- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Leizhan

-

Voltage:

-

380V

-

Power:

-

280KW

-

Dimension(L*W*H):

-

up to the type

-

Weight:

-

30 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

toilet rolls manufacturing machine

-

Raw Material:

-

recycling paper

-

Drive Way:

-

electric motor ,section drive

-

Control System:

-

frequency converter control

-

The paper grams(g/㎡):

-

13-30

-

Process Control:

-

roller balance, equipment surface blasting control

-

Performance:

-

reliable

-

Installation:

-

engineer available

-

Material:

-

stainless steel

Quick Details

-

Production Capacity:

-

Other

-

Product Type:

-

Toilet paper making machine

-

Processing Type:

-

Toilet paper making production line

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Leizhan

-

Voltage:

-

380V

-

Power:

-

280KW

-

Dimension(L*W*H):

-

up to the type

-

Weight:

-

30 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

toilet rolls manufacturing machine

-

Raw Material:

-

recycling paper

-

Drive Way:

-

electric motor ,section drive

-

Control System:

-

frequency converter control

-

The paper grams(g/㎡):

-

13-30

-

Process Control:

-

roller balance, equipment surface blasting control

-

Performance:

-

reliable

-

Installation:

-

engineer available

-

Material:

-

stainless steel

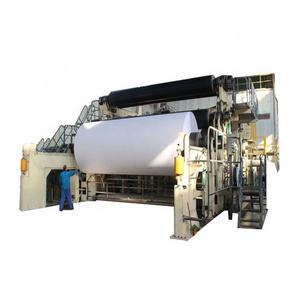

Toilet paper making equipment/ small toilet paper making machine price/ waste paper recycling machine production line

Toilet paper making machine brief introduction

Toilet paper making machine, trimmed paper width 1575mm,mainly used for making toilet paper. Full automatic toilet paper making machine mainly divided into 5 parts: headbox, fourdrinier wire part, press part, drying part and reeling part.

Toilet paper making machine structure

1.Headbox: Hydraulic headbox, through regulate and control input pulp main pipe inflow pressure and top & bottom lip’s opening degree of headbox to control and stabilize of the sieve slurry sizing head and the concentration.

2.Wire part: single fourdrinier, main parts: breast roll, forming plate, dehydration plate, vacuum box, couch roll, driven roller, guide wire roll and frame and so on, which equipped with 1 piece of forming wire.

3.Press part: divided into main press and carrier roller press. Main press is double roll press, and equip with each one high and low covered rubber metal roll; idler press is consist of carrier roll and 1 # large cylinder, and with one piece of covered rubber metal roll. Main press equip with guide felt roll and felt suction box, and with top & bottom felt. The carrier roll of idler roll press share one piece of top felt with main press. The main press and the idler roll press’s pressure method is corrugated tire pressure.

4.Drying part: 1# large cylinder:Φ3000/Φ3600 dryer cylinder, single transmission and equip with closed type hot air hood, 2 pieces of wrinkle doctor blade, 1 piece of clean doctor blade. Pressured way is air cylinder pressure. 2# large cylinder:Φ3000/Φ3600 dryer cylinder, single transmission, equip with dry wire and guide wire roll, no hood, and with 1 piece of clean doctor blade.Pressured way is gravity pressure.

5.Reeling part: Pneumatic horizontal type winding machine, air cylinder pressure.

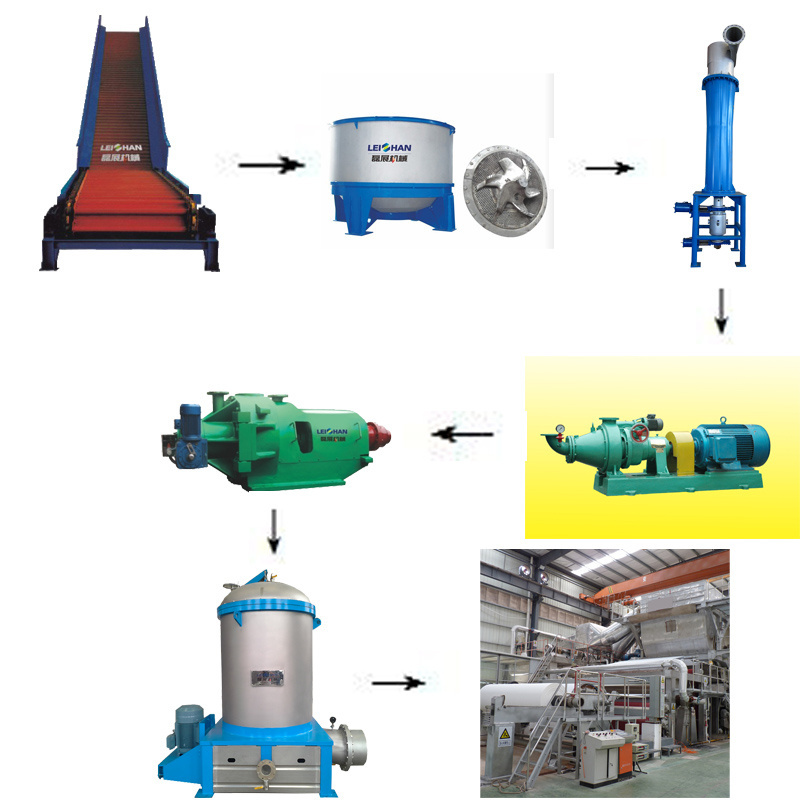

Toilet paper making machine production line

Chain convceyor →Middle consistency hydrapulper→High density cleaner→Conical refiner→DD refiner→Inflow pressure screen

Toilet paper making machine specification

| Paper grade | Toilet Paper, Tissue Paper |

| Trimmed width(mm) | 1575-3600 |

| Basis weight(g/m2) | 13-40 |

| Operating speed(m/min) | 180-800 |

| Production capacity(t/d) | 5-50 |

Toilet paper making machine main spare parts

Toilet paper making machine products

Toilet paper making machine packaging and delivery

1.International package(wooden case,carbon cast and pallet).

Leizhan service

Pre-Sales Service

1.Proposing the most suitable scheme and equipment for our clients.

2.Designing and fabricating targeted products according to the special requirements of clients.

3.Training periodically high qualified service technician.

After-Sales Service

1.Assisting our clients for foundation construction of equipment.

2.Dispatching engineers to install and debug equipment.

3.Training the first-line operators on site.

4.Regularly visit clients to solve production problems.

FAQ

A: We can offer the whole pulp and paper production line. From factory design to machine installation and training, our company can supply for you all.

Are your a manufacturer?

A: Yes. Of course we are. We are spealized in pulp & paper equipment manufacturing in China for 44 years. There are about 50 paper mills near our factory and most of them are using our machines. So, welcome to visit our factory and I believe you will be satisfied with our products.

What's your advantages?

A: We have 44 years experience in the field of paper making machine industry. 20000 square meters workshop with more than 200 staffs including 50 engineers.ISO9001:2000 and BV certification.Strict quality control of every procedure.

Why Choose Leizhan?