- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15kw

-

Dimension(L*W*H):

-

1.68x1.5x2.1

-

Weight (KG):

-

680

-

Product name:

-

Industrial Pilot High Speed Centrifugal Lab Spray Drying Machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Use:

-

Lab or pilot

-

Atomizer:

-

Centrifugal atomizer

-

Heater:

-

Electric heater

-

Water consumption:

-

0.1m3/h

-

Evaporation:

-

3~5Kg/h

-

Inlet operation temperature:

-

180-250 ℃

-

Spare parts:

-

supply the whole lifetime

Quick Details

-

Type:

-

Spray Drying Equipment

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

220V - 450V

-

Power:

-

15kw

-

Dimension(L*W*H):

-

1.68x1.5x2.1

-

Weight (KG):

-

680

-

Product name:

-

Industrial Pilot High Speed Centrifugal Lab Spray Drying Machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Use:

-

Lab or pilot

-

Atomizer:

-

Centrifugal atomizer

-

Heater:

-

Electric heater

-

Water consumption:

-

0.1m3/h

-

Evaporation:

-

3~5Kg/h

-

Inlet operation temperature:

-

180-250 ℃

-

Spare parts:

-

supply the whole lifetime

Product Description

Performance Characteristics

1. The drying speed is fast, and the surface area of the material liquid greatly increases after

atomization. In the hot air flow, 95% -98% of the water can be instantly evaporated, and the drying time is only a few

seconds. It is particularly suitable for drying heat-sensitive materials.

atomization. In the hot air flow, 95% -98% of the water can be instantly evaporated, and the drying time is only a few

seconds. It is particularly suitable for drying heat-sensitive materials.

2. The product has good uniformity, fluidity, and solubility, high purity, and good quality.

3. Simplify the production process and facilitate operation and control. For liquids with a moisture content of 40-60% (up to 90% for special materials), they can be dried into powder products in one go, without the need for crushing and screening after drying, reducing production processes and improving product purity. The particle size, bulk density, and moisture of the product can be adjusted within a certain range by changing the operating conditions, making it easy to control and manage.

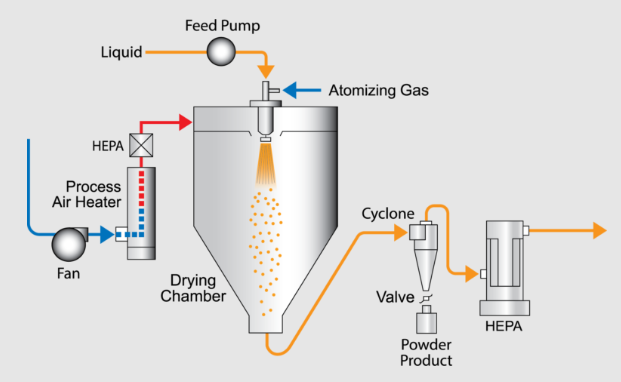

Working Principle

The air enters the air distributor at the top of the centrifugal spray dryer through the filter and heater, and the hot air enters the dryer evenly in a spiral shape. The material liquid is pumped from the material liquid tank through a filter to the centrifugal atomizer at the top of the dryer, causing the material liquid to spray into extremely small mist like droplets. The material liquid and hot air come into contact, and the moisture evaporates rapidly. The finished product is dried in a very short time, and the finished product is discharged from the bottom of the drying tower and the cyclone separator. The exhaust gas is discharged by the fan.

|

Model

|

LPG-5

|

LPG-25

|

LPG-50

|

LPG-100

|

LPG-150

|

LPG-

200-2000

|

|||||

|

Inlet temperature

|

140-350℃

|

|

|

|

|

|

|||||

|

Outlet temperature

|

80-90℃

|

|

|

|

|

|

|||||

|

Max Evaporate capacity (kg/h)

|

5

|

25

|

50

|

100

|

150

|

200-2000

|

|||||

|

Centrifugal spray drive type

|

Compressed air drive

|

Mechanical drive

|

|

|

|

|

|||||

|

Max Rotary speed

|

25000

|

18000

|

18000

|

15000

|

15000

|

8000-15000

|

|||||

|

Spray tray diameter(mm)

|

50

|

120

|

120

|

150

|

150

|

180-300

|

|||||

|

Heating source

|

Electricity

|

Electricity/LPG/Natural gas/Oil/Steam

|

|

|

|

|

|||||

|

Heating power (kw)

|

9

|

36

|

48

|

72

|

84

|

/

|

|||||

|

Dry powder yield (%)

|

≥95

|

|

|

|

|

|

|||||

Hot Searches