Output 1 4000kva black silicon carbide smelting furnace.There are two processing lines for segment sand and silicon carbide fine

powder, and two production lines for No. 1 sand. The total annual production of black silicon carbide is more than 80000 tons, and

the deep processing of black silicon carbide of various specifications is about 100000 tons.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yafit

-

Model Number:

-

0-3mm

-

Usage:

-

Abrasive and Refractoy, Refractoy

-

Product name:

-

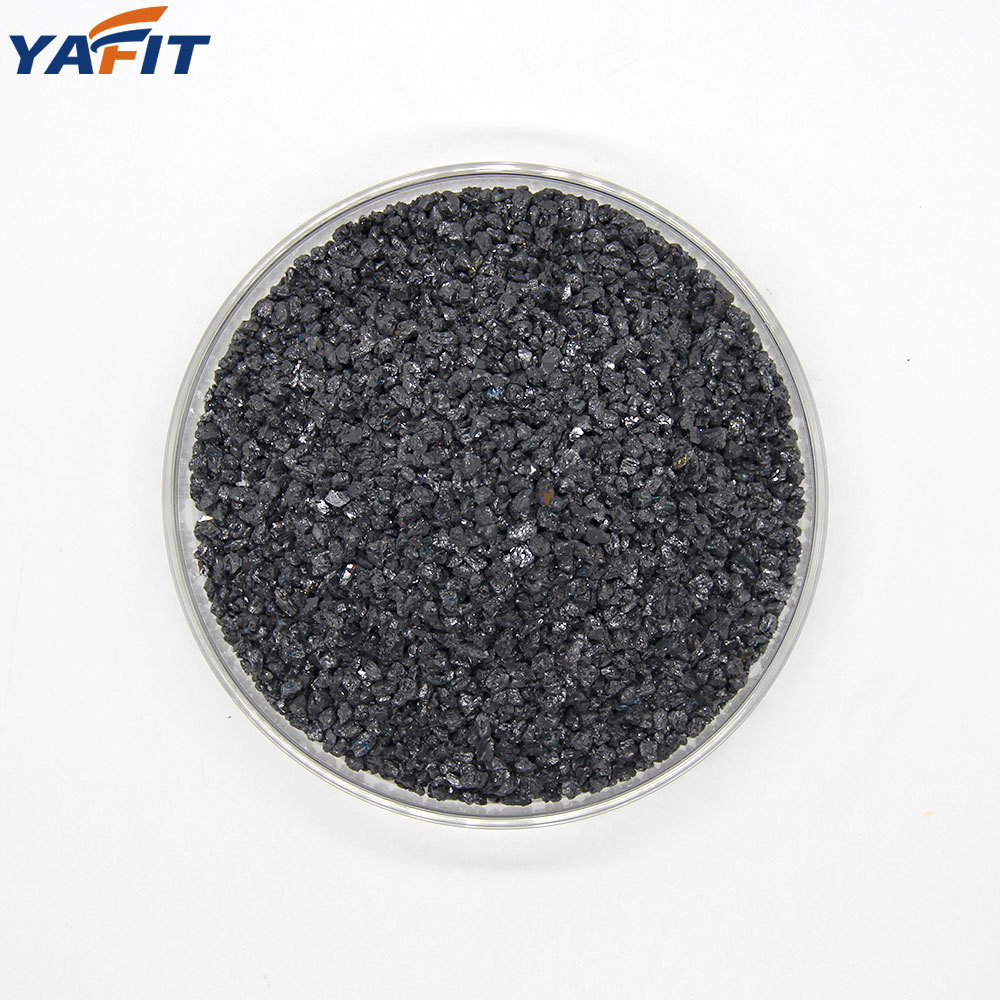

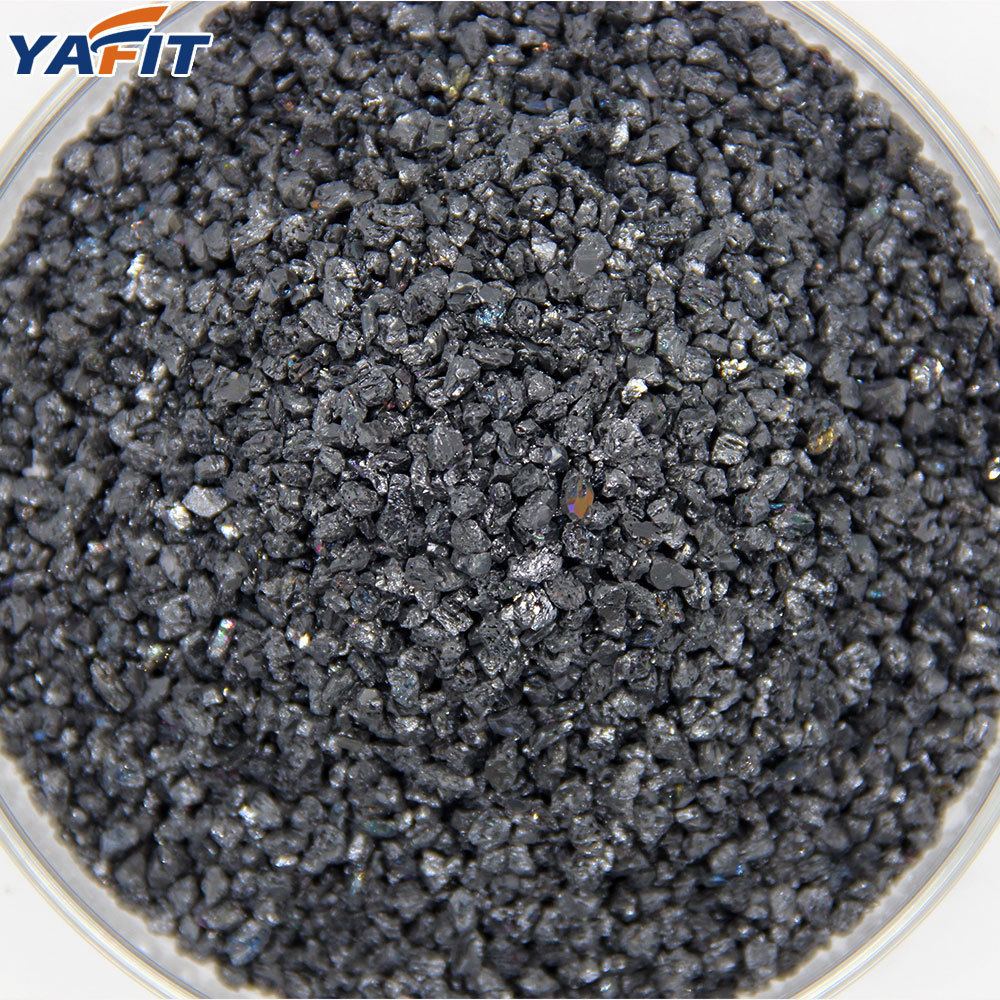

Black Silicon Carbide

-

Advantage:

-

High Pressure Resistance

-

Material:

-

Silicon Carbide Sic

-

Feature:

-

High Purity

-

Size:

-

0-3mm

-

Color:

-

Black

-

Purity:

-

98%

-

Package:

-

25kg/bag

Quick Details

-

Type:

-

blasting media

-

Abrasive Grain Sizes:

-

0-3mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yafit

-

Model Number:

-

0-3mm

-

Usage:

-

Abrasive and Refractoy, Refractoy

-

Product name:

-

Black Silicon Carbide

-

Advantage:

-

High Pressure Resistance

-

Material:

-

Silicon Carbide Sic

-

Feature:

-

High Purity

-

Size:

-

0-3mm

-

Color:

-

Black

-

Purity:

-

98%

-

Package:

-

25kg/bag

Products Description

BLACK SILICON CARBIDE

Black Silicon Carbide (SiC) is an extremely hard (Mohs 9.1/ 2550 Knoop) man made mineral that possesses high thermal conductivity and high strength at elevated temperatures (at 1000°C, SiC is 7.5 times stronger than Al203 ). SiC has a modulus of elasticity of 410 GPa, with no decrease in strength up to 1600°C, and it does not melt at normal pressures but instead dissociates at 2600°C.

Product Paramenters

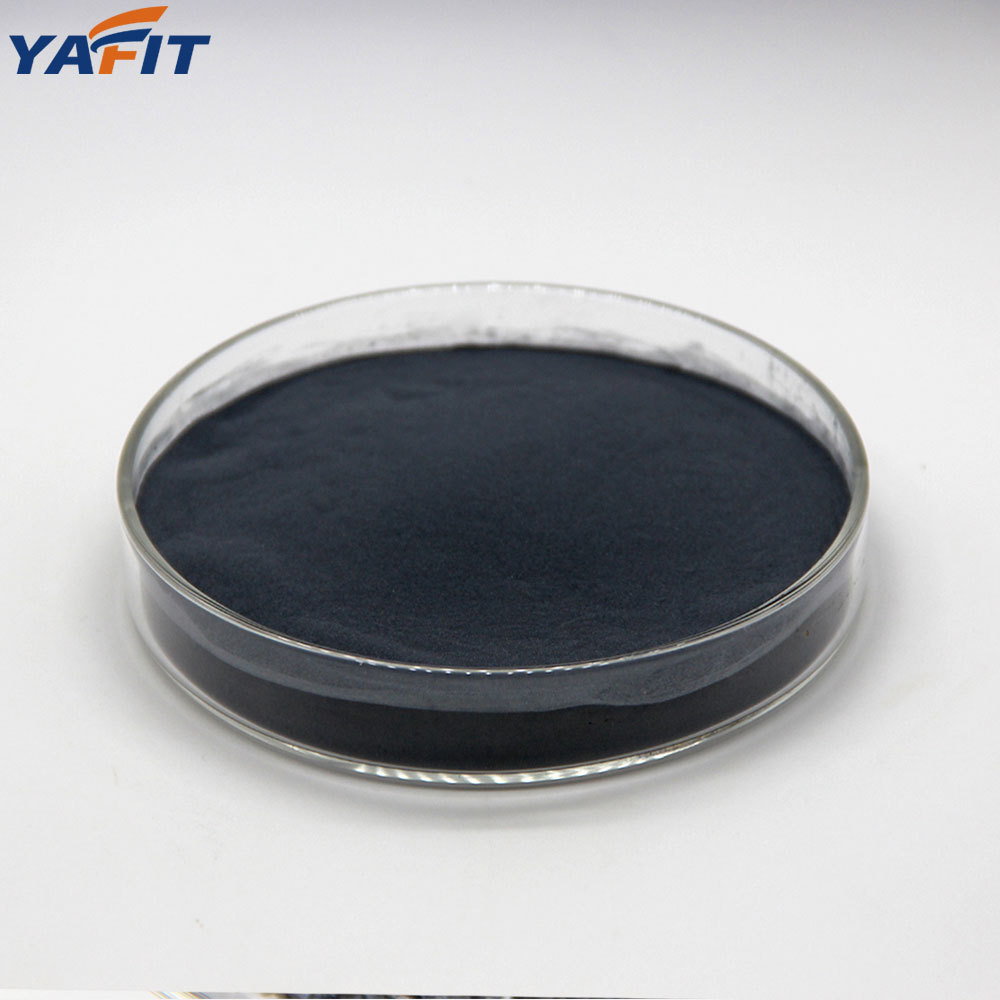

A: Micropowder Black Silicon Carbide

|

Product Name

|

Size

|

Color

|

Purity

|

||

|

|

1-0mm

|

|

>98%

>95%

>90%

>85%

|

||

|

|

3-1mm

|

Black

|

>

|

||

|

|

5-3mm

|

|

>

|

||

|

|

200F

|

|

>

|

||

|

|

325F

|

|

>

|

||

|

Application

|

Emery; refractory sand; Carborundum; High temperature resistant materials

|

|

|

||

B: Refractory Black Silicon Carbide

|

Micropowder

|

W Standard

|

W63# 、W50#、W40#、W28#、W20#、W14#、W10#、W7#、

W5#、W3.5#、W2.5#、W1.5#

|

|

|

|

FEPA Standard

|

F230#、F240#、 F280# 、F320#、 F360#、 F400#、F500#、 F600#、

F800#、F1000#、F1200#、F1500#、F2000#

|

|

|

|

JIS Standard

|

JIS240#、JIS280#、JIS320#、 JIS360#、 JIS400#、JIS500#、

JIS600#、 JIS700#、JIS800# 、IS1000#、JIS1200#、JIS1500#、

JIS2000#、JIS2500#、JIS3000#、 JIS4000#、 JIS6000#、IS8000#、

JIS10000#

|

|

|

Application

|

• high-temperature ceramics

• recrystallized silicon carbide.

• high-purity single crystals and semiconductors

|

|

|

C: Grains Black Silicon Carbide

|

|

F Series

|

F16、F20、 F22、F24、 F30、 F36、F40, F46、F54, F60, F70, F80, F90、F100、 F120、 F150, F180, F220, F240

|

|

|

|

P Series

|

P16, P20, P22, P24、 P30, P36, P40, P46P54, P60, P70, P80,P90, P100,P120、P150, P180, P220, P240

|

|

|

composition

|

Sic

|

≥98.5%

|

|

|

|

F.C

|

≤0.2%

|

|

|

|

Fe203

|

≤0.2%

|

|

|

|

Sio2

|

≤0.7%

|

|

|

|

AL

|

≤0.5%

|

|

|

|

LOL

|

<0.09%

|

|

|

|

PH

|

≤7

|

|

|

|

hardness

|

≥9.15

|

|

|

|

Density

|

3.95 g/ cm3

|

|

|

|

Maximum service temperature

|

1900

|

|

|

Physical

Characteristics

|

Melting Point

|

2250

|

|

|

Application

|

Bonded Abrasives and Coated abrasives

Blasting, surface Treatment, Rust Removal

Grinding/grinding wheel and polishing, etc

|

|

|

Our Advantages

FACTORY

ADVANTAGE

MEET

CUSTOMER

NEEDS

The purity of black silicon carbide refractory series is 88-98%, which can meet the purity needs of different customers.It can process products of various particle sizes according to customer requirementsBlack silicon carbide particle size sand is washed with acid and alkali to control free carbon, iron and aluminum and effectively remove internal impurities.

Application

APPLICATIONS:

Bonded & Industrial Abrasives

Coated Abrasives

Refractories & Ceramics

Hot Searches