- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5490x3875x5530mm

-

Weight:

-

80 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

coal mill pulverizer vertical Raymond Mill Manufacturer

-

Keywords:

-

coal mill pulverizer vertical Raymond Mill Manufacturer

-

The Machines classification:

-

Mineral Milling Machines

-

After sale service:

-

Engineers available to service machinery overseas

-

Feeding size:

-

30mm

-

Delivery:

-

40 days

-

Spare parts supplying:

-

Life Long Provide

-

Certification:

-

ISO CE

-

Output size:

-

0.18-0.038mm (80-400 mesh)

Quick Details

-

Capacity(t/h):

-

6-25

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

HongCheng

-

Dimension(L*W*H):

-

5490x3875x5530mm

-

Weight:

-

80 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

coal mill pulverizer vertical Raymond Mill Manufacturer

-

Keywords:

-

coal mill pulverizer vertical Raymond Mill Manufacturer

-

The Machines classification:

-

Mineral Milling Machines

-

After sale service:

-

Engineers available to service machinery overseas

-

Feeding size:

-

30mm

-

Delivery:

-

40 days

-

Spare parts supplying:

-

Life Long Provide

-

Certification:

-

ISO CE

-

Output size:

-

0.18-0.038mm (80-400 mesh)

Limestone Graphite Dolomite fly ash Calcite carbon black Raymond Mill Manufacturer

Raymond Roller Mill Overview

Raymond roller mill is a particular milling equipment to process minerals into fine powder, it has excellent characteristics of dependability and economy in maintenance especially in medium fine and fine powder processing. The mill equipped with automatic and dustless system for high working efficiency, it is able to grinding and classifying mineral ores between 0.18-0.038mm fineness in high degree of uniformity.

Hcmilling (Guilin Hongcheng) has rich experience in manufacturing grinding mills, o ur Raymond roller mill is tested at various levels by the team of experts that assures its high quality and performance. We have a group of experts that includes senior engineers, technicians, workers etc ., t hey are known for their dedication and expertise in their domain. All the testing takes place under their supervision that assures the superior quality of our products.

Applicable materials

The mill can process a variety of Non-flammable and explosive nonmetal materials with Mohs hardness under 7 and moisture under 6%, such as bauxite, feldspar, fluorite, , ilmenite, phosphorite, clay, graphite, kaolin, diabase, gangue, wollastonite, quick lime, silicon carbide,bentonite, manganese, natural sulfur, pyrite, crystal, corundum, kyanite, evening stone, andalusite, wollastonite, sodium saltpeter, talc, asbestos, blue asbestos, mica, etc.

Raymond roller mill has a high level of grinding efficiency combined with reduced energy consumption, this mill is an excellent milling solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality. Further, it can dry, grind and separate within a single unit, powder fineness range from 0.18-0.038mm and it is manageable as customers’ requirements.

The newly developed classifier and the roller mill combines perfectly for the production of fine and medium fine powders. The innovative rotor design reduces energy consumption without losing its ability to produce sharp cut points. The application industries including building materials, metallurgy, cement, chemical industry, refractories, pharmaceuticals, and crushing and grinding of mines. Applicable materials including non-metallic minerals with Mohs hardness below 7 and humidity within 6%.

Model: HC1700

[Feeding size: ]: 0-30mm

[grinding material moisture]: <5%

[Product moisture]: ≤1-6%

[Capacity]:

6-25

t/h

[Fineness]: 0.18-0.038mm

[ Diverse Application]:The final powder can be used in the building materials, chemicals, metallurgy, coatings, papermaking, rubber, medicine, food, and many other industries.

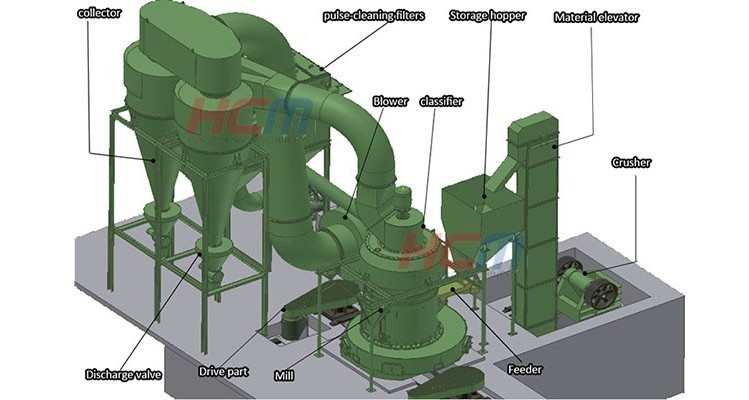

Process Flow Diagram

HC Series Roller Mill Technical Parameters

|

Model |

Roller Amount |

Ring Inner Diameter (mm) |

Max Feeding size (mm) |

Fineness (mm) |

Capacity (t/h) |

Total Power (kw) |

Weight (t) |

Overall Dimension (mm) |

|

HC1000 |

3 |

1000 |

≤25 |

0.022-0.18 |

1-6.5 |

85/101 |

14 |

8200×5800×10580 |

|

HC1300 |

4 |

1300 |

≤30 |

0.038-0.18 |

2-12 |

165/180 |

28 |

10800×10300×7800 |

|

HC1500 |

4 |

1500 |

≤30 |

0.038-0.18 |

3-15 |

242 |

38 |

12072×6558×9929 |

|

HC1700T |

5 |

1700 |

≤30 |

0.038-0.18 |

5-20 |

264-314 |

38 |

12072×6558×9929 |

|

HC1700 |

5 |

1700 |

≤30 |

0.038-0.18 |

6-25 |

342-362 |

38 |

12072×6558×9929 |

High-tech system and pass-through rate

The Raymond roller mill takes a small area than ball mill and integrates raw materials processing to powder making and packaging into one unit, it can form an independent production system. The finished powder has even fineness and high pass-through rate.

Smooth transmission and high wear resistance

The transmission device of the machine adopts a hermetic gear box and belt wheels, with stable transmission and reliable operation. The core components use high-performance wear-resistant materials with high wear resistance and cost savings.

Ease of operation and maintenance

Using a centralized control electrical system, the workshop can basically realize automatic operation. The electromagnetic vibrating feeder is used for feeding, which is continuous and uniform, easy to adjust, fuel-saving and power-saving, and easy to maintain.

High capacity

Optimized configuration of pipes and fan systems, reducing wind resistance and pipe wall wear, dynamic turbine classifier for high throughput and improved fineness control.

Maximum wear characteristics

Hard surfaced overlaid, grinding rolls for improved performance and excellent wear. Through automatic operation it is possible to save power, grinding media, and liner wear, while increasing capacity.