- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

2500

-

Table Travel (Z) (mm):

-

200

-

Marketing Type:

-

New Product 2022

-

Cutting Accuracy(mm):

-

±0.1mm

-

Brand Name:

-

CHINSAIL

-

Voltage:

-

(415v/50hz), 380V/50HZ, ( 220v/60hz), 3 phrase

-

Rated Power:

-

20KW

-

Dimension(L*W*H):

-

2700*1700*1000mm

-

Year:

-

2022

-

Weight (KG):

-

3500 KG

-

Key words:

-

Industrial Glass Cutter

-

Glass Thickness:

-

1-40mm

-

Continuous Working Pressure:

-

350-380mpa

-

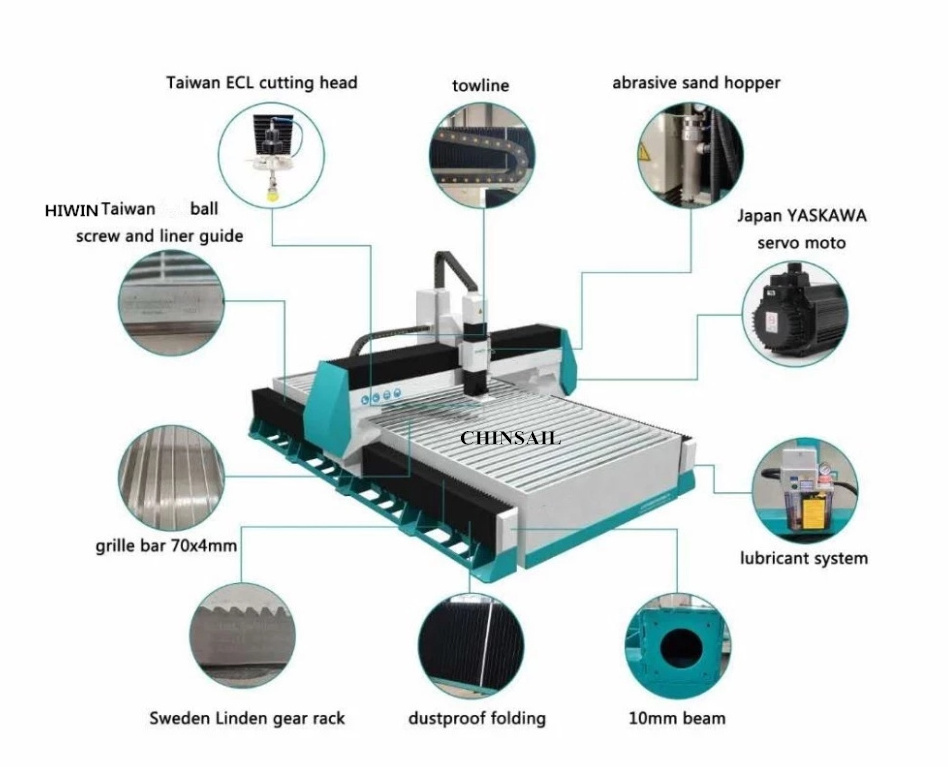

Way of drive:

-

servo motor and driver

-

Cutting thickness:

-

0-200mm

-

Max pressure:

-

420mpa

-

linear guider:

-

imported from TAIWAN Hiwin

-

Application:

-

Industrial Metal Cutting

-

Cutting mode:

-

High Pressure Water

-

CNC System & Software:

-

WEIHONG CNC

Quick Details

-

Place of Origin:

-

Shandong, China

-

Repeatability (X/Y/Z) (mm):

-

±0.1mm

-

Table Travel (X) (mm):

-

1300

-

Table Travel (Y) (mm):

-

2500

-

Table Travel (Z) (mm):

-

200

-

Marketing Type:

-

New Product 2022

-

Cutting Accuracy(mm):

-

±0.1mm

-

Brand Name:

-

CHINSAIL

-

Voltage:

-

(415v/50hz), 380V/50HZ, ( 220v/60hz), 3 phrase

-

Rated Power:

-

20KW

-

Dimension(L*W*H):

-

2700*1700*1000mm

-

Year:

-

2022

-

Weight (KG):

-

3500 KG

-

Key words:

-

Industrial Glass Cutter

-

Glass Thickness:

-

1-40mm

-

Continuous Working Pressure:

-

350-380mpa

-

Way of drive:

-

servo motor and driver

-

Cutting thickness:

-

0-200mm

-

Max pressure:

-

420mpa

-

linear guider:

-

imported from TAIWAN Hiwin

-

Application:

-

Industrial Metal Cutting

-

Cutting mode:

-

High Pressure Water

-

CNC System & Software:

-

WEIHONG CNC

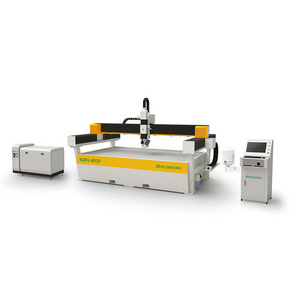

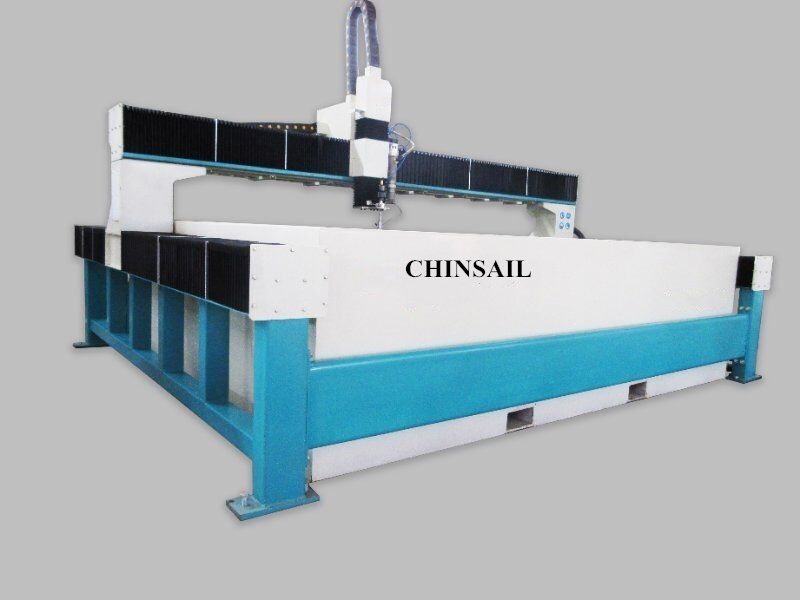

CHINSAIL 3 Axis 3D Waterjet machine 1530 CNC Water jet Cutting machine for marble granite glass cutting water jet cutter

Email: info(@)chinsailcnc.com, whatsapp/Skype:+86 1886 5928 760

| Introduction of water jet cutting machine | ||||

|

A full set of abrasive waterjet cutting machine includes work table, pump,CNC controller, High pressure system with cooling system, Auto abrasive feeder, Water treatment and Abrasive removal system,etc.

A full set of abrasive waterjet cutting machine includes work table, pump,CNC controller, High pressure system with cooling system, Auto abrasive feeder, Water treatment and Abrasive removal system,etc.

|

||||

|

||||

| DIRECT DRIVE PUMP | ||||

|

||||

| Application & Cutting speed | ||||

| Cutting Samples | ||||

|

* Stone/Ceramic industries such as used for countertops, art puzzles, flooring Inlays and mosaics.

* Glass industry , such as bathroom glass, shop window glass, automotive glass and appliance glass.

* Metal industries such as Decoration, decoration in the stainless steel and other metal cutting process, equipment cover cutting, Cutting of metal parts. * Gasket Cutting * Foam Product Cutting. |

| Production process |

| FAQ |

|

1. What kind of material does your water jet cutting machine can cut?

Contact:

Email: info(@)chinsailcnc.com, whatsapp/Skype:+86 1886 5928 760

|