- Product Details

- {{item.text}}

Quick Details

-

Center Height (mm):

-

850 mm

-

Max.Transformer Capacity(kVA):

-

35 kVA

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

transease

-

Motor Power (kw):

-

5.5

-

Weight (KG):

-

2100

-

Dimension(L*W*H):

-

3100*700*1200mm

-

Wire Diameter Range (mm):

-

0.08 - 0.5 mm

-

Name:

-

HV and LV winding machine

-

Center for high:

-

850 mm

-

The widest stroke of the wire:

-

800 mm

-

Maximum working moment:

-

max 800 N/M

-

Dimensions of wound spool:

-

40*40*950

-

Working speed (mechanical double speed):

-

0-240r/min

-

Speed way:

-

Stepless frequency control

-

Applicable scope of workpiece:

-

Outer diameter≤700mm, inner diameter ≥80mm,axial height≤800mm

-

Workpiece weight (coil):

-

Max:≤250kg

-

Number of layer insulation:

-

2 sets

Quick Details

-

Max. Load (KG):

-

250 KG

-

Coil Type:

-

round, rectangular, oval

-

Length of Axis (mm):

-

800 mm

-

Center Height (mm):

-

850 mm

-

Max.Transformer Capacity(kVA):

-

35 kVA

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

transease

-

Motor Power (kw):

-

5.5

-

Weight (KG):

-

2100

-

Dimension(L*W*H):

-

3100*700*1200mm

-

Wire Diameter Range (mm):

-

0.08 - 0.5 mm

-

Name:

-

HV and LV winding machine

-

Center for high:

-

850 mm

-

The widest stroke of the wire:

-

800 mm

-

Maximum working moment:

-

max 800 N/M

-

Dimensions of wound spool:

-

40*40*950

-

Working speed (mechanical double speed):

-

0-240r/min

-

Speed way:

-

Stepless frequency control

-

Applicable scope of workpiece:

-

Outer diameter≤700mm, inner diameter ≥80mm,axial height≤800mm

-

Workpiece weight (coil):

-

Max:≤250kg

-

Number of layer insulation:

-

2 sets

HORIZONTAL AUTOMATLC HV COIL WINDING MACHINE

Overview:

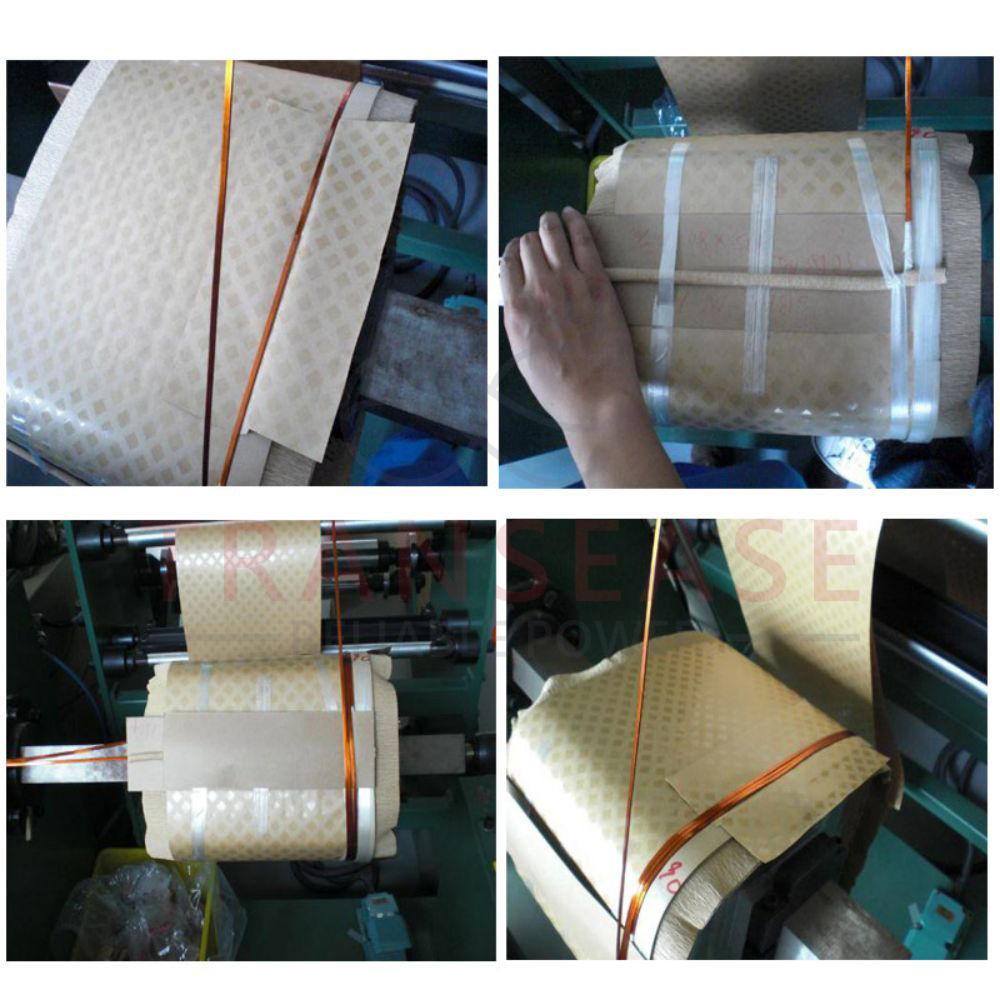

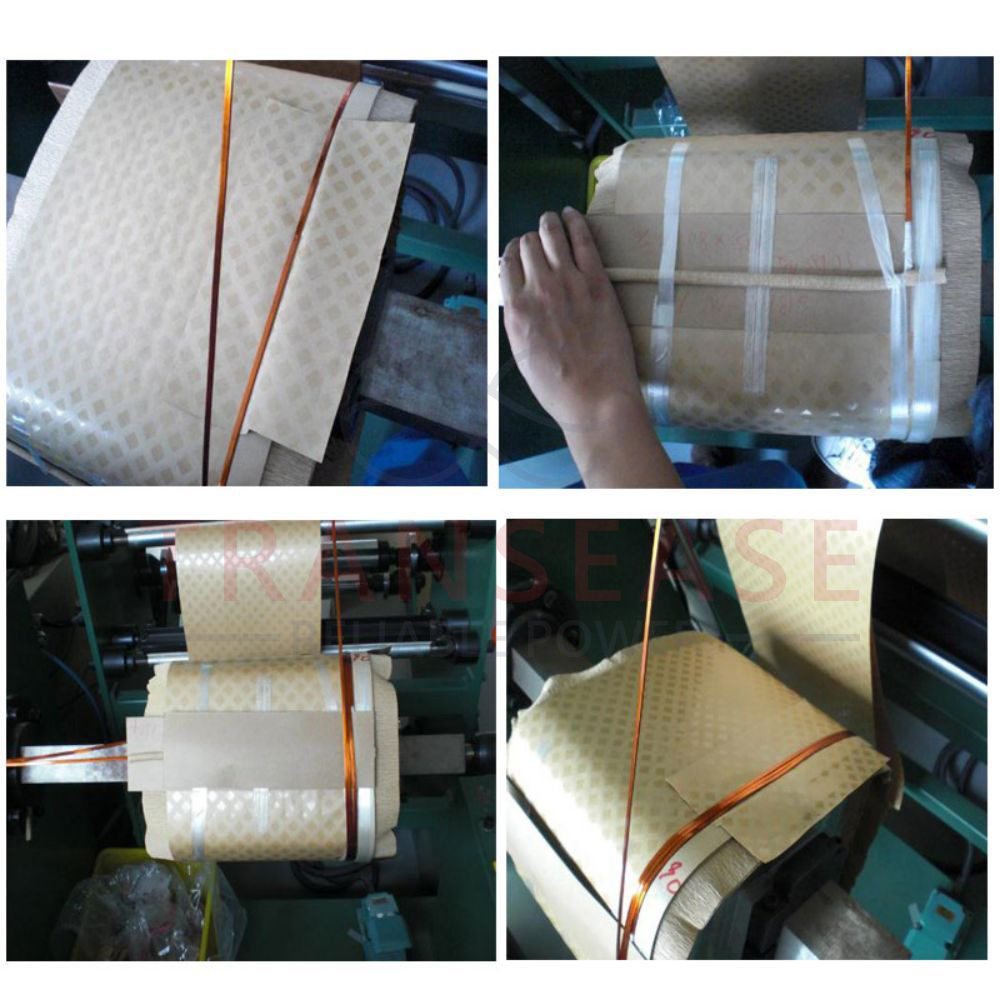

Type 800 automatic winding machine is used for all kinds of small and medium-sized slotted structure and amorphous alloy distribution transformer coil winding, rectangular structure for high voltage coil of dry and oil change, high-speed wirear velocity at 0-240 revolutions per minute, the main motor power 5.5 KW, coil radius of 400 mm Φ row wire distance is 800 mm, and can satisfy the wire diameter in (4.0) 0.2 Φ Φ enamelled copper or aluminium wire, (including flat wire 5 * 14) paint flat copper or aluminum wire, covers an area of 50 square and the following paper membrane bags of aluminium or copper flat wire, Mainly used in foreign 10KV transformer 25Kv transformer 33KV transformer 35KV transformer small-wire diameter transformer technology combined manufacturing, at the same time transformer/transformer dual-purpose equipment.

1.1:Equipment functions; 1 turn /5 turn winding speed can be set before starting the equipment. Low speed and slow speed can be used to start the equipment. 1 turn /5 advance deceleration process can be set for each layer to set the number of turns liter or the head position.

1.2:When the touch screen selects automatic control, when starting the operation of the device, start the device automatically with the foot point to the set number of turns or the set number of heads for each layer, and the device will automatically stop and rise the layer or head.

|

|

ZBR-800 |

|

|

1 |

Center for high |

850 mm |

|

2 |

The widest stroke of the wire |

8 00 mm |

|

3 |

Maximum working moment |

max 800 N/M |

|

4 |

Dimensions of wound spool |

40×40× 9 50 |

|

5 |

Working speed (mechanical double speed) |

0— 240 r/min |

|

6 |

Speed way |

Stepless frequency control |

|

|

|

Outer diameter≤ 7 00mm |

|

7 |

Applicable scope of workpiece |

The inner diameter ≥80mm |

|

|

|

The axial height ≤ 8 00mm |

|

8 |

Workpiece weight (coil): |

Max:≤2 5 0kg |

|

9 |

Number of layer insulation |

2 Set |

|

10 |

Applicable workpiece specification |

Paper roll diameter:≤ 400mm |

|

Inside diameter of paper roll 76mm |

||

|

The paper roll width≤ 8 00mm |

||

|

The thickness of the:0.08-0.5mm |

||

|

|

Maximum tension of layer insulation |

≤ 50 Nm |

|

11 |

Main motor power |

5.5 kw

|

|

12 |

Count range |

99999 |

|

13 |

Flat wire: |

Max 5 ×1 4 mm |

|

|

Wire specifications |

ΦΦ0.2mm×Φ 4.0 mm |

|

14 |

Minimum adjustment wire diameter |

0.01mm |

|

15 |

wire spacing setting range |

0-15mm |

|

16 |

Adjustment of wire gauge for flat wire row wheel |

0-15mm |

|

17 |

The row wheel adjusts the distance vertically |

0-300mm |

|

18 |

Main shaft supports jacking device |

Rotatable tripod structure |

|

19 |

Flat wire material frame tension supply |

electric |

|

20 |

Axis diameter of reel |

Φ36mmΦ30mm |

|

21 |

Number of shaft |

1 the root |

|

|

Outer diameter |

MaxØ 6 50mm |

|

22 |

The width of the |

150-300mm |

|

22.1 |

The weight of the |

20 0KG |

|

23 |

Material frame moving form |

Main shaft wire linkage movement |

|

24 |

Winding way |

Straight and backwards |

|

25 |

Maximum tension of flat wire |

10 0N |

|

26 |

The weight |

about 2 1 00kg |