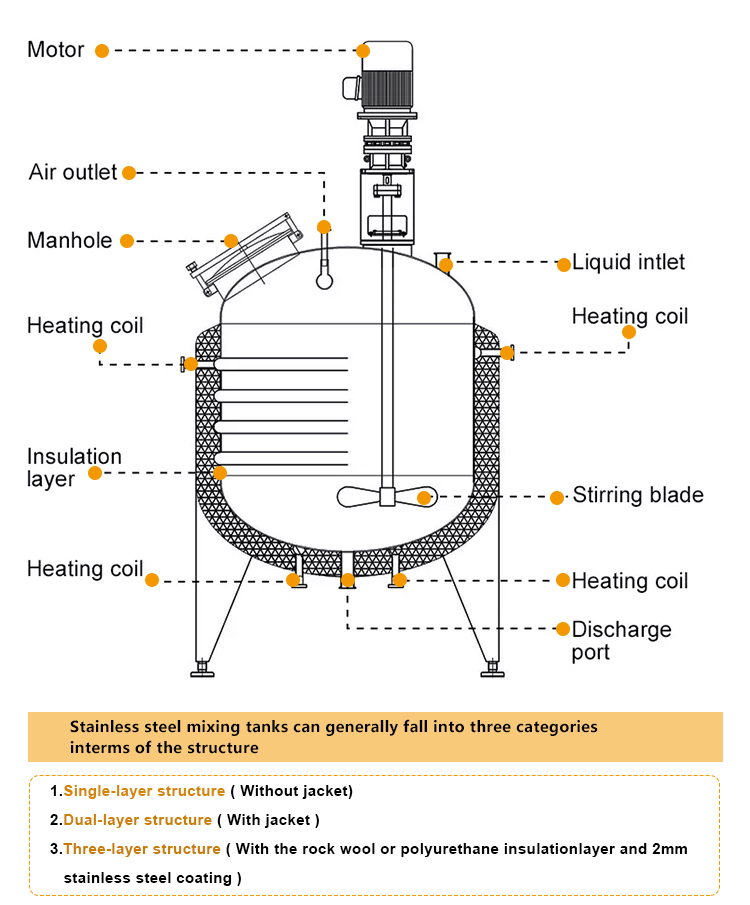

A mixing tank, also known as water-phase tank, is widely used in paint, building materials, chemical, pigment, resin, food,scientific research and other industries. The device can be made of carbon steel, stainless steel and other material as well as be equipped with heating and cooling devices according to different process requirements and production needs of users. A mixing tank is a kind of vessel that can perform stirring, mixing, blending, homogenizing and other operations for material. According to different requirements of production processes, different structures and configurations can be designed, and standardized and humanized production can be satisfied as well. The heating modes concludes electric heating of jacket and coil heating. Featuring reasonable structure, advanced technology, durability, simple operation and convenient use, it is regarded as an ideal chemical device that can invest little, put into production quickly and gain high interest. It can realize the charging control, discharging control, stirring control and manual and automatic control during the mixing.

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

150 KG

-

Place of Origin:

-

China

-

Brand Name:

-

INTOP

-

Voltage:

-

380V50HZ

-

Power (kW):

-

0.75 kW

-

Product name:

-

Mayonnaise Agitator tank

-

After-sales Service Provided:

-

Online Support

-

Applicable Materials:

-

FOOD

-

Filling Accuracy:

-

≤±1-2%

Quick Details

-

Barrel Volume (L):

-

100

-

Max. Loading Volume (L):

-

100 L

-

Range of Spindle Speed(r.p.m):

-

0 - 300 r.p.m

-

Weight (KG):

-

150 KG

-

Place of Origin:

-

China

-

Brand Name:

-

INTOP

-

Voltage:

-

380V50HZ

-

Power (kW):

-

0.75 kW

-

Product name:

-

Mayonnaise Agitator tank

-

After-sales Service Provided:

-

Online Support

-

Applicable Materials:

-

FOOD

-

Filling Accuracy:

-

≤±1-2%

Product Description

Mayonnaise Agitator tank

Product Description

A mixing tank, also known as water-phase tank, is widely used in paint, building materials, chemical, pigment, resin, food,scientific research and other industries. The device can be made of carbon steel, stainless steel and other material as well as be equipped with heating and cooling devices according to different process requirements and production needs of users. A mixing tank is a kind of vessel that can perform stirring, mixing, blending, homogenizing and other operations for material. According to different requirements of production processes, different structures and configurations can be designed, and standardized and humanized production can be satisfied as well. The heating modes concludes electric heating of jacket and coil heating. Featuring reasonable structure, advanced technology, durability, simple operation and convenient use, it is regarded as an ideal chemical device that can invest little, put into production quickly and gain high interest. It can realize the charging control, discharging control, stirring control and manual and automatic control during the mixing.

A mixing tank, also known as water-phase tank, is widely used in paint, building materials, chemical, pigment, resin, food,scientific research and other industries. The device can be made of carbon steel, stainless steel and other material as well as be equipped with heating and cooling devices according to different process requirements and production needs of users. A mixing tank is a kind of vessel that can perform stirring, mixing, blending, homogenizing and other operations for material. According to different requirements of production processes, different structures and configurations can be designed, and standardized and humanized production can be satisfied as well. The heating modes concludes electric heating of jacket and coil heating. Featuring reasonable structure, advanced technology, durability, simple operation and convenient use, it is regarded as an ideal chemical device that can invest little, put into production quickly and gain high interest. It can realize the charging control, discharging control, stirring control and manual and automatic control during the mixing.

Specification

|

Capacity

|

Custom plastic syringes

|

100L

|

|

|

Motor power

|

5-80ml

|

0.75kw three-phase power 380V50HZ

|

|

|

Equipped

|

Japanese import customization

|

reducer

|

|

|

Material

|

≤ 60 decibels

|

304 stainless steel

|

|

|

Surface treatment

|

1800-2700 branches / h

|

inside and outside brushed surface

|

|

|

Inner bucket size

|

3kw

|

diameter 600mm high 500mm

|

|

|

Blade

|

380V/220V 50-60Hz

|

frame type with wall scraping

|

|

|

Rotation speed

|

0.55-0.75Mpa 20L/S

|

300r/min

|

|

|

Opening method

|

L1252×W950×H1785mm

|

Double open lid

|

|

|

Thickness

|

500kg

|

2t

|

|

Details Images

It can be customized according to your needs, please contact us !!!

Application

This equipment is mainly used in storing material used in food, chemical industries and it is indispensable storage equipment for them.

Customer Photos

Packing & Delivery

Packaging Details:

We will make different packaging according to different machine sizes .standard international export packing, container, wooden box.

Delivery Time:

We will customize according to the actual needs of customers. Senior designers start to design the plan. After receiving the deposit, we will complete the delivery within 20 to 30 working days.

Hot Searches