- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Soft or hard leather

-

Color:

-

Red

-

Feed Speed:

-

Stepless Speed Change

-

Working Width:

-

420mm

-

With Knife Specifications:

-

3750*60*0.8mm

-

Max Split Thickness:

-

8mm

-

G.W.:

-

790kg

-

N.W.:

-

740kg

Quick Details

-

Voltage:

-

380v

-

Place of Origin:

-

Guangdong, China

-

Name:

-

Leather Splitting Machine Supplier Leather Sole Splitting Machine

-

Application:

-

Soft or hard leather

-

Color:

-

Red

-

Feed Speed:

-

Stepless Speed Change

-

Working Width:

-

420mm

-

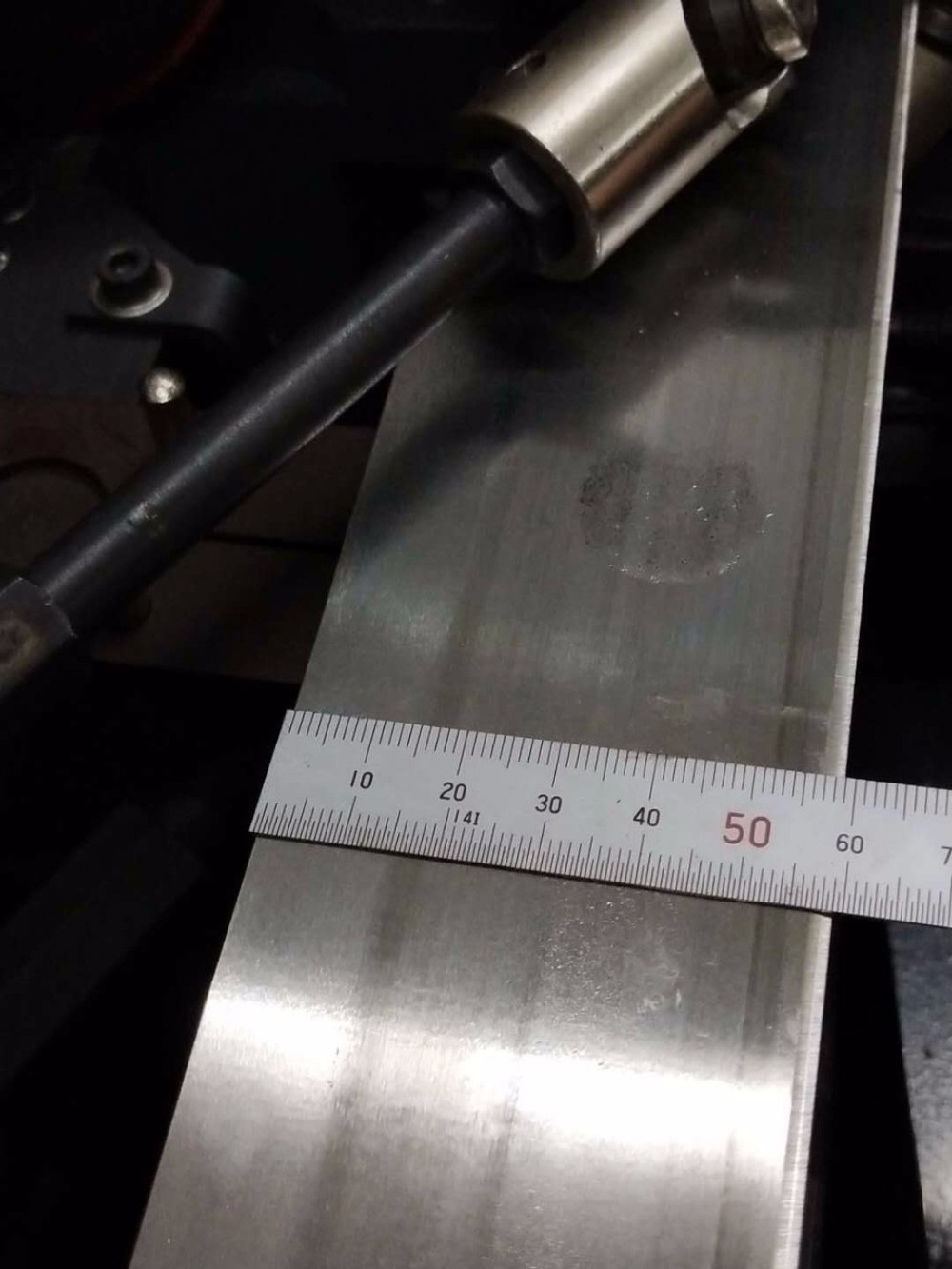

With Knife Specifications:

-

3750*60*0.8mm

-

Max Split Thickness:

-

8mm

-

G.W.:

-

790kg

-

N.W.:

-

740kg

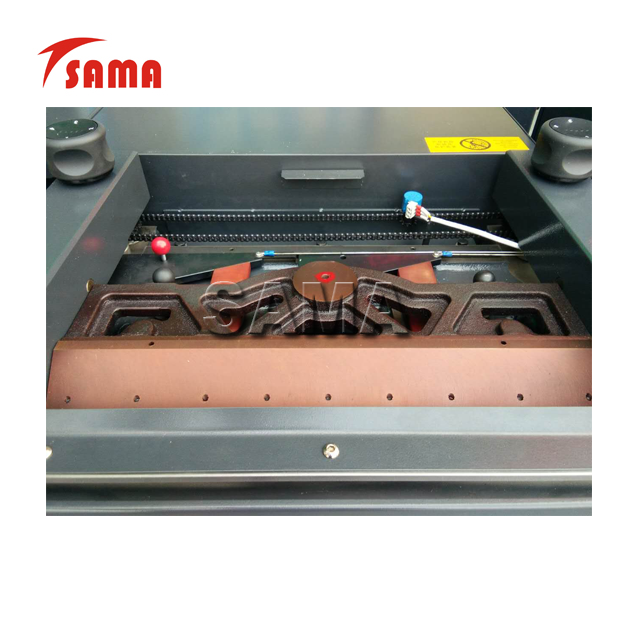

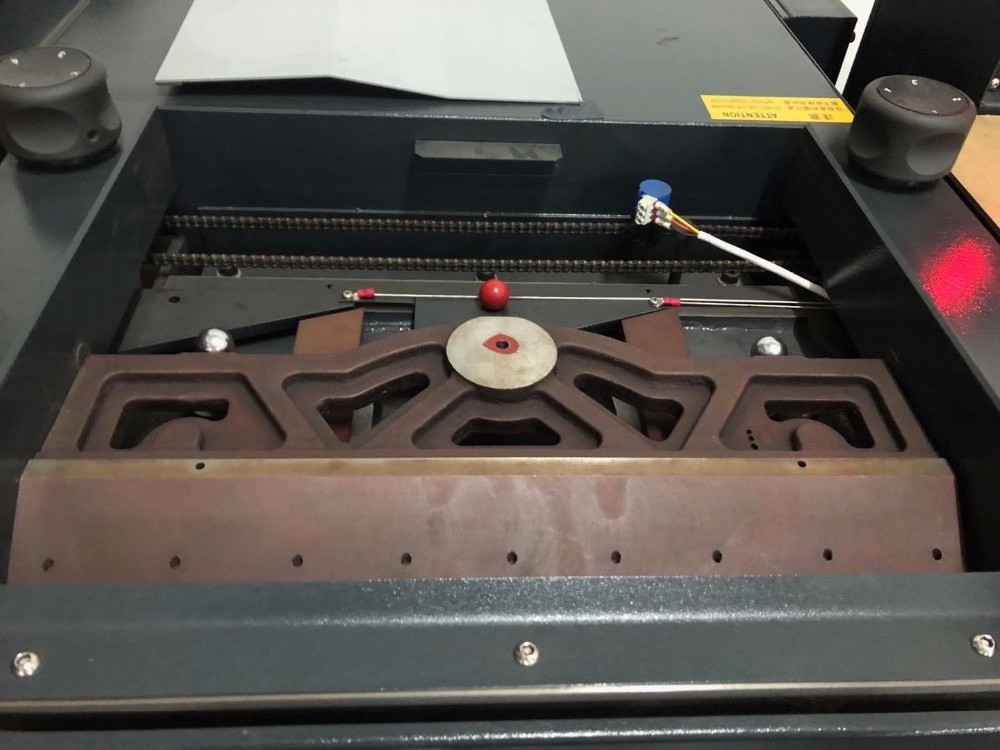

S420RC+ Leather Splitting Machine Supplier Leather Sole Splitting Machine

The machine adapts to splitting the hard or soft leather symmetrically, which the width is less than 420mm and the thickness is less than 8mm. According the required thickness in the industry of leather products, improve the quality of products and strengthen the competitiveness of markets.

Features

- Knife bandwidth 60mm, longer life, more stable machine.

- Clamping device adopts honeycomb design, more easy to heat, suitable for use in tropical areas.

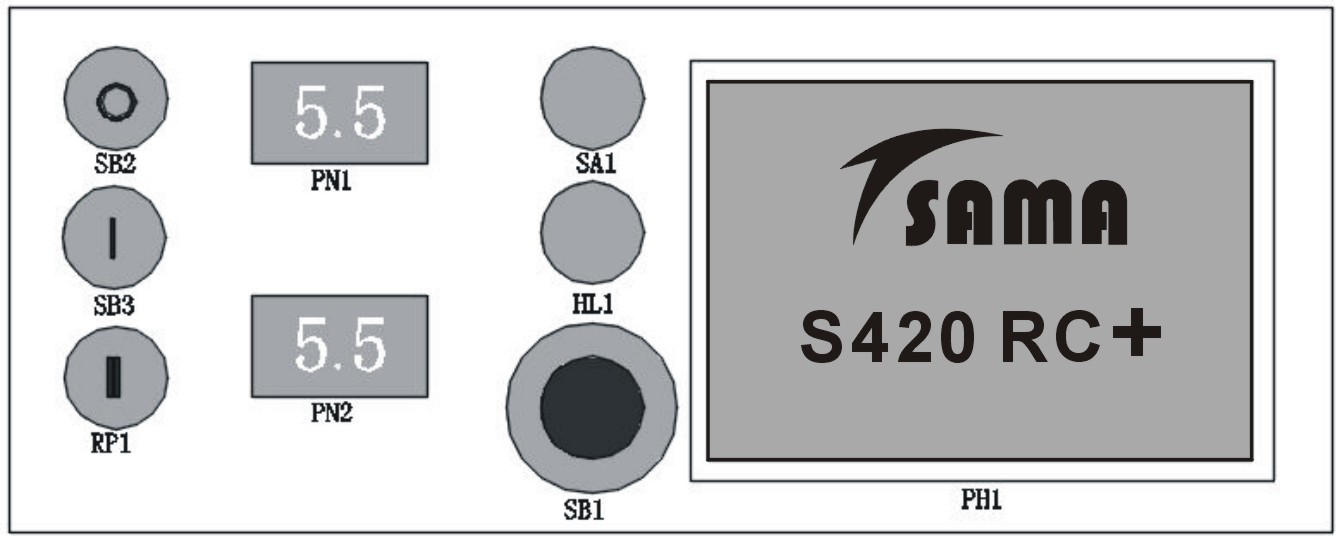

- Split thickness and feed speed are digital display, more convenient and intuitive.

- There are more than 10 pictures showing machine failure, alarm and prompt, more convenient operation and troubleshooting.

- Additional counting function, always grasp the output.

- The newly designed special dust collector makes the dust cleaner effect better.

Technical Parameter

|

Model |

S420RC+ |

|

Feeding speed |

Stepless speed change |

|

Fault display |

Touch Screen |

| Indicator & Information | Touch Screen |

|

Working pressure |

Mechanics |

|

Installation power |

3.6kw |

|

Working Width |

420mm |

|

Max.splitting thickness |

8mm |

|

Min.splitting thickness |

0.5mm with top feed roll |

| 0.1mm with top bar | |

|

Knife dimensions |

3750×60×0.8mm |

| Machine size(L×W×H) | 1700×1100×1290mm |

| Package size(L×W×H) | 1750×1150×1440mm |

| N.W. | 740KG |

|

G.W. |

790KG |

Advantages

Our machines are studied and manufactured accordingly to three basic principles:

1.Quality and Accuracy Accuracy of the materials used and of the production process undertaken in the manufacturing of each single components in order to guarantee excellence in performances;

2.Ergonomics and Flexibility in operating and maintaining our machines in order to increase productivity, limit idle time and reduce operational costs (such as less working stress for operators, reduced machine stops for maintenance and band knife substitution, fast switching settings…);

3.Reliability and Solidity of single components and complete machines in order to provide our customers with top performances stable over decades (proved by the thousands of machines still perfectly working even after 25-30 years)

The constant search for improvements through technical innovations (with several deposited patents) along with a special attention to the smallest details are the “secrets” of our achievements …

| Item | Name of machine or parts | Specification | Amount |

| 1 | S420RC+ Splitting Machine | set | 1 |

| 2 | The machine tools | set | 1 |

| 3 | Band knife lubes | pc | 1 |

| 4 | Thickness gauge | pc | 1 |

| 5 | Granding knife sharpening belt | pc | 1 |

| 6 | Wool Felt | pc | 1 |

| 7 | Fuse wire | pc | 3 |

| 8 | Instruction Manual | pc | 1 |