1) Large reduction ratio cycloidal gear reducer, Omron frequency conversion speed regulation

2) polyurethane wear resistant rubber block

3) Pneumatic comp

ression, through the double pressure regulating valve to adjust the lifting and compression force

4) Omron PLC control

5) Traction speed can b

e adjusted by buttons on the panel, and digital display of line speed indicator

6) Traction clamping range : 500X100mm

7) Power : 3KW

8) Effective traction length : 2000 mm

9) Traction speed : 0.1-1m /min

10) Traction : 150KN

11) The length of traction glue block : 600 mm

12) Traction mode : flat open caterpillar type

13) Overall size : 2500×1300×1450 mm

- Product Details

- {{item.text}}

Quick Details

-

operating voltage:

-

380V&440V/50HZ 3 Phase

-

Air pressure:

-

0.4-0.6Mpa

-

total power:

-

40Kw

-

Coil diameter:

-

Max 40mm

-

Traction speed:

-

0.1-1m/min

-

Cuttin speed:

-

2850rpm

-

Winding speed:

-

9-95rpm

-

Effective track holding length:

-

2500mm

-

Tracking cut stroke:

-

700mm

-

Unit dimensions:

-

20000X1850X1450mm

Quick Details

-

Place of Origin:

-

Henan, China

-

Weight (KG):

-

6500

-

Brand Name:

-

ZHONGSHENG

-

operating voltage:

-

380V&440V/50HZ 3 Phase

-

Air pressure:

-

0.4-0.6Mpa

-

total power:

-

40Kw

-

Coil diameter:

-

Max 40mm

-

Traction speed:

-

0.1-1m/min

-

Cuttin speed:

-

2850rpm

-

Winding speed:

-

9-95rpm

-

Effective track holding length:

-

2500mm

-

Tracking cut stroke:

-

700mm

-

Unit dimensions:

-

20000X1850X1450mm

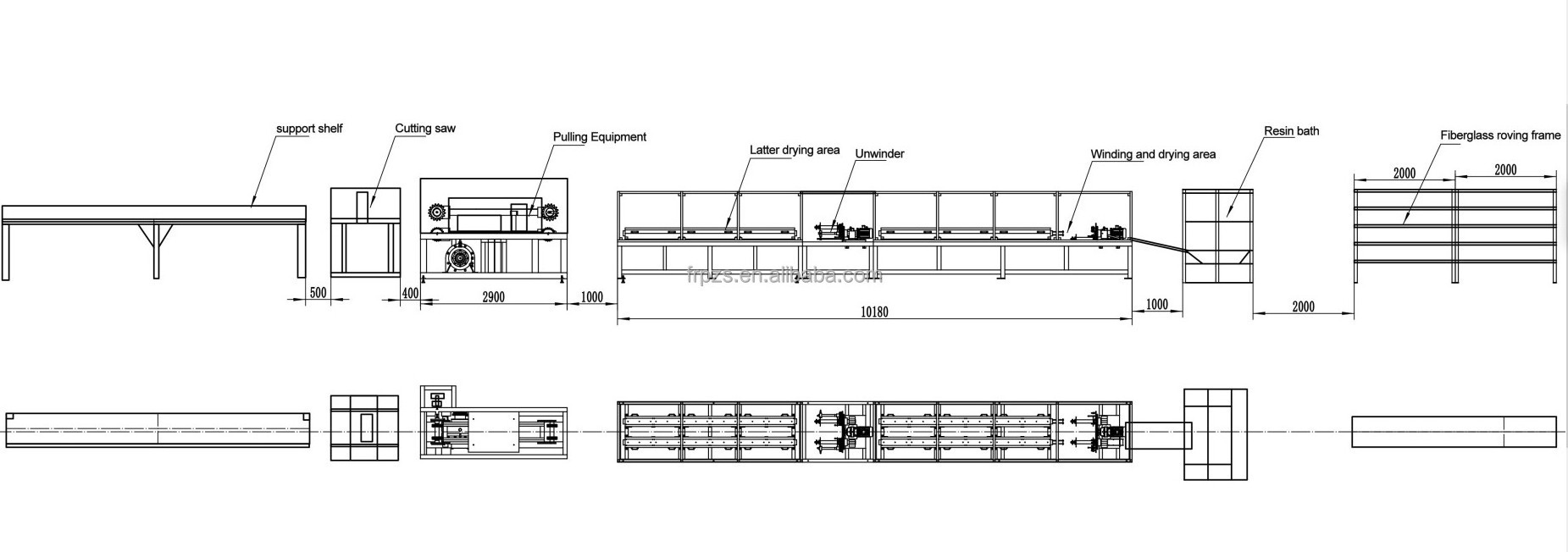

Frp Rebar Production Machine Structure principle

The unit is mainly composed of yarn frame, dipping tank, winding, oven, tractor, cutting saw and stacking device.

1. Yarn frame:

3.winding device: gear drive line roller around the product, winding thread. Adopt frequency conversion speed regulation mode, speed stepless adjustment.

4. Unwinding device:

6. automatic tracking cutting saw:

7. product stacking device:

1. Yarn frame:

place yarn group and adopt steel plate, steel pipe and Angle steel welding structure.

2. dipping tank: made of stainless steel welding, internal yarn pressing roller to make roving fully impregnated in resin.

2. dipping tank: made of stainless steel welding, internal yarn pressing roller to make roving fully impregnated in resin.

3.winding device: gear drive line roller around the product, winding thread. Adopt frequency conversion speed regulation mode, speed stepless adjustment.

4. Unwinding device:

gear drive is adopted to push down the winding belt which is wound to the glass and steel bar to form the thread. Frequency conversion speed regulation is adopted to adjust the speed stepless.

5. oven:

5. oven:

casting aluminum heater, intelligent temperature controller temperature control. The heating box adopts split structure,

which can be convenient Remove dripping resin and fill the interior with thermal insulation.

which can be convenient Remove dripping resin and fill the interior with thermal insulation.

6. automatic tracking cutting saw:

according to the specific requirements of the production line of glass and steel line fixed length cutting.

7. product stacking device:

FRP REBAR after cutting stacking, by the production personnel to take away

|

Technical parameters

|

|

|

|

|

||||

|

operating voltage

|

380V & 440V /50HZ

|

Air pressure

|

0.4-0.6Mpa

|

|

total power

|

40Kw

|

center height

|

1000mm

|

|

Winding Numbers

|

2

|

Center distance of winding head

|

411mm

|

|

Winding speed

|

9-95rpm

|

Coil diameter

|

Max 40mm

|

|

Traction speed

|

0.1-1m/min

|

The traction

|

Max100Kn

|

|

Effective track holding length

|

2500mm

|

Track clamp width

|

600mm

|

|

Cutting range

|

(W X H)600X65mm

|

Cuttin speed

|

2850rpm

|

|

Tracking cut stroke

|

700mm

|

Fixed-length

|

travel switch

|

|

Unit dimensions

|

20000X1850X1450mm

|

|

|

frp rebar machine layout

Technical parameters of components of fiberglass equipment

yarn 2000×600×2000mm 3 UNITS

Resin tank one layer 1 UNIT

Oven (including winding device, unwinding device)

6 meters 1 UNIT

1) Double head heating 12 sections in total

2) FRP rebar production range: maximum ф 30mm

3) Heating ring: 48 pieces

4) Power: 33.6KW

5) Overall size: 9130x1400X850mm

6) Speed: frequency conversion speed regulation

2) FRP rebar production range: maximum ф 30mm

3) Heating ring: 48 pieces

4) Power: 33.6KW

5) Overall size: 9130x1400X850mm

6) Speed: frequency conversion speed regulation

Tractor 1 unit

Automatic cutting saw

1) Cutting power : 3KW

2) Vacuum power, water and dust removal

3) The maximum cutting section size : 600X100mm

4) Saw blade speed : 1400r/min

5) Saw blade diameter : φ300/φ50

6) Cuttin g mode automatic/manual

7) Track cut ting stroke : 700 mm

8) Exterior size : 1850×1250×1510 mm

2) Vacuum power, water and dust removal

3) The maximum cutting section size : 600X100mm

4) Saw blade speed : 1400r/min

5) Saw blade diameter : φ300/φ50

6) Cuttin g mode automatic/manual

7) Track cut ting stroke : 700 mm

8) Exterior size : 1850×1250×1510 mm

Packing and transportation

Hot Searches