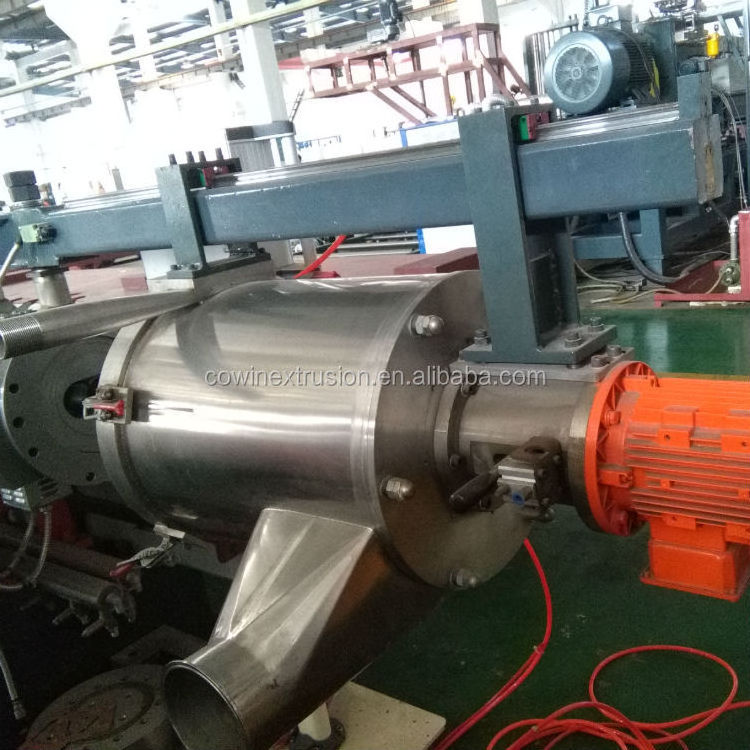

Screw diameter (mm):

-

71 mm

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Cowin

-

Voltage:

-

Customer Standard

-

Dimension(L*W*H):

-

Machine Model

-

Power (kW):

-

800

-

Weight:

-

100 KG, 100 800 kg

-

Applicable Industries:

-

polymer compounding

-

After sales Service Provided:

-

Engineers available to service machinery overseas

-

After Warranty Service:

-

Video technical support

-

Marketing Type:

-

Hot Product 2021

Water ring pelletizer is suitable for the pelletizing of most thermoplastics, including filled and reinforced products, such as:

(1) PE, EVA etc. filled with CaCO3, talc, TiO2, carbon black etc.

(2) Cable sheath, cable insulation compounds of LDPE, HDPE, LLDPE, or MDPE

(3) Radiation-crosslinkable, heat-shrinkable cable compounds

(4) PPR pipe compounds, PE compounds for crosslinked pipes; TPR, TPU, TPV thermoplastic elastomers; EVA and hot-melt adhesives

(5) Color concentrates of PE, ABS, PS, EVA, etc.

(6) Flame retardant master batches of ABS, EVA etc.

(7) Master batches with PE, PP, PS etc as carriers for degradation applications

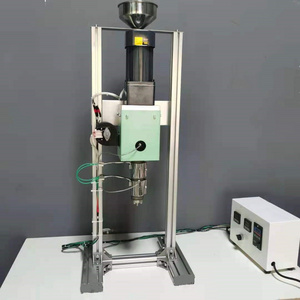

In water ring pelletizers, the cooling and transport medium, water, does not come into contact with the die plate. The circulating knives cut the melt strands and fling the hot molten pellets into the circulating water ring. The water flow conveys the pellets out of the pelletizer hood.

SPECIFICATION

|

Machine model |

Screw diameter (mm) |

Screw speed (r/min) |

Motor power (kw) |

Torque (N.M) |

Specific torque (T/A3) |

Output (kg/h) |

|

|

CHT-20 |

A |

22 |

400 |

4 |

48 |

7.6 |

1~10 |

|

B |

22 |

500 |

5.5 |

52 |

8.4 |

5~15 |

|

|

C |

22 |

600 |

7.5 |

59 |

9.6 |

10~20 |

|

|

D |

22 |

750 |

11 |

70 |

11.2 |

15~30 |

|

|

CHT-30 |

A |

30 |

300 |

11 |

175 |

9.9 |

15~30 |

|

B |

30 |

400 |

15 |

180 |

10.2 |

30~50 |

|

|

C |

30 |

500 |

18.5 |

176 |

10 |

40~60 |

|

|

D |

30 |

600 |

22 |

175 |

9.9 |

60~80 |

|

|

CHT-40 |

A |

41 |

300 |

30 |

477 |

11.6 |

80~100 |

|

B |

41 |

400 |

37 |

441 |

10.7 |

100~120 |

|

|

C |

41 |

500 |

45 |

429 |

10.5 |

120~150 |

|

|

D |

41 |

600 |

55 |

437 |

10.6 |

150~180 |

|

|

CHT-52 |

A |

51.4 |

300 |

45 |

716 |

9 |

120~150 |

|

B |

51.4 |

400 |

55 |

656 |

8.3 |

150~180 |

|

|

C |

51.4 |

500 |

75 |

716 |

9 |

250~280 |

|

|

D |

51.4 |

600 |

90 |

716 |

9 |

280~300 |

|

|

CHT-65 |

A |

62.4 |

300 |

90 |

1432 |

10.2 |

280~300 |

|

B |

62.4 |

400 |

110 |

1313 |

9.3 |

300~400 |

|

|

C |

62.4 |

500 |

132 |

1260 |

8.9 |

400~500 |

|

|

D |

62.4 |

600 |

160 |

1273 |

9.1 |

500~600 |

|

|

CHT-75 |

A |

71 |

300 |

132 |

2101 |

9.7 |

400~500 |

|

B |

71 |

400 |

160 |

1910 |

8.8 |

500~600 |

|

|

C |

71 |

500 |

220 |

2101 |

9.7 |

600~700 |

|

|

D |

71 |

600 |

250 |

1990 |

9.2 |

800~1000 |

|

|

CHT-85 |

A |

81 |

300 |

185 |

2944 |

9.4 |

600~700 |

|

B |

81 |

400 |

250 |

2984 |

9.6 |

800~1000 |

|

|

C |

81 |

500 |

315 |

3008 |

9.6 |

1000~1200 |

|

|

D |

81 |

600 |

350 |

2902 |

9.3 |

1000~1500 |

|

|

CHT-95 |

A |

93 |

300 |

280 |

4456 |

9.4 |

900~1100 |

|

B |

93 |

400 |

355 |

4237 |

9 |

1000~1200 |

|

|

C |

93 |

500 |

450 |

4297 |

9 |

1200~1500 |

|

|

D |

93 |

600 |

550 |

4377 |

9.2 |

1500~2000 |

|

|

CHT-135 |

A |

133 |

300 |

400 |

6366 |

4.8 |

1000~1300 |

|

B |

133 |

400 |

550 |

6565 |

4.9 |

1100~1600 |

|

|

C |

133 |

500 |

650 |

6207 |

4.7 |

1500~2200 |

|

|

D |

133 |

600 |

800 |

6366 |

4.8 |

2000~3000 |

|

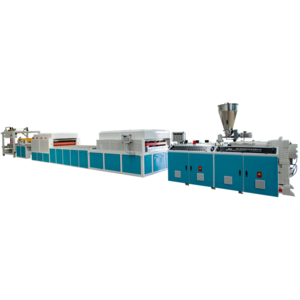

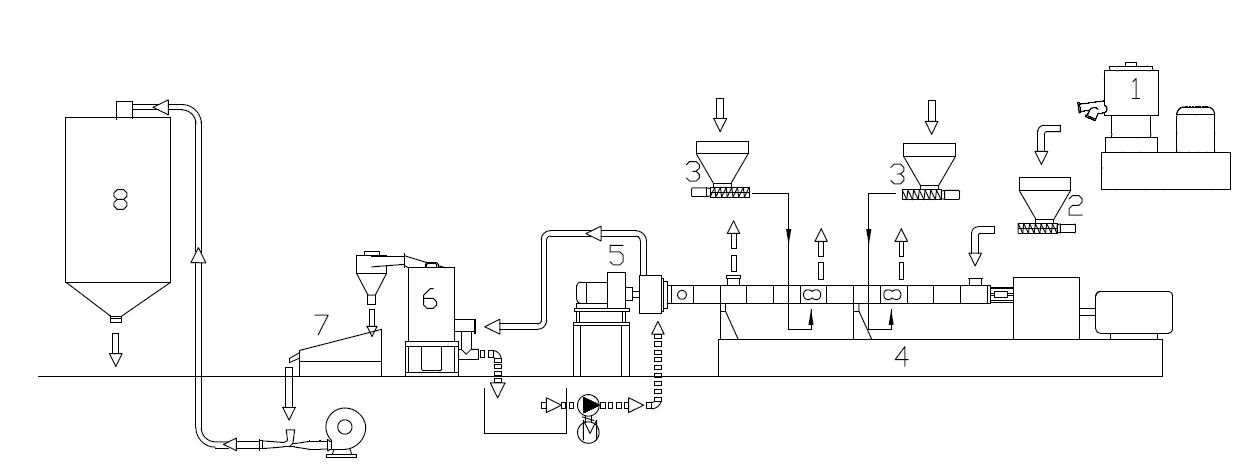

FLOW CHART

1. high-speed mixer 2. main feeder 3. side feeder 4.twin screw extruder 5. water-ring granulator 6. centrifugal dewatering

7. vibrating sieve 8. silo