- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DABA

-

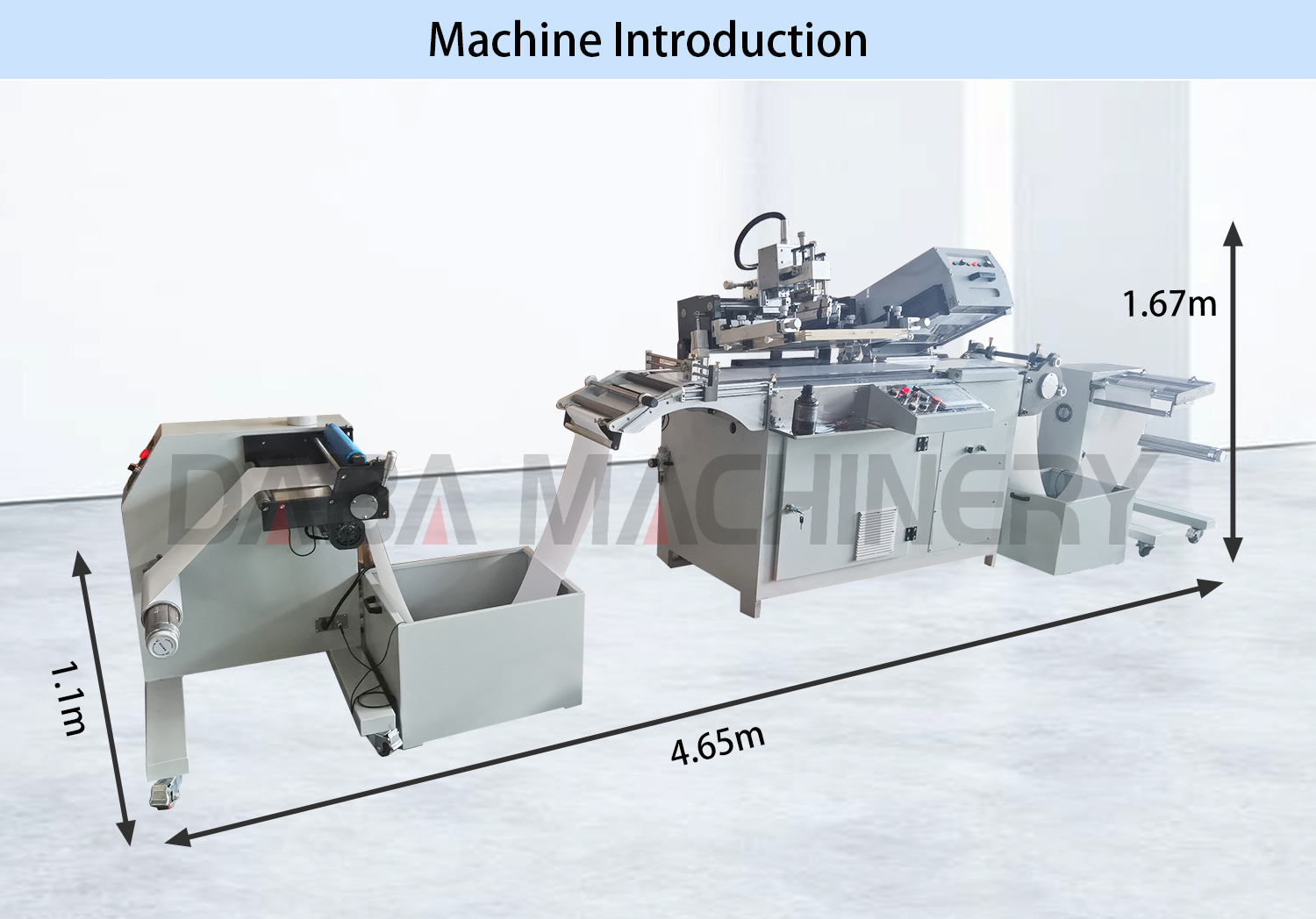

Dimensions(L*W*H):

-

4650* 1100 * 1670mm

-

Weight:

-

2500 KG

-

Certification:

-

CE

-

Printing speed:

-

1000~9000times/hour

-

Printing area:

-

350*400mm

-

Printing Material:

-

paper, film, etc

-

Printing Color:

-

one color

-

Function:

-

Pringting Label

-

After Warranty Service:

-

Online support, spare parts, engineer, etc.

-

Model:

-

DBSY

-

Machine type:

-

Automatic Screen Printer

-

Application:

-

Stickers

Quick Details

-

Condition:

-

New

-

Color & Page:

-

Multicolor

-

Voltage:

-

380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DABA

-

Dimensions(L*W*H):

-

4650* 1100 * 1670mm

-

Weight:

-

2500 KG

-

Certification:

-

CE

-

Printing speed:

-

1000~9000times/hour

-

Printing area:

-

350*400mm

-

Printing Material:

-

paper, film, etc

-

Printing Color:

-

one color

-

Function:

-

Pringting Label

-

After Warranty Service:

-

Online support, spare parts, engineer, etc.

-

Model:

-

DBSY

-

Machine type:

-

Automatic Screen Printer

-

Application:

-

Stickers

Product Description

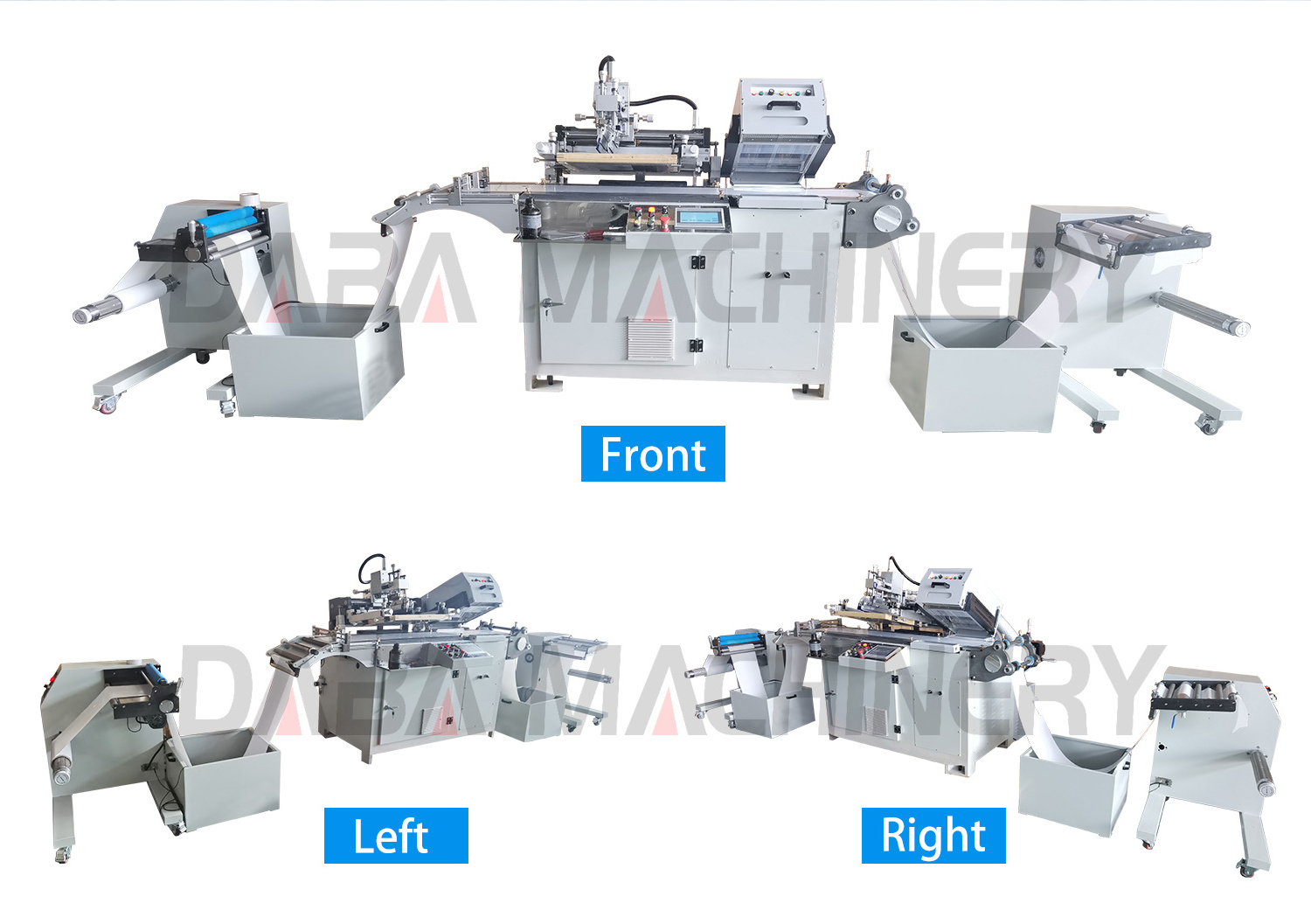

Machine Feature

1. It is suitable for printing products such as scratching silver and cosmetic labels, as well as overprinting and glazing of printed labels.

2. Printing materials in roll, self-adhesive paper, PVC, PET, PP, PC, PE, BOPP, and other printing materials.

3. Japan Yaskawa servo motor to ensure precision and stability.

4. English touch screen control panel

5. The user-friendly touch screen control panel for maximum operation convenience.

6. The print head rise and fall vertically for convenient access to screen and squeegee.

7. The squeegee and flood bar printing angle and pressure is adjustable to fit different printing tasks.

8. Using Panasonic high-precision follow-up electric eye, 3 colors, suitable for different materials and colors, the secondary color registration is accurate;

9. Aluminum alloy machine frame ensures high stability and no deformation.

10. Rust proof painting has been applied on the machine to prevent it from getting rust.

11. Castor wheels are installed on machine for easy movement.

12. Unwinding and rewinding units use air shaft, easy loading & unloading of film roll and prevent slippage.

13. The pitch feeding roller is driven by servo motor, ensuring exact length film feeding as per setting at all times.

14. Feeding and winding mechanism utilizes advanced sonar sensor for accurately sensing transparent and non-transparent film.

15. Precision linear motion guides are used on horizontal slide way for extremely smooth and stable printing head stroke.

16. The machine is equipped with 2 sets of UV lamp to efficiently and quickly dry the ink.

17. High-quality aluminum alloy screen frame, convenient for printing work.

2. Printing materials in roll, self-adhesive paper, PVC, PET, PP, PC, PE, BOPP, and other printing materials.

3. Japan Yaskawa servo motor to ensure precision and stability.

4. English touch screen control panel

5. The user-friendly touch screen control panel for maximum operation convenience.

6. The print head rise and fall vertically for convenient access to screen and squeegee.

7. The squeegee and flood bar printing angle and pressure is adjustable to fit different printing tasks.

8. Using Panasonic high-precision follow-up electric eye, 3 colors, suitable for different materials and colors, the secondary color registration is accurate;

9. Aluminum alloy machine frame ensures high stability and no deformation.

10. Rust proof painting has been applied on the machine to prevent it from getting rust.

11. Castor wheels are installed on machine for easy movement.

12. Unwinding and rewinding units use air shaft, easy loading & unloading of film roll and prevent slippage.

13. The pitch feeding roller is driven by servo motor, ensuring exact length film feeding as per setting at all times.

14. Feeding and winding mechanism utilizes advanced sonar sensor for accurately sensing transparent and non-transparent film.

15. Precision linear motion guides are used on horizontal slide way for extremely smooth and stable printing head stroke.

16. The machine is equipped with 2 sets of UV lamp to efficiently and quickly dry the ink.

17. High-quality aluminum alloy screen frame, convenient for printing work.

Specification

|

Model

|

DBSY-350

|

DBSY-420

|

|

Max. Substrate Width

|

350mm

|

420mm

|

|

Max. Printing Area

|

350*400mm

|

400*500mm

|

|

Max. Printing Speed

|

1000~9000times/hour

|

1000~9000times/hour

|

|

Screen Frame Size

|

550*700mm

|

550*800mm

|

|

Printing Precision

|

±0.20mm

|

±0.20mm

|

|

UV Dryer Power

|

7.2KW

|

7.2KW

|

|

Max Unwinding Dia.

|

700mm

|

700mm

|

|

Max Rewinding Dia.

|

700mm

|

700mm

|

|

Dimension(L*W*H)

|

4650* 1100 * 1670mm

|

4650 * 1200 * 1670mm

|

|

Machine Weight

|

About 2500KGS

|

About 3000KGS

|

Detail Images

|

Machine Detail

|

|

|

|

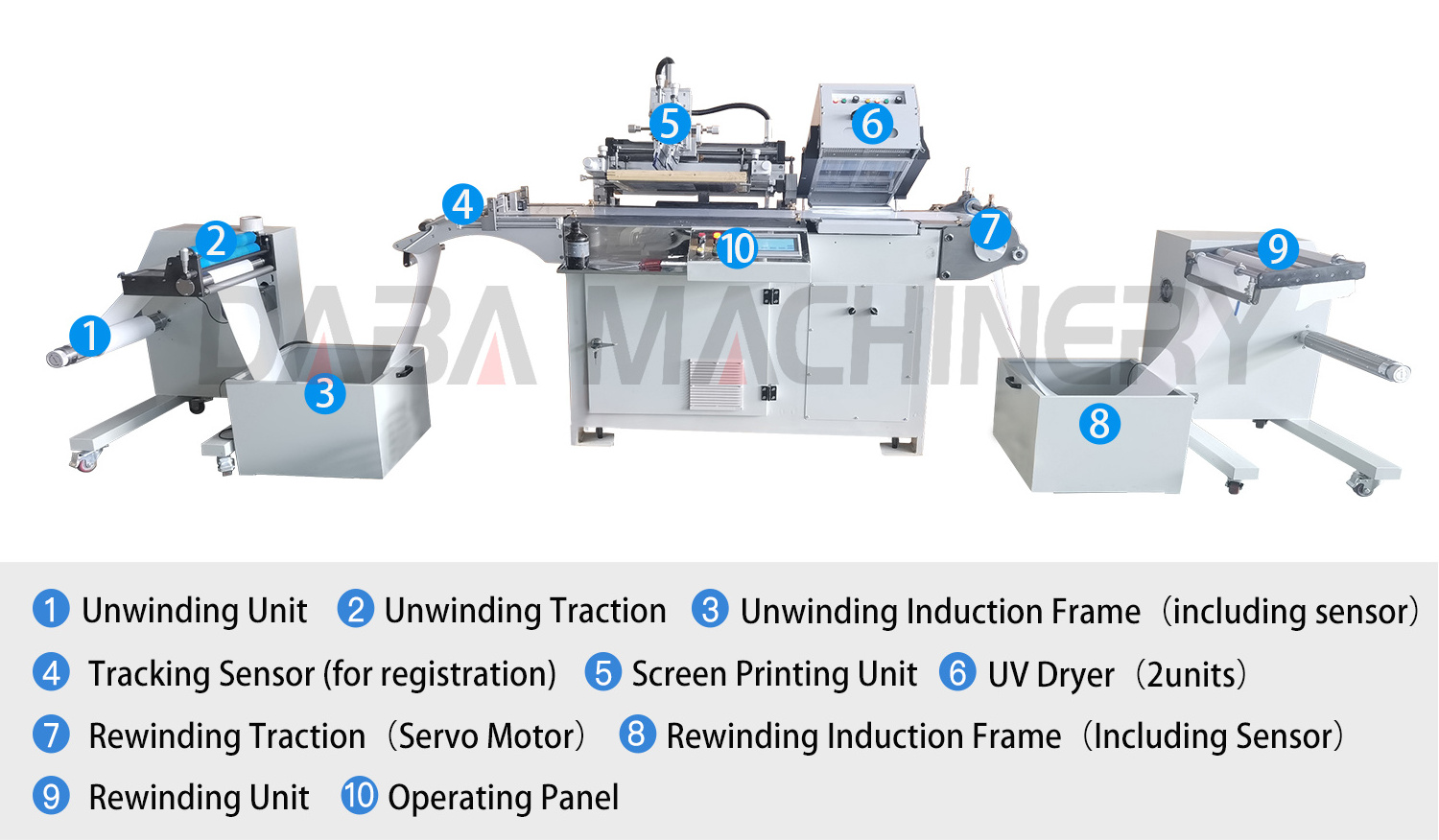

Unwinding Unit

|

1. 3-inch diameter air shaft for loading substrate roll;

|

|

|

|

2. Adopt friction plate tension control;

|

|

|

|

3. Press belt with dust removal device;

|

|

|

|

4. With metal unwinding induction frame, with a sensor for material to automatically feeds the paper;

|

|

|

|

5. With Auto Ending roll sensor, automatic induction of the material shortage and shutdown;

|

|

|

|

6. Electrostatic spray paint on the surface of the fuselage, no easy to rust

|

|

|

Printing Unit

|

1. Using Panasonic high-precision tracking electric eye, 3 colors, suitable for different materials and colors;

|

|

|

|

2. The print head rise and fall vertically for convenient access to screen and squeegee;

|

|

|

|

3. The squeegee and flood bar printing angle and pressure is adjustable to fit different printing tasks;

|

|

|

|

4. Precision linear motion guides are used on horizontal slideway for extremely smooth and stable printing head stroke

|

|

|

|

5. Equipped with 1 set of high-quality aluminum alloy screen frame

|

|

|

Heating Oven

|

1. Equipped the oven with 2 UV lamps to dry the ink at high speed and efficiency;

|

|

|

|

2. The power of each UV lamp is 3.8KW

|

|

|

Traction Unit

|

Feeding traction adopts Japanese Yaskawa servo motor control

|

|

|

Rewinding Unit

|

1. 3-inch diameter air shaft for substrate rolls rewinding;

|

|

|

|

2. Rewinding tension adopt motor control;

|

|

|

|

3. A metal rewinding induction frame with a sensor, automatically rewind the paper;

|

|

Our Service

DABA COMPANY have a specialize and efficiency working team.If you are new onthe printing and packing area Some samples of your products could be shew to uswill be appreicate we will give you specialized suggestion of whole work

2.Shipping Service

DABA COMPANY have a spcialized and independent department which just for shipping the buyer's goods.

DABA COMPANY have a spcialized and independent department which just for shipping the buyer's goods.

The workers are knowing T/T,L/C Items well.All Exporteddocuments could be made perfectly

DABA COMPNAY cooperate with the most famous shipping company in China also.

They could provide the best and economic shipping ways to the buyer's port.

DABA COMPNAY cooperate with the most famous shipping company in China also.

They could provide the best and economic shipping ways to the buyer's port.

3.Installation Services

Installation Services are available with all DABA Company machines.DABA Comapnywill dispatch technician to The Buyer's factory to installation and preoperation of machines But the buyer need to surpply the round trip tickets food hotel cost.

Installation Services are available with all DABA Company machines.DABA Comapnywill dispatch technician to The Buyer's factory to installation and preoperation of machines But the buyer need to surpply the round trip tickets food hotel cost.

4.Clients Training Services

DABA Company advise The buyer could send own technican come to DABA factoryto learn how to operate machines.DABA Company technician will teach and train thelerners hand by hand till he can operate machine by himself.

Obviouslly,Traning within Installation period is acceptable.

DABA Company advise The buyer could send own technican come to DABA factoryto learn how to operate machines.DABA Company technician will teach and train thelerners hand by hand till he can operate machine by himself.

Obviouslly,Traning within Installation period is acceptable.

5.After Sales Service

DABA Company machines guarantee time is one year.

Many easy broken spare parts will be prepared in the tool box together with machines.

DABA Company machines guarantee time is one year.

Many easy broken spare parts will be prepared in the tool box together with machines.

Any parts broken Just a pictures or a videos.The new free parts will reachwithin 3-7 Express working days.

Hot Searches