- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≤±50g

-

Voltage:

-

220V 50HZ, 220v 50hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TOPCN

-

Dimension(L*W*H):

-

150*90*150cm

-

Weight:

-

350 KG

-

Filling volume(weight):

-

5-30L

-

Filling speed:

-

5-10 barrel/min

-

Air consumption:

-

0.6m³/h

-

Bottle height:

-

300mm-500mm

-

Power:

-

Total 1KW

-

Filling nozzles:

-

1/2

-

Capacity:

-

300-600bph

-

Air pressure:

-

0.6-0.8Mpa

-

Bottle dia:

-

250mm-350mm

Quick Details

-

Machinery Capacity:

-

200BPH, 600BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

≤±50g

-

Voltage:

-

220V 50HZ, 220v 50hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TOPCN

-

Dimension(L*W*H):

-

150*90*150cm

-

Weight:

-

350 KG

-

Filling volume(weight):

-

5-30L

-

Filling speed:

-

5-10 barrel/min

-

Air consumption:

-

0.6m³/h

-

Bottle height:

-

300mm-500mm

-

Power:

-

Total 1KW

-

Filling nozzles:

-

1/2

-

Capacity:

-

300-600bph

-

Air pressure:

-

0.6-0.8Mpa

-

Bottle dia:

-

250mm-350mm

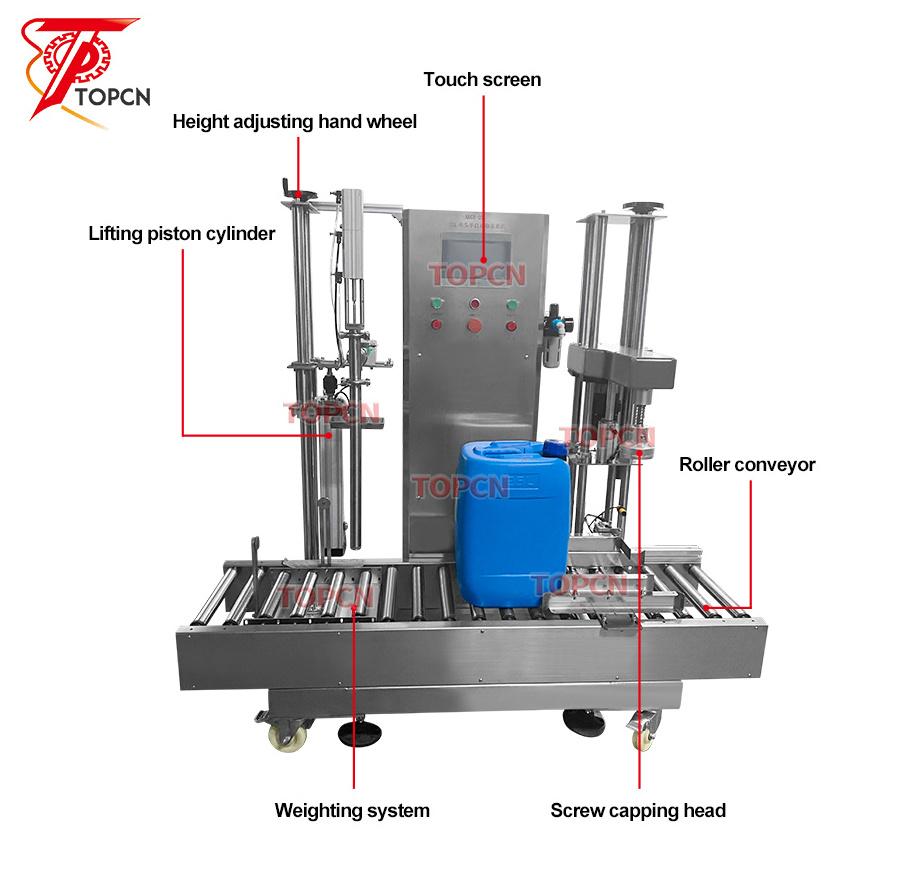

Application:

The filling and capping is widely used for all kinds of big bucket paint, ink, car paint, furniture paint, Tiana water, adhesive (glue), resin, chemical solvent, lubricating oil, shoe glue, and other liquid

Specification:

1:The control system adopts the high-end electrical parts such as programmable controller I/O PLC module, which has reliable performance and low maintenance cost.

2: The sealing and soft connection uses Teflon, which is solvent resistant, acid and alkali resistant and has long service life.

3. The system adopts two-stage adjustable filling mode for the large and small materials, which improves the accuracy and productivity.

4. The filling quantity can be set freely, which is suitable for quantitative filling in various weight ranges.

5. Full Touch Screen is English Animation Operation, Full Teaching Mode Operation Guidance, Display Target Quantity, Filling Quantity, Bucket Number, Cumulative Quantity and so on.

6.The system uses all-English guided operation to memorize working group parameters and formulas. Maximum storage of 100 sets of parameters,.

7. The device can extend the Ethernet interface/DP/NET interface to facilitate centralized control and integrated monitoring of factory data in the later

|

Parameter

|

|

|

|

|||

|

Weight

|

350kg

|

Dimensions of weighting

|

350*350mm

|

|||

|

Voltage

|

220V/50HZ

|

Power

|

Total 1KW

|

|||

|

Filling volume(weight)

|

5 litres to 30 litres

|

Filling nozzles

|

1/2 SUS304/SUS316/PTFE

|

|||

|

Filling speed

|

5-10 barrel/min

|

Filling precision

|

±50g

|

|||

|

Air consumption

|

0.6m³/h

|

Air pressure

|

0.6-0.8Mpa

|

|||

|

Bottle height

|

300mm-500mm

|

Bottle dia

|

250mm-350mm

|

|||

Stainless steel filling head has anti-drop design, It promise do not waste the material. And diameter of filling head basis on the diameter of customer’s barrel’s mouth.

Filling head with weighting can do as customer capacity,stainless steel filling nozzles, using life is longer,Each filling head can work separately.

Advantages of our products: the plate thickness is 3.01m.

When bottle capping,the sensor will touch the bottle, and steel clamping plate will fix the can automatic capping,

Related Products

■

1. A step-by-step free English manual and operation video to easily know how to operate the machine.

■

2. Our senior engineers are skillful and fluent in English. They have rich oversea experiences and are available to oversea services. Below with some pictures our engineers trained customers how to install and operate the machines.

Hot Searches