- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

3-phase 4-wires, 380V, 50Hz, customized

-

Dimension(L*W*H):

-

900mm*900mm*1550mm

-

Weight (KG):

-

150 KG

-

After-sales Service Provided:

-

Overseas third-party support available

-

Product Name:

-

Manufacturer Price High pressure polyurethane injection foam machine

-

Material:

-

polyol and ISO

-

Application:

-

Spray Wall or others

-

Item:

-

two components electric spray equipment JHPK-DD3

-

Driven way for injection gun:

-

Hydraulic Driven

-

Injection gun cleaning way:

-

Mechanical cleaning

-

Power source:

-

3-phase 4-wires, 380V, 50Hz, or it can be customized

-

Hydraulic working pressure:

-

8~12 Mpa(1160~1740psi)

-

Power(W):

-

2000W*2

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

JHPK

-

Machine Type:

-

FOAM

-

Voltage:

-

3-phase 4-wires, 380V, 50Hz, customized

-

Dimension(L*W*H):

-

900mm*900mm*1550mm

-

Weight (KG):

-

150 KG

-

After-sales Service Provided:

-

Overseas third-party support available

-

Product Name:

-

Manufacturer Price High pressure polyurethane injection foam machine

-

Material:

-

polyol and ISO

-

Application:

-

Spray Wall or others

-

Item:

-

two components electric spray equipment JHPK-DD3

-

Driven way for injection gun:

-

Hydraulic Driven

-

Injection gun cleaning way:

-

Mechanical cleaning

-

Power source:

-

3-phase 4-wires, 380V, 50Hz, or it can be customized

-

Hydraulic working pressure:

-

8~12 Mpa(1160~1740psi)

-

Power(W):

-

2000W*2

Description

Description

Our company has obtained Quality Management System Certificates ISO9000. The advanced management system and high efficient and modern production mode provide reliable quality assurance for our products.

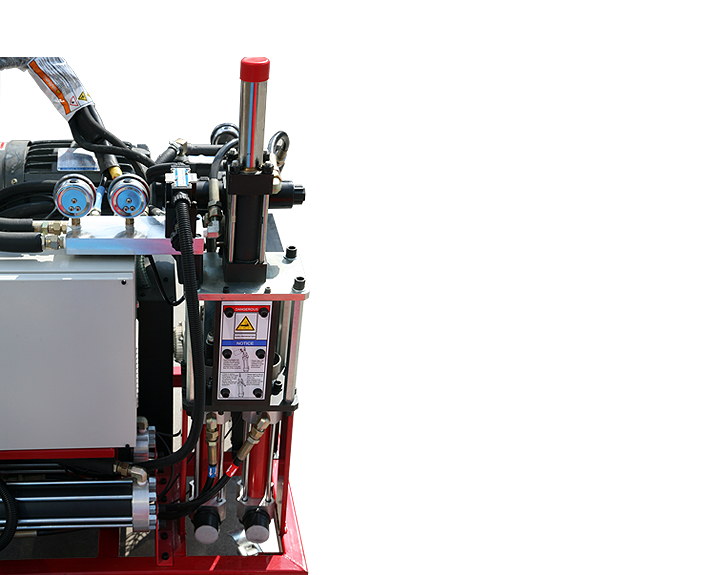

JHPK-YGAF,a high-pressure polyurethane foaming equipment. It is hydraulic-driven and high-pressure polyurethane foaming equipment after the JHPK-YGAF hydraulic polyurethane foaming equipment by Beijing Jinghua Park Polyurethane Equipment Co.Ltd.

The system of this machinery not only keeps the advanced technology of SBP so keeps the pressure of the row materials liquid steadily and mixes the double component materials more evenly, but also has the advanced device of hydraulic station air-cooled unit,reducing the maximum using of oil for the machine and cutting down the maintenance fee of the hydraulic system. Tight, optimal, simple and direct instruction of perfusion gun makes the machine working firmly. Strong working power has solved the jam issue of the spray gun, which has puzzled the small type of foaming equipment for a long time.

Main parts of the machine have been imported from abroad to make sure the machine works superiorly. Extremely reliable operating mechanism is easy to install, and maintain.

It is the most advanced and durable high-pressure polyurethane perfusion foaming equipment in china, which can bring you a lot of advantages.

Standard Configuration:

| Main equipment | 1 set |

| injection gun | 1 piece |

| Heating pipe | 8 m |

| Spare parts | 1 set |

| Tools | 1 set |

| English manual | 1 set |

| Package | plywood tray |

Technical Parameter:

| Ratio of raw materials | 1:1 |

| Viscosity range | 200~1000CPS |

| Output of raw materials | 4~8L/ min |

| Heating power | 2000W*2 |

| Heating temperature range | 5~10 Mpa(725~1450PSI) |

| Gun cleaning way | 0℃~60℃ |

| Maximum hydraulic driven power | 21Mpa(3045psi) |

| Hydraulic working pressure | 8~12 Mpa(1160~1740psi) |

| Power source | 3-phase 4-wires, 380V, 50Hz, or it can be customized |

| Injection gun cleaning way | Mechanical cleaning |

| Driven way for booster pumps | Hydraulic Driven |

| Driven way for injection gun | Hydraulic Driven |

Q: Are You the factory or trade company?

A:We are the factory,found in 2003 , we have work ed on alibaba export for 7 years.

Q: what’s the machine voltage?can it suitable for my local place?

A: the Standard machine is 3 phase ,380V,50HZ .We can change the electrical wire for your local place.

Q:D o you have any training videos on how to operate and maintain the machine ?

A: We offer Free video training and maintenance .

24 hours online sevices (Skype, WhatsApp, WeChat, Telphone) .

If you come to China, We have two days free training in the factory .

Engineers on-site service (some countries and regions) ,but the fee is charged.

Q: What’s the warranty period ?

A: our machine warranty period is 1 2 month, and support lifelong consultant service.

Q: What’ s the delivery time?

A:

Generally speaking ,we can send the machines 2~3 days after we get the payment if you don’t need to change the wire.Pls ask the salesmans about the details.

Q:What’s the shpping way?How to get the spare parts if the machines are broken?

A:We can send the machines by sea,by air or by railway.It depends on your choose.

W e can send the spare parts through DHL ,FedEx,UPS,TNT internation Express,very fast.