- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

0-80mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DA PENG LASER

-

Weight (KG):

-

5600 KG

-

Product name:

-

Exchange Fiber Laser Cutter

-

Laser source type:

-

Fiber source

-

Cutting materials:

-

Stainless Steel Carbon Steel

-

Laser output power:

-

1500W/2000W/3000W

-

Cutting range:

-

3000*1500mm

-

Minimum line width:

-

<0.1mm

-

Cooling method:

-

Water cooling

-

X/Y Positioning Accuracy:

-

0.03mm

-

Transfer method:

-

Precision rack dual drive

-

Keywords:

-

Fiber Laser Metal Cutting Machine

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

140m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

0-80mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DA PENG LASER

-

Weight (KG):

-

5600 KG

-

Product name:

-

Exchange Fiber Laser Cutter

-

Laser source type:

-

Fiber source

-

Cutting materials:

-

Stainless Steel Carbon Steel

-

Laser output power:

-

1500W/2000W/3000W

-

Cutting range:

-

3000*1500mm

-

Minimum line width:

-

<0.1mm

-

Cooling method:

-

Water cooling

-

X/Y Positioning Accuracy:

-

0.03mm

-

Transfer method:

-

Precision rack dual drive

-

Keywords:

-

Fiber Laser Metal Cutting Machine

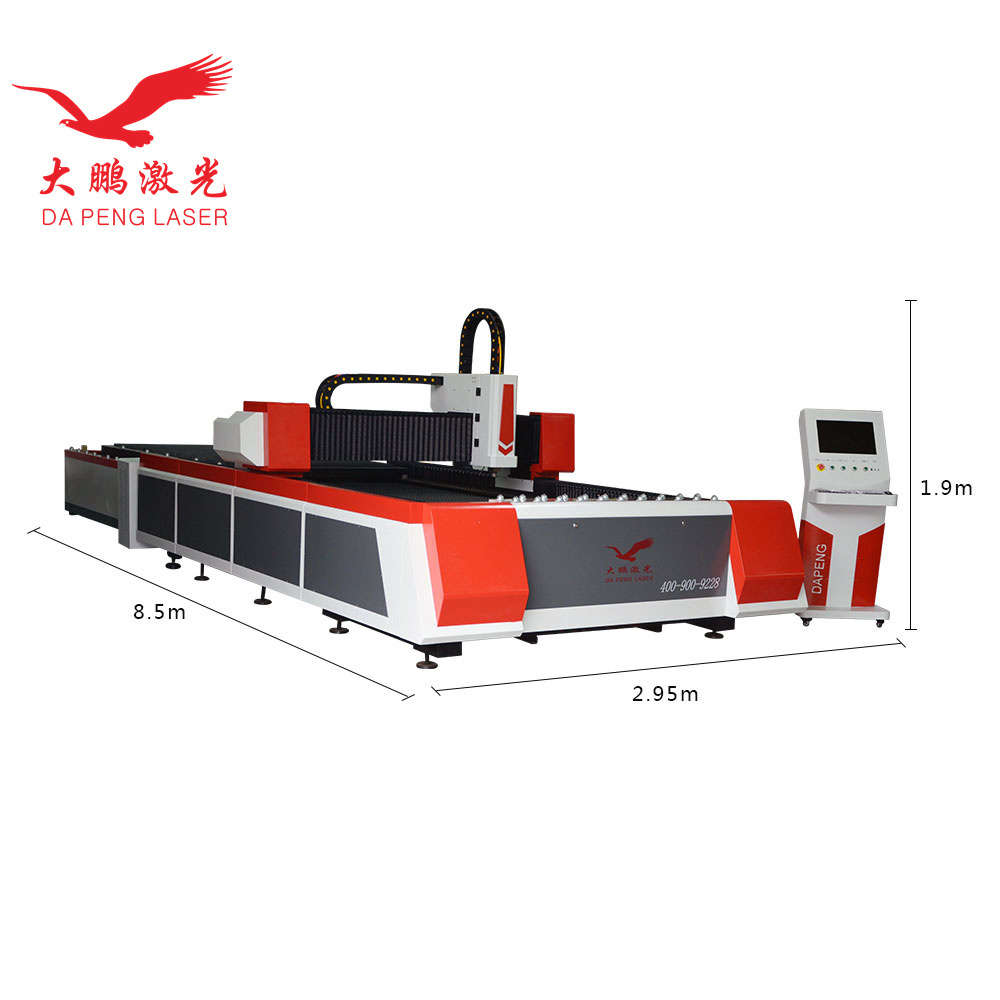

Product Description

Wholesale Price Single Bed 6020 1500W 2000W 3000W 6000W IPG Raycus nLGIHT Max Metal CNC Fiber Laser Cutter

Specification

|

Model

|

DPE-FT3015F-F1500W/F2000W/F3000W

|

|

Laser source type

|

Fiber source

|

|

Laser Out Power

|

1070nm

|

|

Laser wavelength

|

1000W/2000W/3000W

|

|

Cutting range

|

3000×1500mm

|

|

Minimum line width

|

<0.1mm

|

|

Transfer method

|

Precision rack dual drive

|

|

Cutting speed and thickness

|

Depending on specific material

|

|

Repeatability

|

±0.02mm

|

|

Machine operating temperature

|

0~40℃

|

|

Electricity demand

|

380V/50Hz

|

|

Cooling method

|

Water cooling

|

|

Continuous operating time

|

24 hours

|

|

Weight

|

5600KG

|

|

Dimensions

|

2100*2950*8500mm

|

|

Maximum operating speed

|

120m/min

|

|

Maximum acceleration

|

0.9G

|

|

X/Ypositioning accuracy

|

1.2mm

|

|

Minimum slit width

|

0.15mm

|

Features:

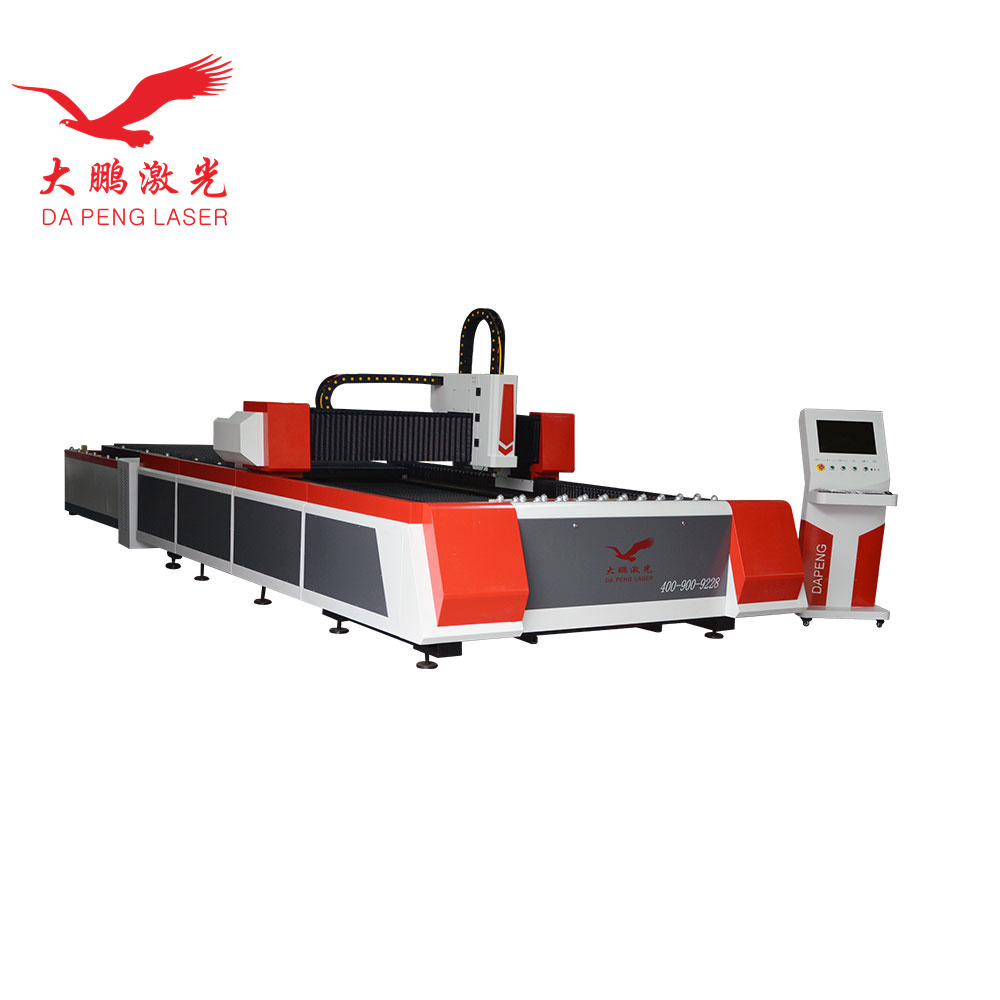

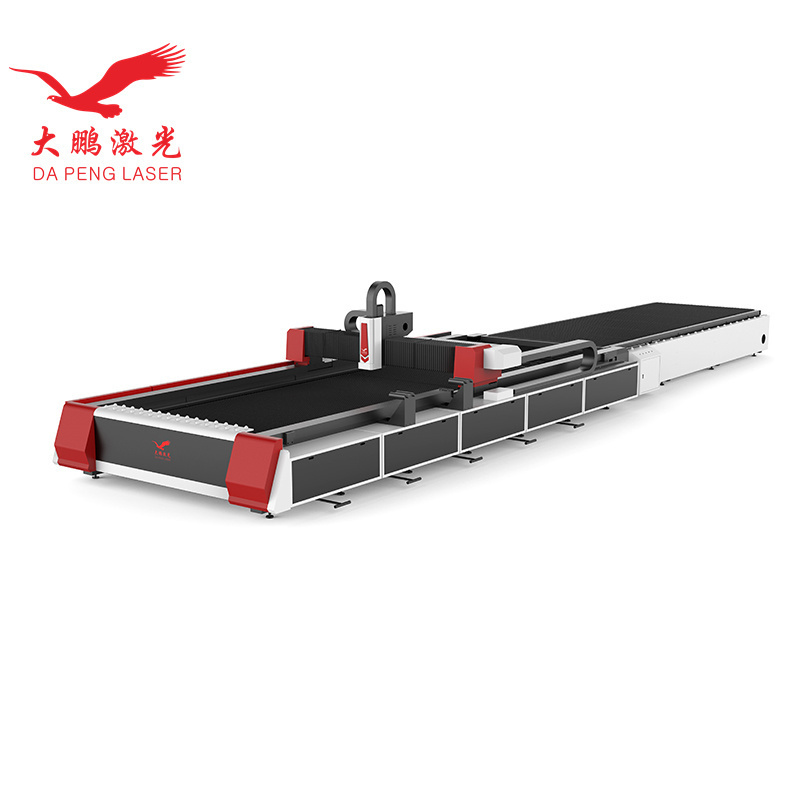

Exchange Platform Fiber Laser Cutting

1)Stable and reliable light path system and control system.

2)Double and exchange work platform save uploading time and cost.

3)Specialize in cutting metal plates, cost-saving.

4)New design for the whole machine with left and right funnels for waste collection space-saving.

5) Dual working table: one for cutting, one for feeding, which is easy for user to feeding and cutting in turns for continuous working, it greatly save time and enhance the working efficiency in mass production.

2)Double and exchange work platform save uploading time and cost.

3)Specialize in cutting metal plates, cost-saving.

4)New design for the whole machine with left and right funnels for waste collection space-saving.

5) Dual working table: one for cutting, one for feeding, which is easy for user to feeding and cutting in turns for continuous working, it greatly save time and enhance the working efficiency in mass production.

Widely used in automobiles, construction machinery, locomotives, agricultural and forestry machinery, electrical manufacturing, elevator manufacturing, household appliances, food machinery, textile machinery, tool processing, petroleum machinery, food machinery, kitchen and kitchenware, decorative advertisements, laser external processing services, etc. Machinery manufacturing and processing industry.

· High-performance optical fiber transmission, flexible processing, can realize high-quality cutting of any shape, and is suitable for cutting high reflective materials such as copper and aluminum;

· High efficiency, fast cutting speed, low operating cost, double return on your investment;

· Low gas consumption, laser generation requires no gas generation;

· Low energy consumption, energy saving and environmental protection, low power consumption;

· Low maintenance, no reflection lens, no need to adjust the light path, basic maintenance-free;

·A machine can be used for both cutting plates, but also cutting pipes, efficient processing machines.

>> Features Fiber laser cutting machine for metal:

1. Laser

Adopting the world’s top fiber laser, stable performance, high efficiency and low cost.

2. Mechanical structure

With double drive closed-loop structure displacement, Y direction has a strong driving force and high speed, which can give full play to the high speed characteristics of fiber laser.After two times of aging treatment, the structure of bed body is strengthened to ensure the stability and precision of bed body for a long time.

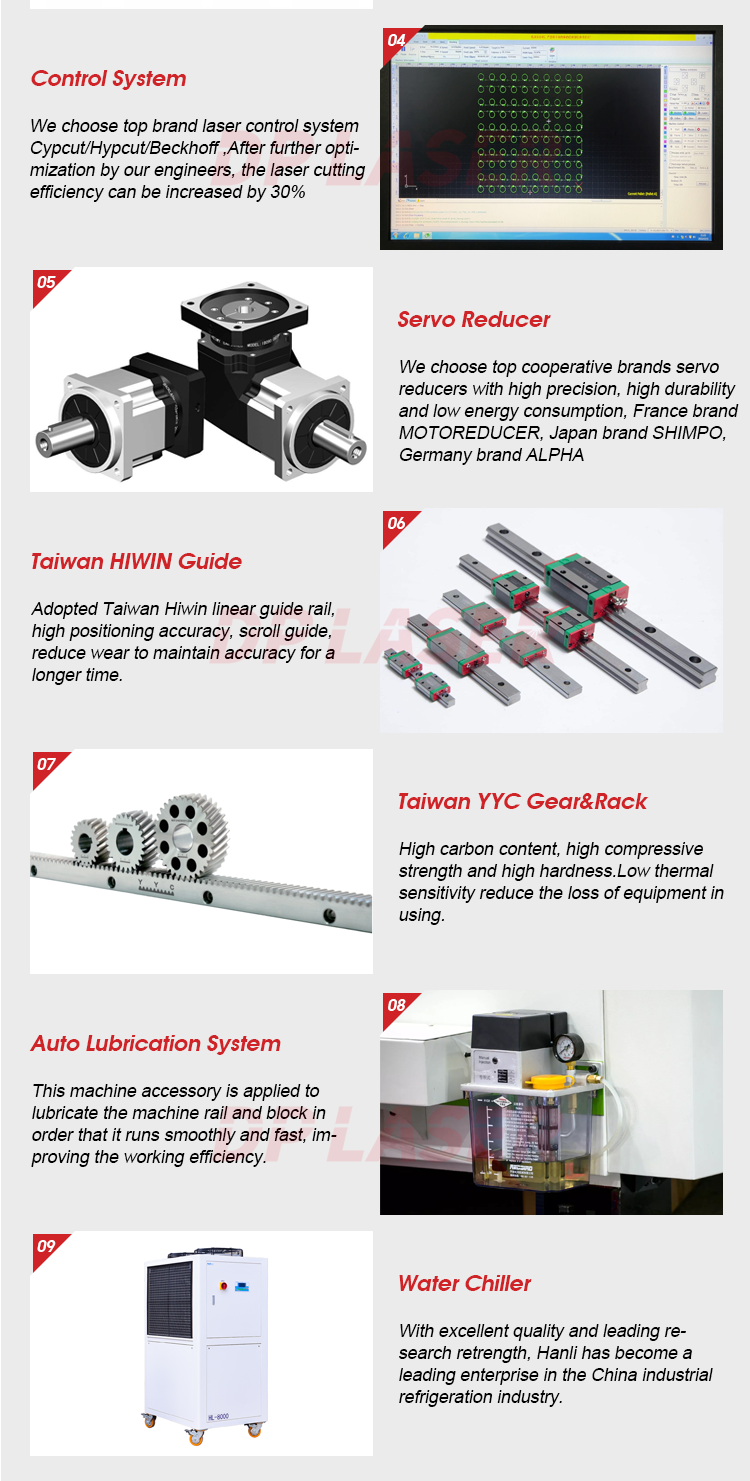

3. Control system

By using open CNC system provided by the top suppliers and integrating the company experience in laser industry for many years, the man-machine interface is so simple and more convenient to operate.

4. Follow-up cutting head

By using the follow-up cutting head of international famous brand, the laser is always in the focus position, can ensure the cutting effect.

5. Metal nesting software

The optimized software algorithm can save the material to the maximum extent. Integrated a variety of specialty metal cutting technology such as common edge,bridge and micro connection,the difficulty of operation is reduced, so that improves the material management function, make full use of waste materials and meet the management needs.

6. Auxiliary air blowing system

System combines high and low voltage conversion gas path and three gas source structure composed of high pressure air, nitrogen and oxygen, so customers can select the auxiliary gas according to the processing quality requirements and cost.

7. Lubrication system

The whole machine is equipped with lubrication system, which reduces the wear of moving parts and ensures the movement speed of the whole machine.

8. Editing system

The software supports the input and output of the general CAD format file (PLT, DXF, DST, AI, BMP, etc), as well as graphics editor (zoom, rotate, array, etc)function.

Application Materials:

Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless

Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate,

Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold

Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Application Industries:

Fiber Laser Cutting Machines are widely used in manufacturing

Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters,

Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing,

Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic

Parts, Nameplates, etc.

Click here to contact us for more information

Hot Searches