- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

PRESNDFEBM

-

Product Name:

-

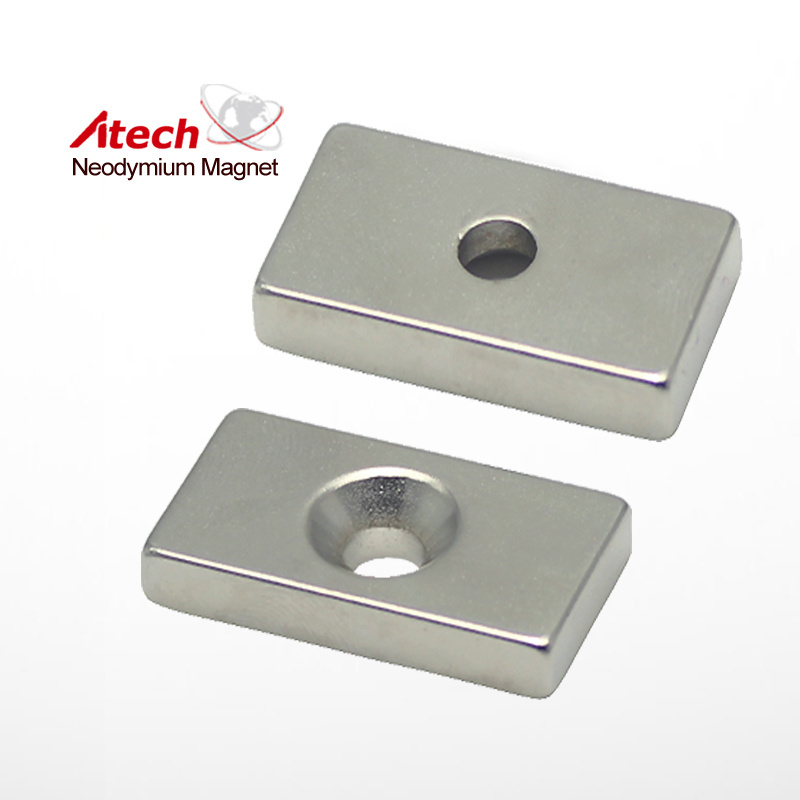

Rectangular Pot Magnets 4mm Thick With Counter Bore Hollow

-

Technique:

-

Sintering Block Neodymium Magnets

-

Grade:

-

N35-N52,33M-50M,30H-48H,30SH-45SH,28UH-40UH,28EH-38EH and 28AH-33AH

-

Size:

-

Customized Block Neodymium Magnets

-

Surface Treatment:

-

Ni,Ni-Cu-Ni,Zn,silver,gold,aluminum,epoxy,phosphating and etc.

-

Description:

-

Largest Block Neodymium Magnets

-

Material:

-

Sintered Block Neodymium Magnets

-

Magnetism direction:

-

Thickness Block Neodymium Magnets

-

Certification:

-

ISO9001:2000 Block Neodymium Magnets

Quick Details

-

Tolerance:

-

±5%

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

ATECH

-

Model Number:

-

PRESNDFEBM

-

Product Name:

-

Rectangular Pot Magnets 4mm Thick With Counter Bore Hollow

-

Technique:

-

Sintering Block Neodymium Magnets

-

Grade:

-

N35-N52,33M-50M,30H-48H,30SH-45SH,28UH-40UH,28EH-38EH and 28AH-33AH

-

Size:

-

Customized Block Neodymium Magnets

-

Surface Treatment:

-

Ni,Ni-Cu-Ni,Zn,silver,gold,aluminum,epoxy,phosphating and etc.

-

Description:

-

Largest Block Neodymium Magnets

-

Material:

-

Sintered Block Neodymium Magnets

-

Magnetism direction:

-

Thickness Block Neodymium Magnets

-

Certification:

-

ISO9001:2000 Block Neodymium Magnets

DNA Of NdFeB Magnets

| Material | Sintered Neodymium Iron Boron | |

| Working Temperature | Grade | Max. Workinging Temperatures |

| N35-N52 | 80°C (176°F) | |

| 33M- 48M | 100°C (212°F) | |

| 33H-48H | 120°C (248°F) | |

|

30SH-45SH |

150°C (302°F) | |

| 30UH-40UH | 180°C (356°F) | |

| 28EH-38EH | 200°C (392°F) | |

| 28AH-35AH | 230°C (428°F) | |

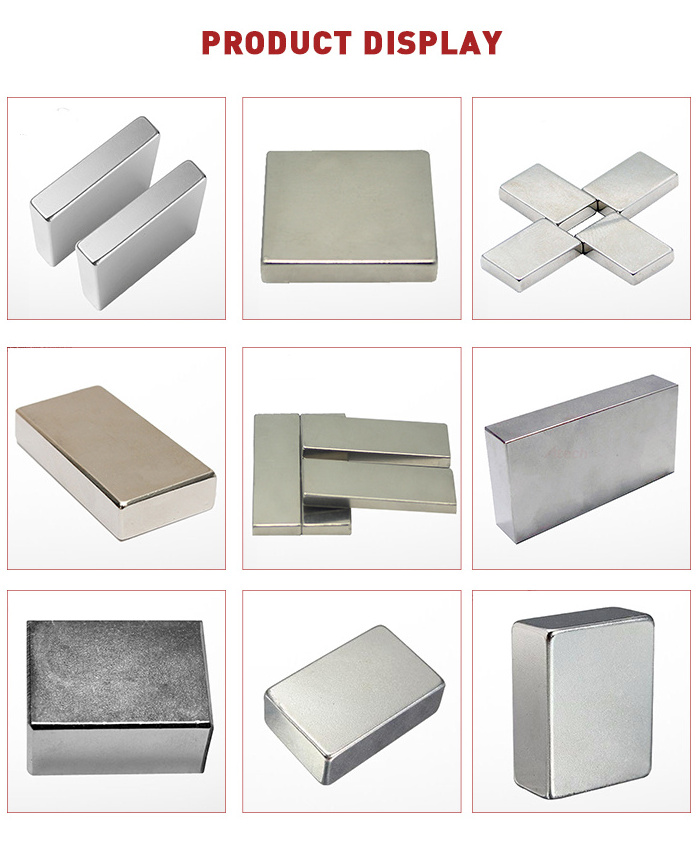

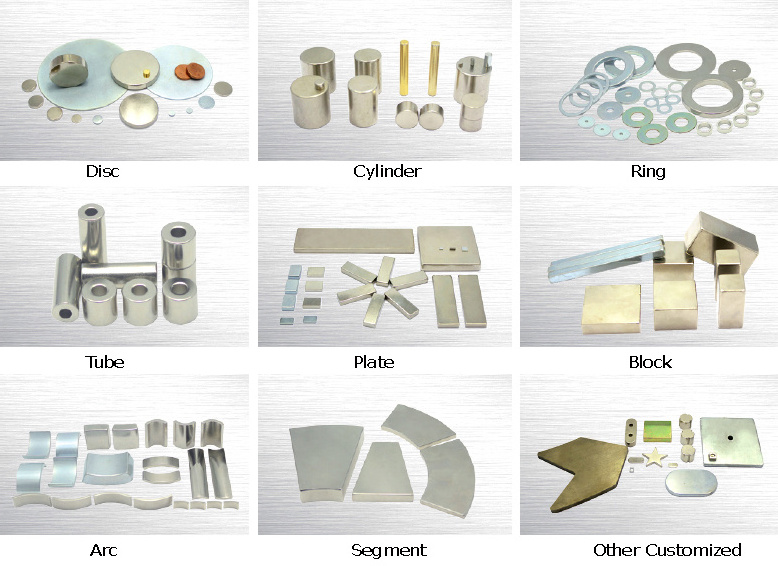

| Magnet Shapes | Disc, Cylinder, Block, Ring, Countersunk, Segment, Trapezoid, Irregular shapes and more. The shapes can be customized. | |

| Magnet Coatings | Ni-Cu-Ni, Nickel, Zn, Gold, Silver, Copper, Epoxy, Chemical, PTFE, Parylene, Everlube, Passivation and more. | |

| Technology Advantage | Depending on advanced R&D center, Quality control team and professional machining technicians, we can surpass our competitors in the stability of quality and superiority of property. | |

| Tolerance | Standard tolerance, usually +/-0.05mm. | |

Atech Neodymium Permanent Magnet (also known as NdFeB, NIB or Neo magnet ), the most widely used type of rare-earth magnet, is a permanent magnet made from an alloy of neodymium, iron and boron to form the Nd2Fe14B tetragonal crystalline structure.Multiple choices of shapes can meet specific customer requirements.

Features

Well known as "The Lord of Magnet", the tetragonal Nd2Fe14B crystal structure has exceptionally high uniaxial magnetocrystalline anisotropy (HA ~7 T – magnetic field strength H in units of A/m versus magnetic moment in A·m2). This means a crystal of the material preferentially magnetizes along a specific crystal axis, but is very difficult to magnetize in other directions. The resistance of the crystal lattice to turning its direction of magnetization gives the compound a very high coercivity, or resistance to being demagnetized.

Grades

The Grade of a magnet generally indicates how “strong” a magnet material is, which is measured by the Maximum Energy Product. The energy product is commonly specified in units of Gauss Oersted. The higher the grade the “stronger” the magnet.

Atech Neodymium Permanent Magnet are graded according to their maximum energy product, which relates to the magnetic flux output per unit volume. Higher values indicate stronger magnets and range from N35 up to N52. and M, H, SH, UH, EH, AH series,can be customized into a wide range of shapes and sizes with precise tolerances. Multiple choices of coatings and magnetization orientations can meet specific customer requirements. Letters following the grade indicate maximum operating temperatures (often the Curie temperature), which range from M (up to 100 °C) to EH (200 °C) to AH (230 °C)

Coatings

As Neodymium magnet is prone to corrosion, it is usually preferable to be coated for protection. Among a variety of options for coatings, nickel and nickel-copper-nickel are the most commonly used, making the magnet more corrosion resistant and durable.

Our magnet products can be delivered magnetized and un-magnetized. Some production methods require the magnets being incorporated into assemblies in a un-magnetized state and magnetized later once the assembly is completed. There are various magnetic orientations available for different shapes of magnets.

Technical Data

Our company is committed to the research and development of good performance NdFeB magnets. Our product range covers all grades listed in the following performance table, and we are better at (following up the requirements of customers) the adjustment of formula and the pursuit of the top valued magnetic products..

Notes:

1. The above mentioned data of magnetic parameters and physical properties are given at room temperature of 20℃±2.

2. The maximum service temperature of magnet is changeable due to the ratio of length and diameter, coating and environmental factors.

Packing specification

The magnet is packed in high quality plastic bags, Protective foam boxes, cartons and wooden pallets are used to ensure that every package is firm and secure and the products are very well protected. For air shipment, iron sheets and bubble packs are also used to shield magnetized magnets so that external effects of magnetic fields can be minimized to meet the requirements of aviation safety.

Caution

Neodymium magnets ( Nd2Fe14B Magent ) can be dangerous, as they generate extremely strong pull forces, therefore must be handled with care to avoid personal injury and damage to the magnets. Fingers and other body parts can get severely pinched between two attracting magnets. Neodymium magnets are brittle, and can shatter if allowed to slam together, launching small pieces at great speeds. Eye protection should be worn when handling there magnets.

The strong magnetic fields of neodymium magnets can also damage electronic appliances and magnetic media, as well as affect the operation of medical devices. Never place neodymium magnets near television, VCRs, computers, credit cards, magnetic I.D.cards, video tapes, pacemakers and etc.