- Product Details

- {{item.text}}

Quick Details

-

Elongation (≥ %):

-

/

-

Place of Origin:

-

Shandong, China

-

Application:

-

Industry construction building

-

Grade:

-

Nickel Alloy

-

Ni (Min):

-

balance

-

Brand Name:

-

Juzhou

-

Surface finish::

-

Annealed, polished etc.

-

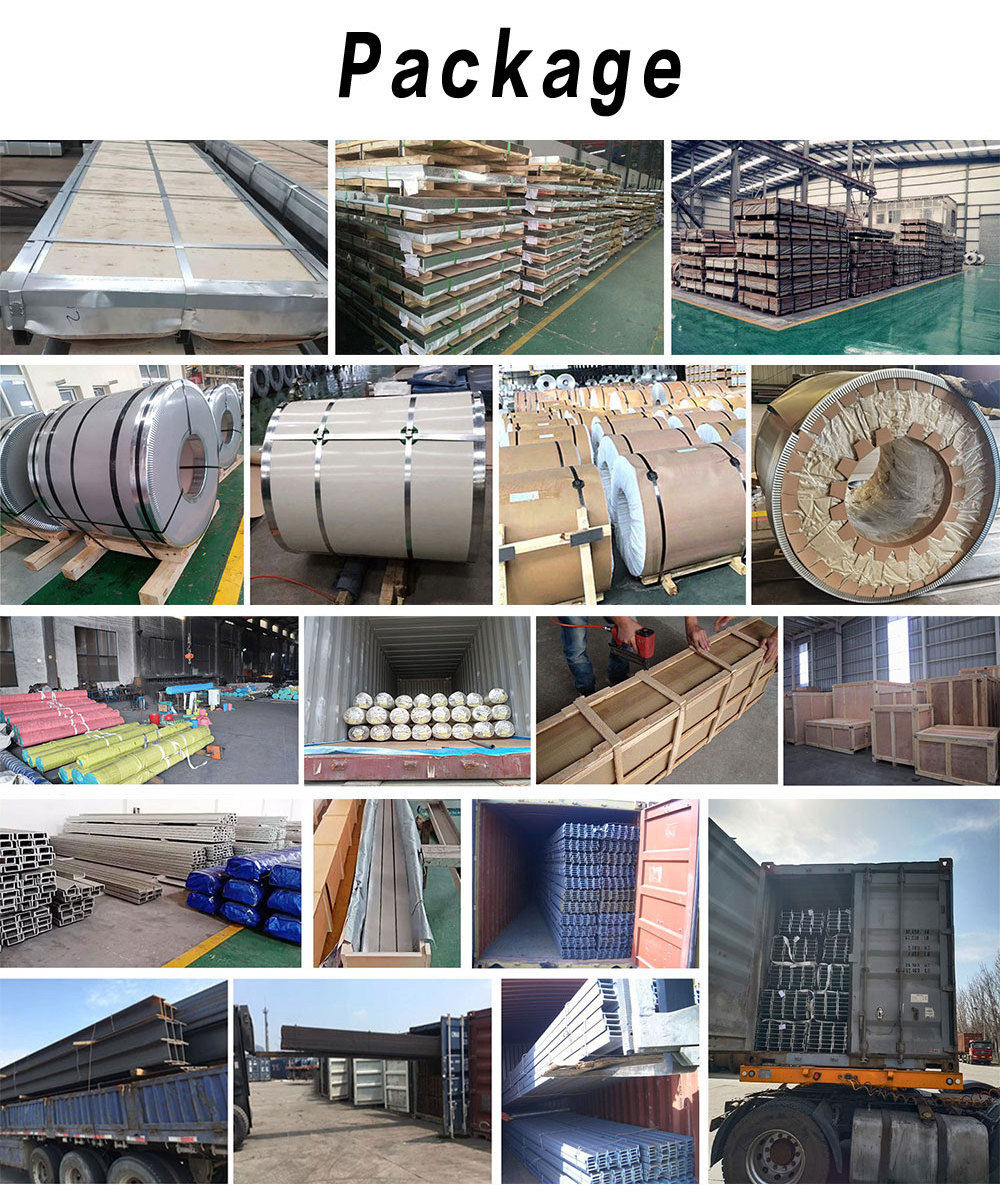

Packing:

-

Standard Sea-worthy Package

-

MOQ:

-

5 Tons

-

Supply Ability:

-

50000 Ton/Tons per Month

Quick Details

-

Resistance (μΩ.m):

-

/

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

/

-

Elongation (≥ %):

-

/

-

Place of Origin:

-

Shandong, China

-

Application:

-

Industry construction building

-

Grade:

-

Nickel Alloy

-

Ni (Min):

-

balance

-

Brand Name:

-

Juzhou

-

Surface finish::

-

Annealed, polished etc.

-

Packing:

-

Standard Sea-worthy Package

-

MOQ:

-

5 Tons

-

Supply Ability:

-

50000 Ton/Tons per Month

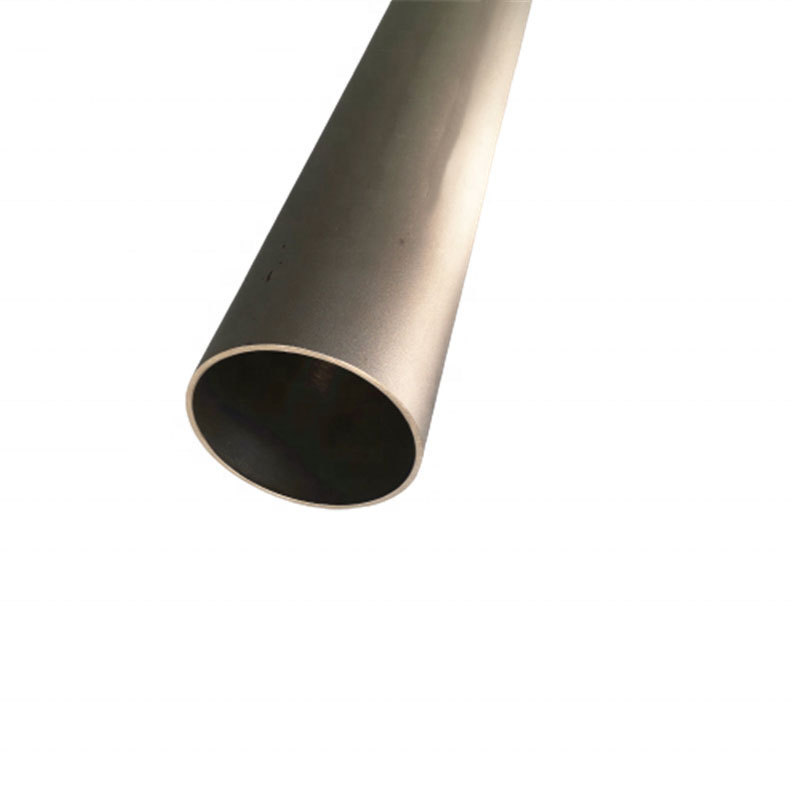

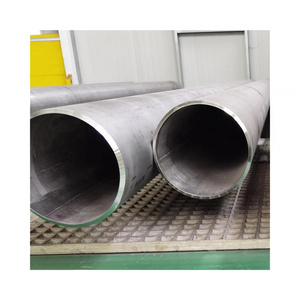

Product Introduction

|

Product Name

|

Alloy 625 N06625 Seamless pipe seamless tube Alloy 825 Alloy C276 nickel alloy small MOQ seamless pipe

|

|

Standard

|

GB,AISI,ASTM,DIN,EN,JIS

|

|

Grade

|

Stainless steel 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 /

S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etc |

|

|

Monel 400 / Monel K-500

|

|

|

Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750

|

|

|

Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incoloy 800HT

|

|

|

Incoloy 825 / Incoloy 901 / Incoloy 925 / Incoloy 926

|

|

|

Nimonic 75 / Nimonic 80A / Nimonic 90 / Nimonic 105 / Nimonic C263 / L-605

|

|

|

Hastelloy B / Hastelloy B-2 / Hastelloy B-3 / Hastelloy C / Hastelloy C-276 / Hastelloy C-22

|

|

|

Hastelloy C-4 / Hastelloy C-2000 / Hastelloy G-35 / Hastelloy X / Hastelloy N

|

|

|

PH stainless steel 15-5PH / 17-4PH / 17-7PH

|

|

Inspection

|

TUV,SGS,BV,ABS,LR and so on

|

|

Application

|

Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, Chemical Fertilizer,

Sewage Disposal, Desalination, Waste Incineration etc. |

Material introduction

Alloy c2000 this alloy is designed to resist more corrosive chemical substances, including sulfuric acid, hydrochloric acid,

chlorofluoroic acid. different from the previous optimized ni-cr-mo alloy, which can simplest face up to oxidizing or reducing acids, c-2000 alloy has corrosion resistance in each environments. the mixed movement of molybdenum and copper (at 16% and 1.6% respectively) makes the alloy have great corrosion resistance in reducing medium, and the high chromium content material (23% wt) ensures the corrosion resistance in oxidizing medium.

Alloy c2000 this alloy is designed to resist more corrosive chemical substances, including sulfuric acid, hydrochloric acid,

chlorofluoroic acid. different from the previous optimized ni-cr-mo alloy, which can simplest face up to oxidizing or reducing acids, c-2000 alloy has corrosion resistance in each environments. the mixed movement of molybdenum and copper (at 16% and 1.6% respectively) makes the alloy have great corrosion resistance in reducing medium, and the high chromium content material (23% wt) ensures the corrosion resistance in oxidizing medium.

The minimum value of the mechanical properties of an alloy at room temperature

|

Alloys and states

|

Tensile strength

|

Yield strength

|

Extend rate

|

|

|

RM N/MM2

|

RP0.2N/MM2

|

A5%

|

|

Alloy C-2000

|

690

|

283

|

45

|

Product packaging

Hot Searches