- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

p1-43

Quick Details

-

Customized support:

-

Please contact us for details

-

Place of Origin:

-

Japan

-

Brand Name:

-

OVIT

-

Model Number:

-

p1-43

Products Description

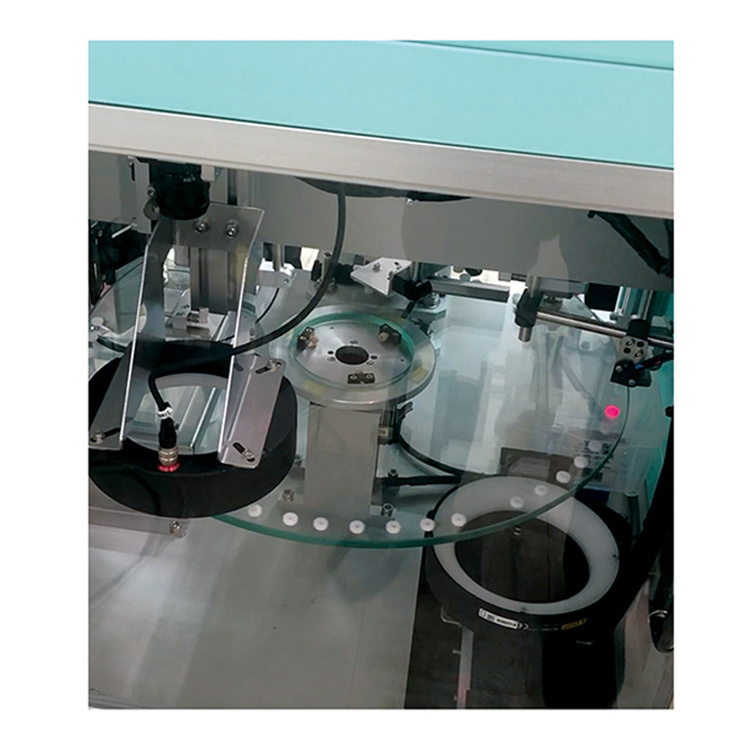

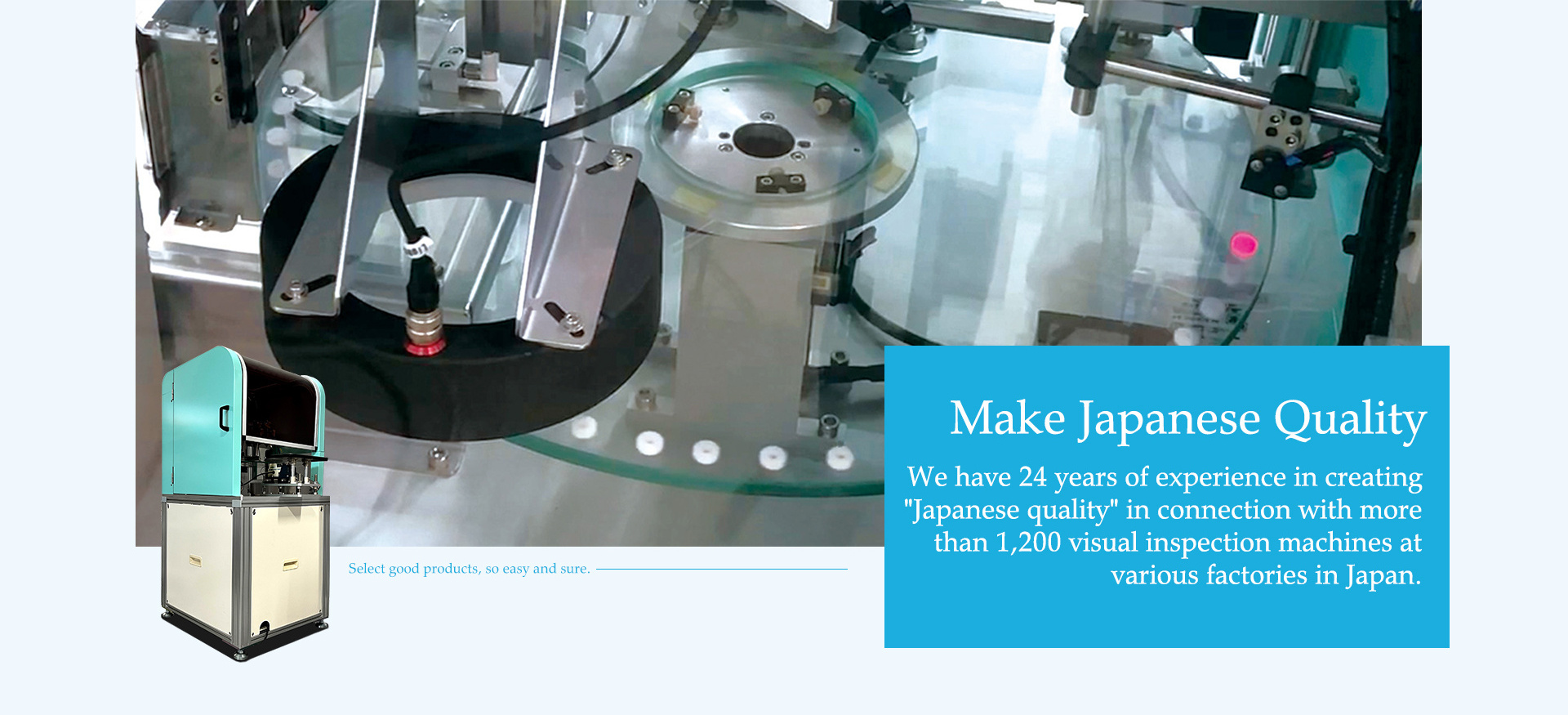

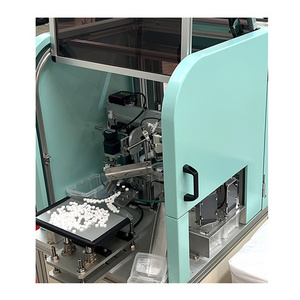

1) Enables very simple and reliable inspection.

It checks whether or not an item matches the conforming item when viewed from both the front and rear.

All defects are detected as discrepancies with the conforming item.

Our algorithm has a proven track record in more than 1,000 machines at production facilities in Japan.

2) Improves productivity over human visual inspectors by more than fourfold

It performs a high speed inspection of all items at a rate of 3 units per second.

This inspection speed greatly exceeds human capabilities.

3) It can inspect all kinds of objects.

• Up to 30mm square size

• Stable when on a flat surface

• Does not stain glass surfaces

It can inspect all kinds of objects if they meet these conditions.

It can also be retasked to a different inspection subject.

The construction of the equipment is very simple, so the serviceability is excellent.

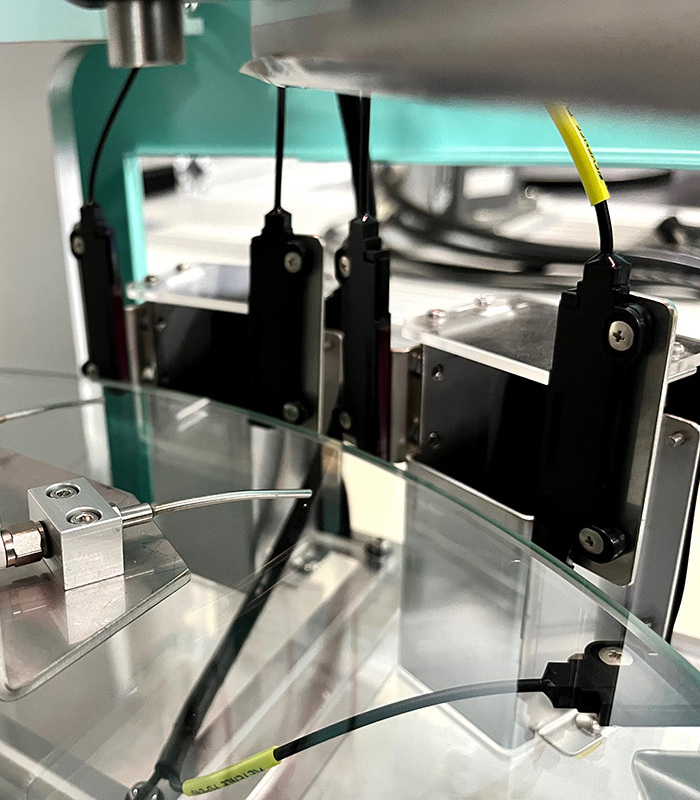

4) We use proven good quality components.

The equipment is controlled by a KEYENCE sequencer.

Our proprietary image processing controller uses the HALCON image processing library.

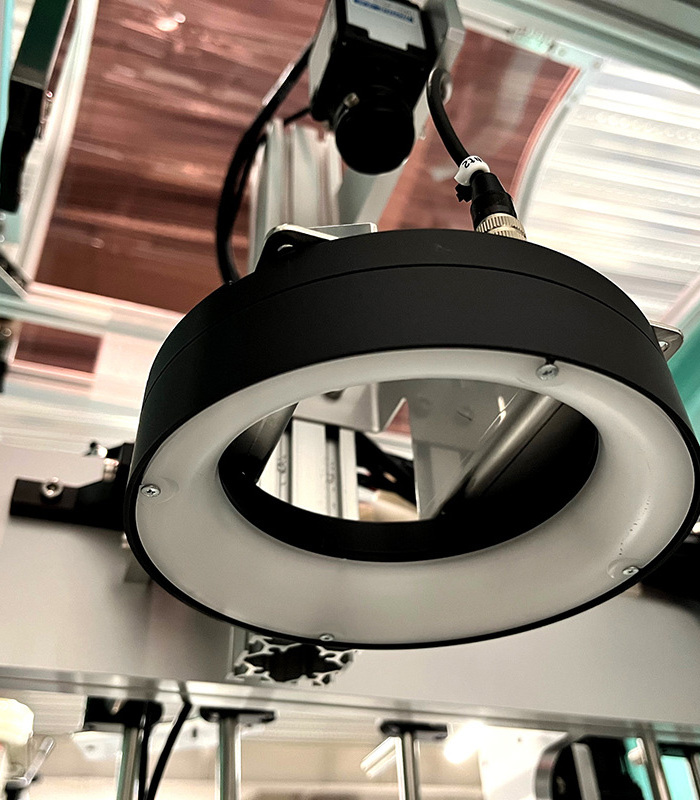

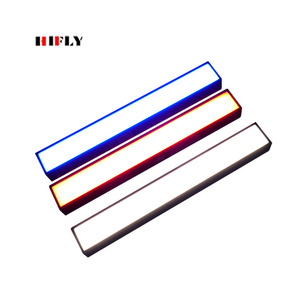

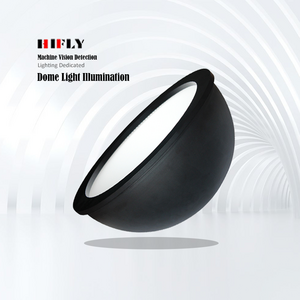

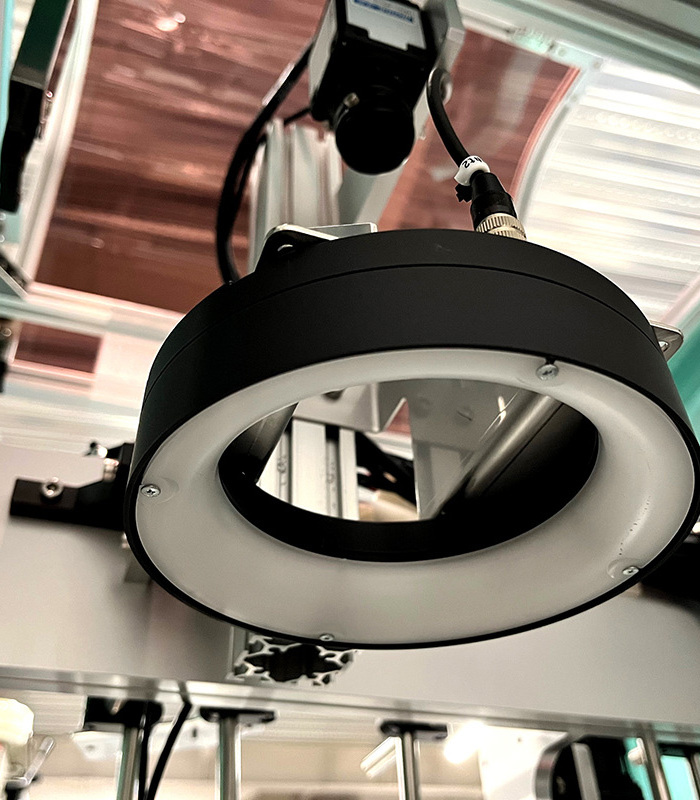

It uses a Basler camera and CCS lighting.

It checks whether or not an item matches the conforming item when viewed from both the front and rear.

All defects are detected as discrepancies with the conforming item.

Our algorithm has a proven track record in more than 1,000 machines at production facilities in Japan.

2) Improves productivity over human visual inspectors by more than fourfold

It performs a high speed inspection of all items at a rate of 3 units per second.

This inspection speed greatly exceeds human capabilities.

3) It can inspect all kinds of objects.

• Up to 30mm square size

• Stable when on a flat surface

• Does not stain glass surfaces

It can inspect all kinds of objects if they meet these conditions.

It can also be retasked to a different inspection subject.

The construction of the equipment is very simple, so the serviceability is excellent.

4) We use proven good quality components.

The equipment is controlled by a KEYENCE sequencer.

Our proprietary image processing controller uses the HALCON image processing library.

It uses a Basler camera and CCS lighting.

|

|

Standard Type

|

Structural Flaw Reinforcement Type

|

|

Discoloration/Staining

|

〇

|

◎

|

|

Flaws/Deformation

|

△

|

◎

|

|

Estimated Maximum Throughput

|

10 units/second

|

3 units/second

|

|

Price

|

ー

|

+¥2.5 million

|

|

Cameras

|

Basler 1.3 megapixel

|

KEYENCE VJ 2 megapixel

|

|

Photography

|

Imaging by ring illumination Once each front and back

|

Imaging by switching illumination direction at high speed

|

Product Usage

Product: Visual inspection equipment for industrial products

Users: Manufacturers of small plastic parts and small metal parts

Inspection Subjects:

Small parts up to 30mm square in size

Objects that are stable on a flat surface

Objects that do not stain glass surfaces

It is particularly well-suited for small plastic parts and small metal parts.

Inspection Details:

Roughly 30 conforming items are photographed, and the conformance tolerances are determined statistically.

If an item is within these conformance tolerances, it is judged to be a conforming item.

All flaws are detected as discrepancies with a conforming item.

This method is simpler, more reliable, and cheaper than deep learning.

Method of Operation:

When an inspection subject is inserted, it checks whether or not the front and rear match the conforming item, chooses if it is a conforming item or non-conforming item, and ejects it.

Results:

It is capable of high speed inspection, and a fourfold increase in productivity over human visual inspectors has been reported.

Inspection of all units produces consistent quality.

Users: Manufacturers of small plastic parts and small metal parts

Inspection Subjects:

Small parts up to 30mm square in size

Objects that are stable on a flat surface

Objects that do not stain glass surfaces

It is particularly well-suited for small plastic parts and small metal parts.

Inspection Details:

Roughly 30 conforming items are photographed, and the conformance tolerances are determined statistically.

If an item is within these conformance tolerances, it is judged to be a conforming item.

All flaws are detected as discrepancies with a conforming item.

This method is simpler, more reliable, and cheaper than deep learning.

Method of Operation:

When an inspection subject is inserted, it checks whether or not the front and rear match the conforming item, chooses if it is a conforming item or non-conforming item, and ejects it.

Results:

It is capable of high speed inspection, and a fourfold increase in productivity over human visual inspectors has been reported.

Inspection of all units produces consistent quality.

Hot Searches