- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

GookiiTech

-

Voltage:

-

12V

-

Power:

-

18,000W

-

Weight (KG):

-

50

-

Tank Inner Size:

-

L1500*W800*H1000mm

-

Tank Material:

-

10mm PP

-

Chemical Capacity:

-

1100 Liter/ 290 US Gallons

-

Power Configurations:

-

12V, 1500A

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Machine Type:

-

Electropolishing Machine

-

Core Components:

-

Heating System, Thermostat, Tank, Rectifier

-

Brand Name:

-

GookiiTech

-

Voltage:

-

12V

-

Power:

-

18,000W

-

Weight (KG):

-

50

-

Tank Inner Size:

-

L1500*W800*H1000mm

-

Tank Material:

-

10mm PP

-

Chemical Capacity:

-

1100 Liter/ 290 US Gallons

-

Power Configurations:

-

12V, 1500A

Products Description

|

Products Name

|

Electrolytic Polishing Bath / Electroplating Tanks

|

|

|

|

Material

|

Tank: 10mm PP (Polypropylene)

|

|

|

|

Tank Inner Size

|

1500*800*1000mm

|

|

|

|

Chemical Capacity

|

1100 Liters/ 290 US Gallons

|

|

|

|

Weight of Chemical

|

1100 Kg/ 2425 Pounds

|

|

|

|

Power Configurations

|

1500A, 12V

|

|

|

|

Warranty

|

12 Months

|

|

|

|

Other Parameter

|

1. IGBT imported chip, original packaging, and the overall iron shell is baked with outdoor paint.

2. Cooling method: air-cooled.

3. The efficiency is 90%.

4. Working hours: long-term operation.

5. Protection mode: over-current, over-voltage. overheat.

6. Current and voltage accuracy: 1%. One heating system thermostat and one heating tube. Conductive copper is 1 meter each. The hanger is not included, the hanger needs to be customized according to the work-piece.

|

|

|

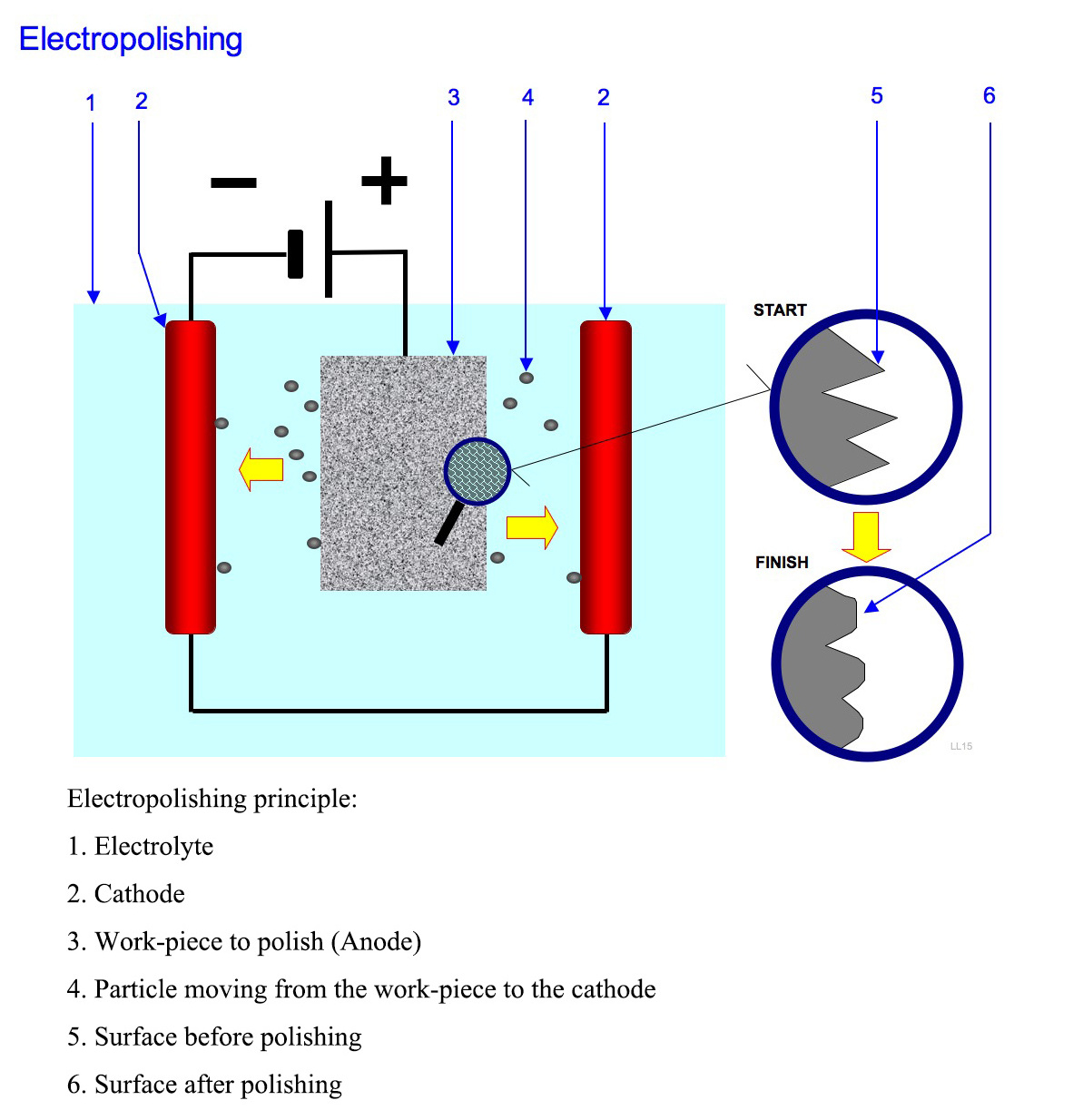

What is e

lectropolishing

?

Electropolishing, also known as electrochemical polishing, anodic polishing, or electrolytic polishing (especially in the metallography field), is an electrochemical process that removes material from a metallic workpiece, reducing the surface roughness by levelling micro-peaks and valleys, improving the surface finish. Electropolishing is often compared to, but distinctly different from, electrochemical machining. It is used to polish, passivate, and deburr metal parts. It is often described as the reverse of electroplating. It may be used in lieu of abrasive fine polishing in microstructural preparation.

Performance characteristics

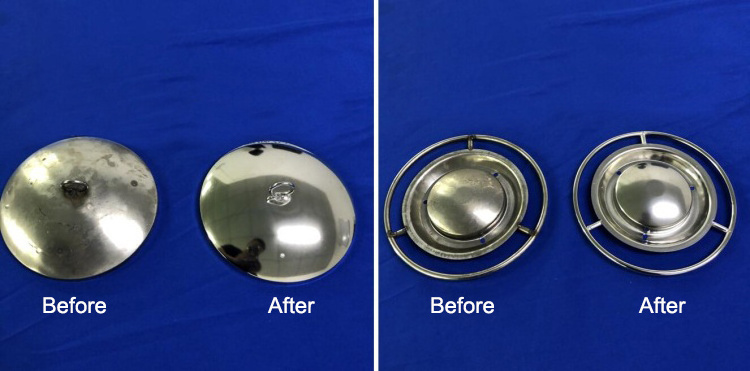

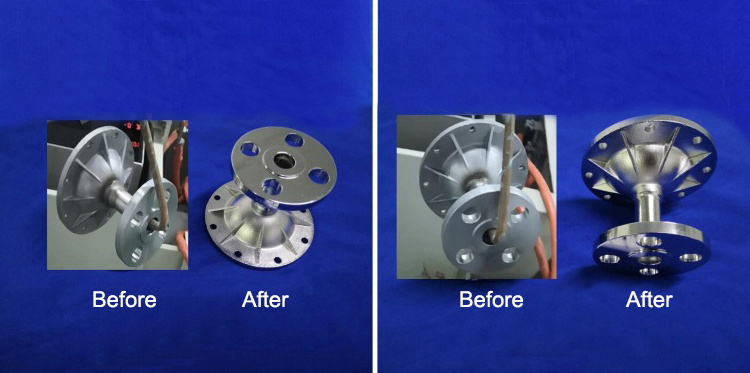

1) Electrolytic polishing can achieve dead corners that cannot be touched by mechanical polishing, such as pits, complex parts, filaments, films, wire meshes, etc.

2) The polishing efficiency is high and the quality is good, and the surface of the product can be made into a mirror bright effect within a few minutes. In addition, the polishing equipment has a long service life, high-frequency pulses, and practical power saving.

3) Electrolytic polishing can preferentially dissolve the deformed layer dislocations, hole accumulation and isopotential structure on the metal surface, thereby obtaining an equipotential surface and greatly improving the corrosion resistance of stainless steel.

Main Feature

1) High reliability, resistant to harsh voltage environment and harsh humid environment.

2) Small size and light weight.

3) High efficiency, high precision, high stability, low ripple.

4) It can operate in two modes of steady current and voltage regulation, and the output current and voltage can be adjusted separately.

Spare Parts

1: Electropolishing Dipping Tank 1500x800x1000mm------------1 set

2: Ballast Resistor (Timer with Alarm &Temperature Controller) -----1 set

3: Anode Copper Pipe --------------------------------------------------------1 pc

4: Cathode Copper Plate ---------------------------------------------------2 pcs

5: Cathode Lead Plate --------------------------------------------------------8 pcs

6: Quartz Heater ----------------------------------------------------------------3 pcs

7: Copper Wire 1500A ---------------------------------------------------------4 pcs

8: Fixture tool ( Electrolytic hanger) ----------------------------------1 pc

2: Ballast Resistor (Timer with Alarm &Temperature Controller) -----1 set

3: Anode Copper Pipe --------------------------------------------------------1 pc

4: Cathode Copper Plate ---------------------------------------------------2 pcs

5: Cathode Lead Plate --------------------------------------------------------8 pcs

6: Quartz Heater ----------------------------------------------------------------3 pcs

7: Copper Wire 1500A ---------------------------------------------------------4 pcs

8: Fixture tool ( Electrolytic hanger) ----------------------------------1 pc

Recommend Products

Hot Searches