- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380v

-

Power:

-

10KW

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

6000X2000X2500MM

-

NAME:

-

Yogurt milk processing machine

-

Keywords:

-

Milk Pasteurazation Machine

-

Material:

-

SUS304/316L Stainless Steel

-

Advantage:

-

Easy Operation High Efficiency

-

MOQ:

-

1unit

-

Raw material:

-

Goat Milk Cow milk

-

Processing:

-

Mixing + Pasteurizing+Homogenizing

-

Function:

-

Industrial Milk Production

-

After Warranty Service:

-

Video technical support

Quick Details

-

Marketing Type:

-

Hot Product 2022

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

YGT

-

Voltage:

-

220/380v

-

Power:

-

10KW

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

6000X2000X2500MM

-

NAME:

-

Yogurt milk processing machine

-

Keywords:

-

Milk Pasteurazation Machine

-

Material:

-

SUS304/316L Stainless Steel

-

Advantage:

-

Easy Operation High Efficiency

-

MOQ:

-

1unit

-

Raw material:

-

Goat Milk Cow milk

-

Processing:

-

Mixing + Pasteurizing+Homogenizing

-

Function:

-

Industrial Milk Production

-

After Warranty Service:

-

Video technical support

Product Description

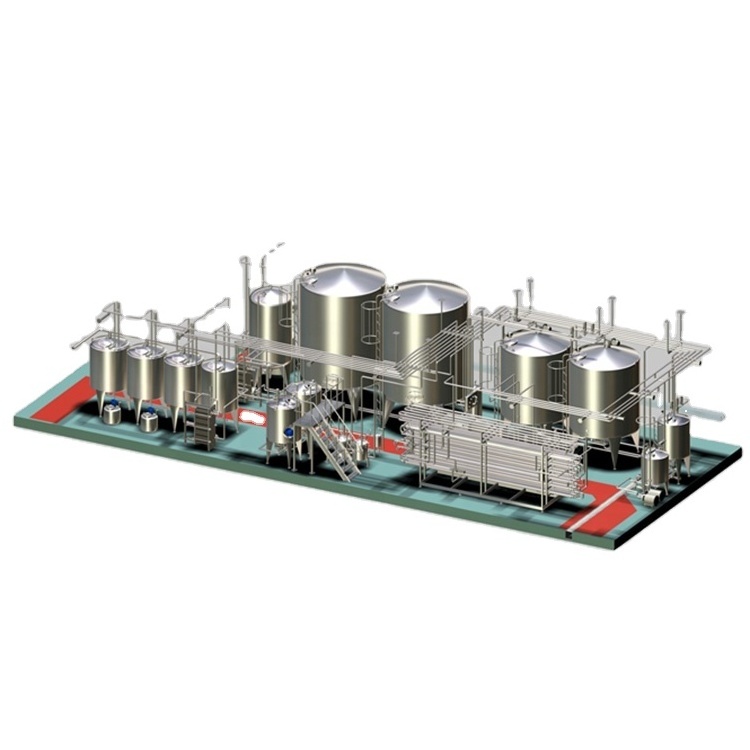

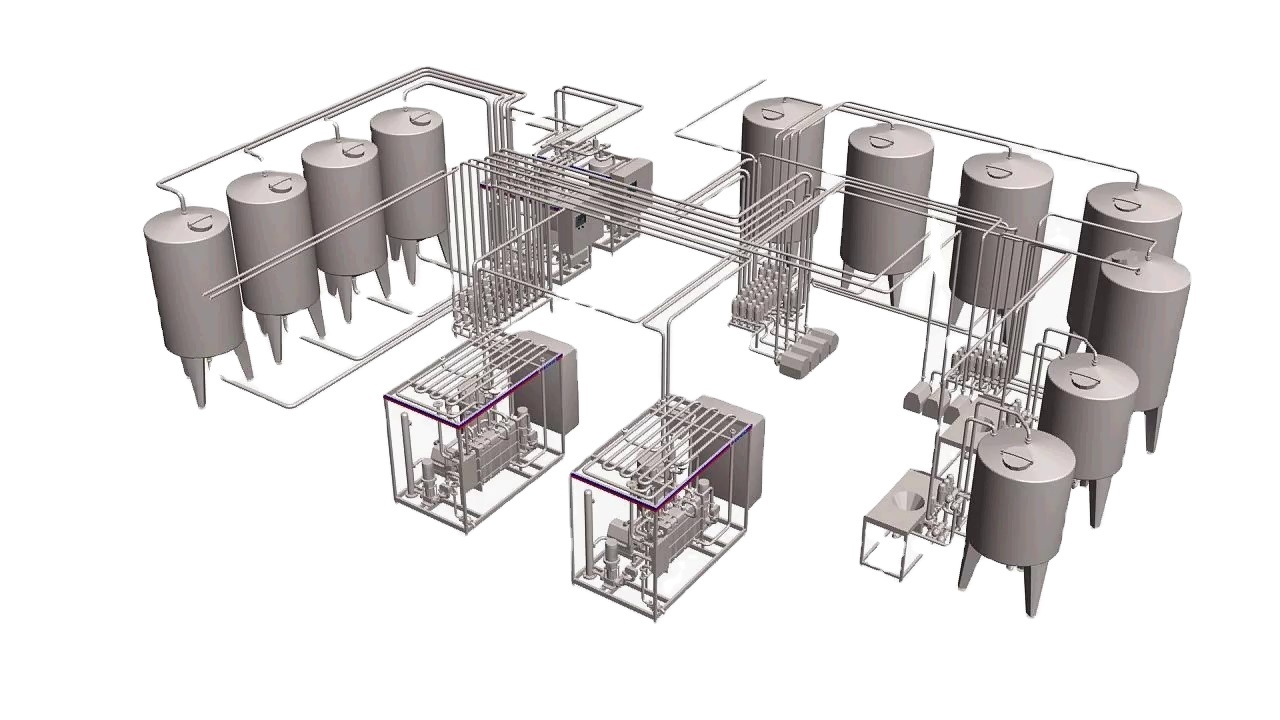

Milk Production Line

The integrated system compose by collection tank, mixing tank, homogenizer, sterilizer system at one platform. which makes it easy and safe to use and simple to maintain a integrated configuration, with a compact design based on standardized building blocks. the combo plant remains easy operation, service-friendly.

Advantage

:

with preparation tank, sterilization, homogenizer, mixing/fermentation tank ,CIP system etc. integrated with ready pump and pipe fitting to convenient site connection. Which could custom made and be flexible for milk, yoghurt, cream, beverage etc product.

|

Project Name

|

Milk Production Line

|

Data

|

|

1

|

Milk collection tank

|

100-500L

|

|

2

|

Cooling system

|

plate heat exchange + chiller

|

|

3

|

Blending tank

|

500L/1000L/2000L

|

|

4

|

Transfer pump

|

centrifugal type, 3000L/h

|

|

5

|

Homogenizer

|

500-2000L/h,, 25Mpa

|

|

6

|

Sterilizer

|

plate structure

|

|

7

|

Filling machine

|

pouch bag cold filling

|

|

8

|

pipe connection and PLC control

|

integrated on platform with cabinet

|

Capacity apply for 500-2000L/h milk , 2000L-5000L daily.

Detailed Images

Plate Sterilizer

Description

Structure: plate type

Composed by PHE, tank, pump, steam valve, PLC, pipping as one system

Function: to heat and cool milk, prolong the milk shelf time, also keep milk taste and nutrition, this is most economical equipment for dairy milk , beverage juice industry

Capacity: 500Lph as mini, with 1000L/h and 2000l/h for monoblock system optional

Material: SUS304

Temperature Flowchart: 4c-85c/20s-4c

(temperature and holding time could adjustable as per site need)

(temperature and holding time could adjustable as per site need)

Homogenizer Description

Max pressure: 25Mpa

F

low: 500L/h as mini, with 1000L/h and 2000l/h for monoblock system optional

Feeding pressure: 0.2-0.3Mpa

Structure: 3piston,2stage

Material: SUS304

Function: by high pressure to emulsify molecular and make liquid more even, prevent separation and improve taste

Application: for milk, juice etc food

Related Products

tubular sterilizer

plate heat exchange

cooling tank

Packing&Shipping

shipment of milk plant equipment

Company Introduction

Shanghai Qingji Beverage Machinery Co., Ltd. is a leading technology manufacturing enterprise since 2006, with an elite

engineering team expert at the heat exchange and flow design,research and development, forcus on dairy and beverage processing industry.

Our main products are Plate Heat Exchanger, UHT Sterilizer, milk Pasteurizer, CIP system, sanitary centrifugal pump etc,a lso have the ability to handle turnkey project .

engineering team expert at the heat exchange and flow design,research and development, forcus on dairy and beverage processing industry.

Our main products are Plate Heat Exchanger, UHT Sterilizer, milk Pasteurizer, CIP system, sanitary centrifugal pump etc,a lso have the ability to handle turnkey project .

Our Services & Strength

- technical consultant for dairy processing

- project layout design for new system line

FAQ

Q: What are the main configurations of the milk plant?

A: Main configuration: material system, high-temperature hot water system, degassing system (optional), high-pressure homogenizing system (optional), CIP system, self-sterilizing aseptic system (optional) and control system.

Q: Where is the sterilizer mainly used?

A: Food industry: tea drinks, ice cream, fruit juice and jam, dairy products, plant protein plants and other food and beverage

B.Beverage industry: alcoholic beverage, fruit juice beverage, mixed dairy products, sugar, ice cream, fruit juice, pasteurized

milk, peanut milk, protein milk, soy milk, dairy products, beverage, etc

Q: How long is the warranty?

A: 1-2 years

A: Main configuration: material system, high-temperature hot water system, degassing system (optional), high-pressure homogenizing system (optional), CIP system, self-sterilizing aseptic system (optional) and control system.

Q: Where is the sterilizer mainly used?

A: Food industry: tea drinks, ice cream, fruit juice and jam, dairy products, plant protein plants and other food and beverage

B.Beverage industry: alcoholic beverage, fruit juice beverage, mixed dairy products, sugar, ice cream, fruit juice, pasteurized

milk, peanut milk, protein milk, soy milk, dairy products, beverage, etc

Q: How long is the warranty?

A: 1-2 years

Hot Searches