- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Single-phase 220 VAC 50 / 60 Hz

-

Power:

-

2000 W

-

Dimension(L*W*H):

-

48" * 28" * 32"

-

Weight (KG):

-

200

-

Product name:

-

magnetron sputtering vacuum coating equipment

-

DC source:

-

500 W power for coating metallic materials

-

RF source:

-

300 W power, 13.56 MHz frequency for coating non-conductive materials

-

Vacuum chamber:

-

300 mm Dia. x 300 mm Height

-

Chamber material:

-

Stainless Steel 304/316

-

Viewport:

-

Two pieces of 100 mm Dia.

-

Sample holder size:

-

140 mm Dia.

-

The holder temperature:

-

adjustable from RT to 500 °C max

-

Gas Flow Control:

-

Two precision mass flow controllers (MFC)

-

Water Chiller:

-

Flow rate: 16 L/min

Quick Details

-

Machine Type:

-

Magnetron Plasma Sputtering Coater, Coating Equipment

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MTI

-

Voltage:

-

Single-phase 220 VAC 50 / 60 Hz

-

Power:

-

2000 W

-

Dimension(L*W*H):

-

48" * 28" * 32"

-

Weight (KG):

-

200

-

Product name:

-

magnetron sputtering vacuum coating equipment

-

DC source:

-

500 W power for coating metallic materials

-

RF source:

-

300 W power, 13.56 MHz frequency for coating non-conductive materials

-

Vacuum chamber:

-

300 mm Dia. x 300 mm Height

-

Chamber material:

-

Stainless Steel 304/316

-

Viewport:

-

Two pieces of 100 mm Dia.

-

Sample holder size:

-

140 mm Dia.

-

The holder temperature:

-

adjustable from RT to 500 °C max

-

Gas Flow Control:

-

Two precision mass flow controllers (MFC)

-

Water Chiller:

-

Flow rate: 16 L/min

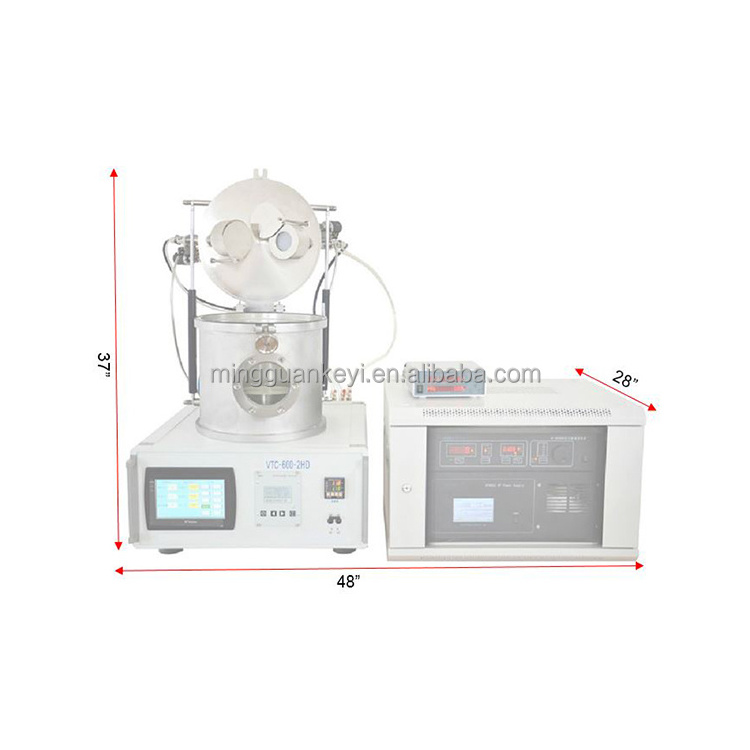

DC/RF Dual-Head High Vacuum 2” Magnetron Plasma Sputtering Coater - VTC-600-2HD-LD

VTC-600-2HD-LD is a compact magnetron sputtering system with dual 2" target sources, e.g., one DC source for coating metallic film, and the other RF source for coating non-metallic material. This coating system is designed for coating both single or multiple film layers for a wide range of materials, such as alloy, ferroelectric, semiconductor, ceramic, dielectric, optical, PTFE, etc.

SPECIFICATIONS

|

|

· Single-phase 220 VAC 50 / 60 Hz · 2000 W (including a vacuum pump and water chiller) |

|

|

· Two sputtering power sources are integrated into one control box o DC source: 500 W power for coating metallic materials o RF source: 300 W power, 13.56 MHz frequency for coating non-conductive materials |

|

|

· Two 2-inch Magnetron sputtering heads with water cooling jackets and shutters are included o One is connected to DC source for coating metallic materials o The other one is connected to the RF source for non-conductive materials o Target size requirement: 2" diameter with thickness of 0.1 - 5 mm · Customized coater: Two DC heads without RF; two RF heads without DC; 3 RF heads are available upon request · Optional: 148 cm RF cable can be ordered at extra cost for the replacement |

|

|

· Vacuum chamber: 300 mm Dia. x 300 mm Height, made of stainless steel · Viewport: Two pieces of 100 mm Dia. glass. One fixed; one detachable for cleaning and replacement · Hinged type lid with pneumatic power pole allows easy target change |

|

|

· The sample holder is a rotatable and heatable stage made of the ceramic heater with copper cover · Sample holder size: 140 mm Dia. for. 4" wafer max · Rotation speed: 1 - 20 rpm adjustable for uniform coating · The holder temperature is adjustable from RT to 500 °C max (2 hr max) with accuracy +/- 1.0 °C via a digital temperature controller |

|

Gas Flow Control

|

· Two precision mass flow controllers (MFC) are installed to allow inlet of two types of gasses o Flow rate: 0 – 200 mL/min adjustable on the touch screen control panel · Air inlet valve is installed for vacuum release |

|

Vacuum Pump Station

|

· A mobile pump station with a rotary vane pump is included. The sputtering coater can be placed on top of the station · High vacuum condition is required for targets sensitive to oxygen, such as Al, Ti, Cr, etc. |

|

Water Chiller

|

· One digital temperature-controlled recirculating water chiller is included. o Refrigeration range: 5~35 °C o Flow rate: 16 L/min o Pump pressure: 14 psi |

|

Film Thickness Monitor

|

· Precise quartz film thickness monitor is optional, which is used for in-situ thickness measurement. Accuracy up to 1Å |

|

Overall Dimensions |

|

|

Net Weight of Coater |

· 160 kg |

|

Shipping Weight & Dimensions |

· Total 2 Pallets o #1: 520 lbs, 52" x 40" x 50" o #2: 420 lbs, 48" x 40" x 45 " |

|

Compliance

|

· CE approval |

|

Warranty |

· One-year limited warranty with lifetime support |

|

Application Notes

|

· A two-stage pressure regulator should be installed on the gas tank to limit the output pressure below 0.02 MPa. · Please use > 5N purity Argon gas for plasma sputtering. · For best performance, the non-conductive targets must be installed with a copper backing plate. Please refer to the instruction video below for target bonding · HIGH VOLTAGE! Sputtering heads connect to high voltage. For safety, the operator must shut down the RF / DC generator before sample loading and target changing operations · DO NOT use DI water in a water chiller. Use coolant, distilled water, or anti-corrosive additives with water |

=

=

1. Factory prices with the best quality.

2. One year free-of-charge maintenance for all the equipment

3. Customized service for special demand

4. Fast and flexible delivery, by sea, by air, by express

5. Quick response within 24 hours

How to order

1. If you are interested in our products, please tell us the model number and quantity.

2. We will make a proforma invoice for your order.

3. We will deliver the product ASAP on receipt of the payment

Guarantee

1. Guarantee for one year after shipment.

Payment

1.Telegraphic transfer

2.Western Union

3.Secure Payment through Alibaba

4.L/C

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.