- Product Details

- {{item.text}}

Quick Details

-

Frequency:

-

50HZ/60HZ

-

Welding Area:

-

any

-

Dimensions:

-

320*165*205mm, 320(L)*165(W)*205(H)mm

-

Usage:

-

Plastic Welding, geomembrane welding

-

Weight (KG):

-

9 KG

-

Power (kW):

-

800w

-

Volt:

-

220V

-

Certification:

-

ISO9001

-

welding thickness:

-

0.1-1mm

-

Engine:

-

electrical machinery

-

weight:

-

5KGS

-

Power:

-

800W

-

Local Service Location:

-

None

-

Showroom Location:

-

None

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

none

-

Voltage:

-

220V/380V

-

Frequency:

-

50HZ/60HZ

-

Welding Area:

-

any

-

Dimensions:

-

320*165*205mm, 320(L)*165(W)*205(H)mm

-

Usage:

-

Plastic Welding, geomembrane welding

-

Weight (KG):

-

9 KG

-

Power (kW):

-

800w

-

Volt:

-

220V

-

Certification:

-

ISO9001

-

welding thickness:

-

0.1-1mm

-

Engine:

-

electrical machinery

-

weight:

-

5KGS

-

Power:

-

800W

-

Local Service Location:

-

None

-

Showroom Location:

-

None

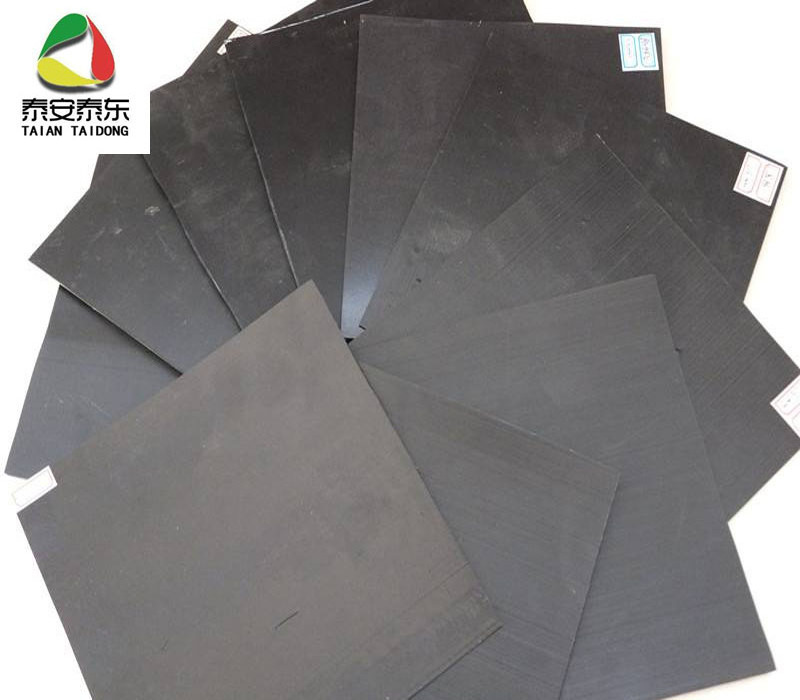

HDPE geomembrane welding machine

Electric machine carried with above and below pressure wheel and turn it through speed-slow box and chain steel, and heating the bracket up and turn thermal wedge to plug in between the two main materials, meantime let the pressure bracket press the pressure wheel to made the thermal-fused mother material together. The picture is as follow:

Operating Criterion

Notice: In order to obtain the excellent quality and high efficiency, it should be manipulated by professional people since the welding quality of the machine has direct relationship with the enactment of speed and temperature.

- The user must choose to the three holes receptacle with earthing and confirm the good connection of exterior wire. Pick the pressure handle up to separate the up and down iron wheels and then plug the power supply on.

- Switch power supply on, and choose suitable temperature (Temperature adjusting diagram – literature) and speed,. Then pick some narrow material to weld for a try and make sure the best effect. Owing to the difference between the environmental temperature and the thickness of material, the welding temperature of the same material could be different. We can choose to a referenced speed (about 1.5m/min) when select the temperature. And then slowly adjust the temperature from low to high.(about from 250’ C to 400’C)

- The estimation of the welding temperature: it can be directly watched the transparence PE material .If the welding mark is lever-off with transparence glass status, it showed that the temperature and the speed is suitable ;if the welding mark is seriously broken up, it showed that the temperature is too high or the speed is too low; If the welding mark is not transparence with white status, it showed that the temperature is on the slow side or the speed is on the fast side .And to the non transparence material ,it also can be tested by resistance pull after the whole party is cooled down .

- Mending the edge of the welding material smooth .The surface face to the front side, and overlap to left down and right up .The width of pulled up is 120mm.

- Plug the welding material between the two iron wheels to make the parallel between the body of the machine and the edge of mother material, and it can weld itself after confirmed the temperature and the speed. Usually the operator just watch the warp between the welding mark and the edge of the mother material and timely rectify it within a small scope .At the end of material welding, pick up the handle to separate the up and down iron wheels.

- Owing to the thermal inertial, it can adjust the temperature within small scope to offset the discrepancy in temperature if it comes too high or too low in the process of welding.

- In the process of welding, it can adjust through the two interior hexangular screw on the swaying head if the welding mark is not equality in two outside. (Just the corresponding screw in the upside of intensive welding deep or in the upside of loosen welding mark shadow)

- Welded material crossed with another material in the shape of “T”. The ways of welding is as the diagram below. Cut the crossing head sticking to the thermal wedge off 12cm inclin ed.

Summarize

They can weld geo-membrane of various thickness and are applicable for welding of all thermal-fused material such as LDPE, PVC, HDPE, EVA, PP and PVC , HDPE , EVA , PP

The control of this series adopt PID automatic thermostatic control with high control and low temperature fluctuation. Speed control of this series adopt PWM automatic voltage and regulation speed circuit. Direct current servo the motor drive with great output torque and staple performance in walking. It can maintain a constant speed on the condition of creeping, vertical creeping and road load. Also this series of welding machine are stable in performance despite of external temperature and voltage variation.

This series of welding machine is excellent in performance and easy for operating, with high welding speed and good work quality. It is extensively used in engineering projects such as expressways, tunnels, reservoirs, waterproof of construction and so on.

1.Output Voltage : 220V Frequency : 50Hz

2. Power : 1800W

3. Welding speed : 0.4~5m/min

4.The temperature of Heating up : 0~450 ℃

5. The thickness of welding material : 1mm~4mm(Single membrane thickness)

6. Welding width : 14mm×2 I nterior C avity :16mm

7. Welding intensit y ≥85%Maternity material ( Resistance to the direction of cutting )

8. Joint width : 120mm

9.Machine body weight : 13kg