- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.1%

-

CrO Content (%):

-

0.01

-

SiC Content (%):

-

88

-

Place of Origin:

-

Henan, China

-

Model Number:

-

RON

-

Brand Name:

-

Lite

-

Product name:

-

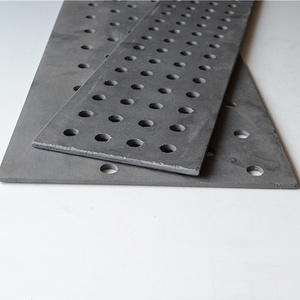

Reaction sintered silicon carbide beam/batts as kiln furniture

-

raw material:

-

Silicon carbide powder

-

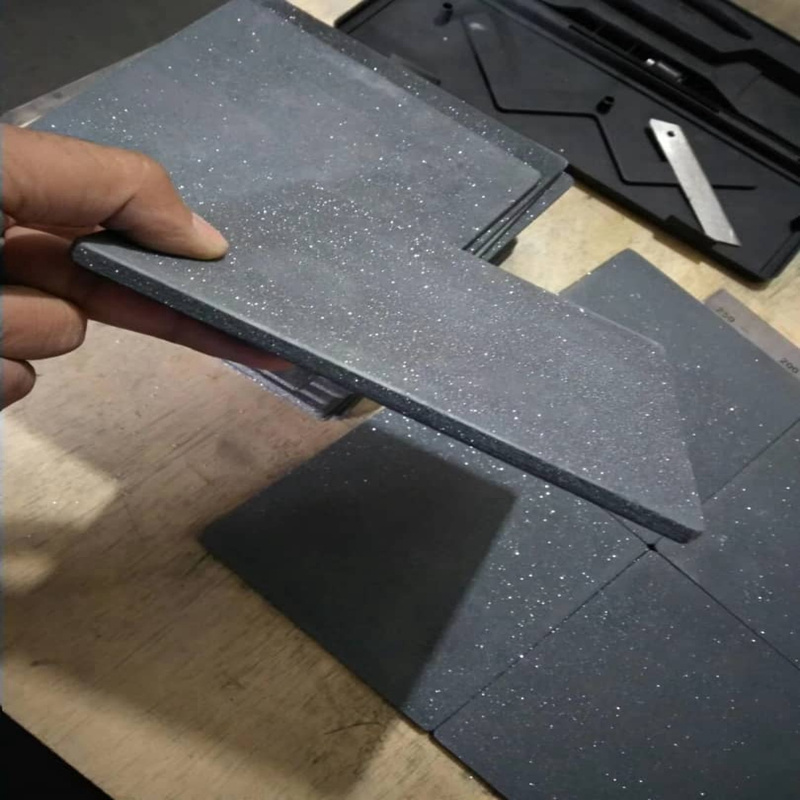

Color:

-

black

-

Feature:

-

Good thermal shock resistance

-

Density:

-

2.8g/cm3

-

apparent porosity:

-

12%

-

max working temperature:

-

1450℃

-

Usage:

-

kiln car of Ceramic kiln

-

Certificate:

-

test report

Quick Details

-

SiO2 Content (%):

-

5%

-

Al2O3 Content (%):

-

1%

-

MgO Content (%):

-

0.02%

-

CaO Content (%):

-

0.1%

-

CrO Content (%):

-

0.01

-

SiC Content (%):

-

88

-

Place of Origin:

-

Henan, China

-

Model Number:

-

RON

-

Brand Name:

-

Lite

-

Product name:

-

Reaction sintered silicon carbide beam/batts as kiln furniture

-

raw material:

-

Silicon carbide powder

-

Color:

-

black

-

Feature:

-

Good thermal shock resistance

-

Density:

-

2.8g/cm3

-

apparent porosity:

-

12%

-

max working temperature:

-

1450℃

-

Usage:

-

kiln car of Ceramic kiln

-

Certificate:

-

test report

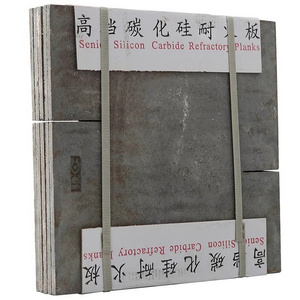

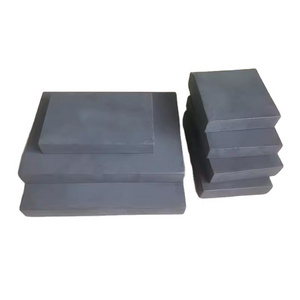

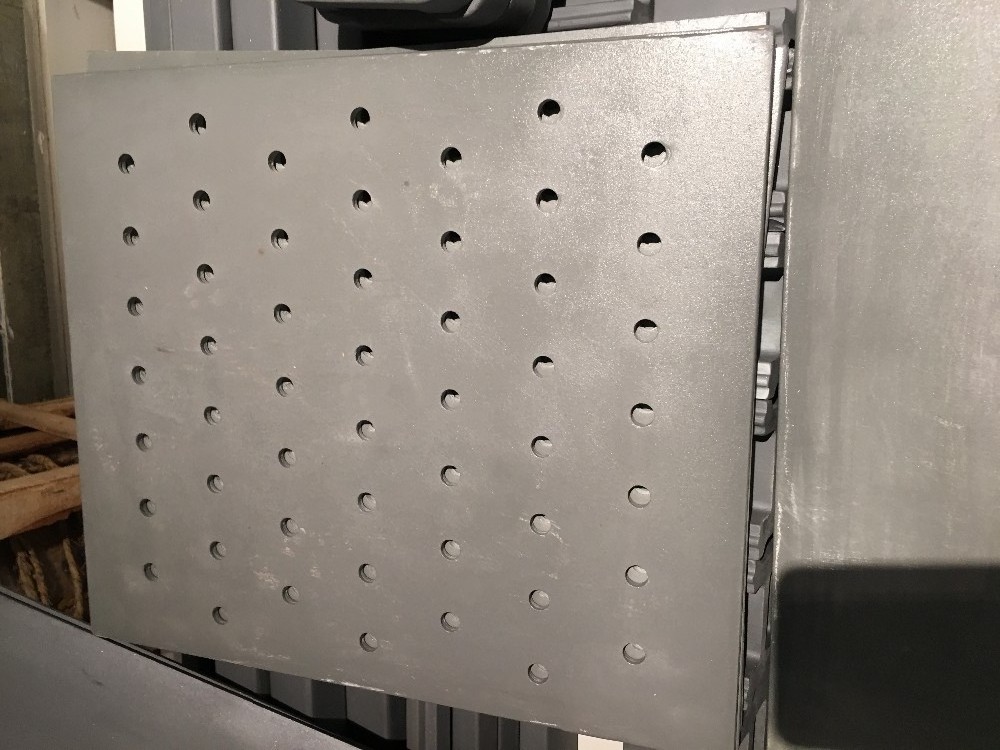

Oxidation firing nitride bonded Silicon carbide plate/ ceramic kiln shelf/SiC batt

Product description

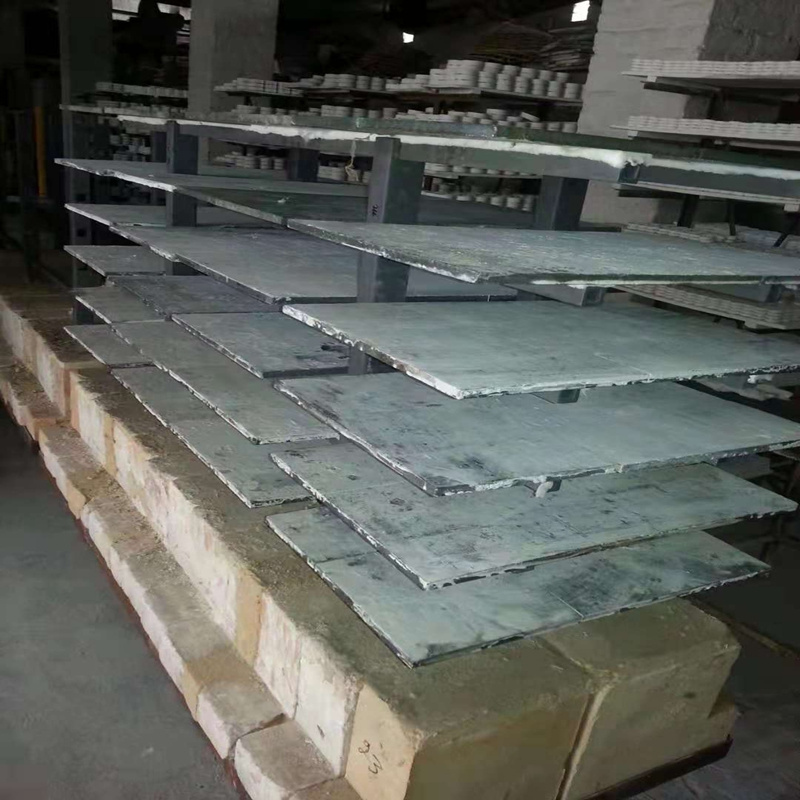

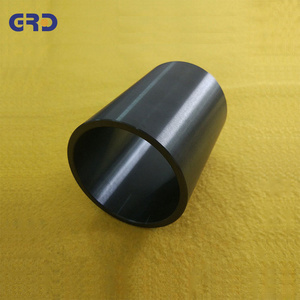

The material of siliconized silicon carbide has series of basic superiority and characteristic such as high strength,extreme hardness,wear resistance,high temperature tolerance,corrosion resistance, oxidation resistance thermal shock resistance,high thermal conductivity,low coefficient of thermal expansion,creep resistance under high temperature and so on.Many products can be made from it such as beams,rollers,cooling air pipes,thermal couple protection tubes,temperature-measuring tubes,sealing parts,and special shaped parts.

Parameter

| Properites | Units | Silicon carbide Material | ||||

| Type | SiC | SiSiC | NSiC | RSiC | ||

|

Chemical composition |

SiC% | 89 | 87 | 92 | 70 | 99 |

| SiO2 % | 5 | 6 | - | Si3N4 28 | - | |

| Al2O3% | 1 | 2 | - | - | - | |

| Bulk Desity | g/cm3 | 2.85 | 2.8 | 3.01 | 2.8 | 2.75 |

| Apparent porosity | % | 12 | 14 | 0.1 | 12 | 14 |

| M.O.R.@20℃ | MPa | 50 | 48 | 260 | 180 | 100 |

| M.O.R.@1300℃ | MPa | 58 | 56 | 280 | 185 | 120 |

| C.T.E.@20℃-1000℃ | 10-6K-1 | 4.8 | 4.2 | 4.5 | 4.7 | 4.6 |

| C.C.S | MPa | 100 | 90 | 900 | 500 | 300 |

|

Max working temperature |

℃ | 1450 | 1420 | 1300 | 1500 | 1650 |

| application |

Used in ceramic shuttle kiln, tunnel kiln and roller kiln, Kiln furniture. |

|||||

Feature

• Excellent energy savings.

• Lighter weight and higher load capacity.

• Excellent distortion resistance at high temperature.

• High thermal conductivity

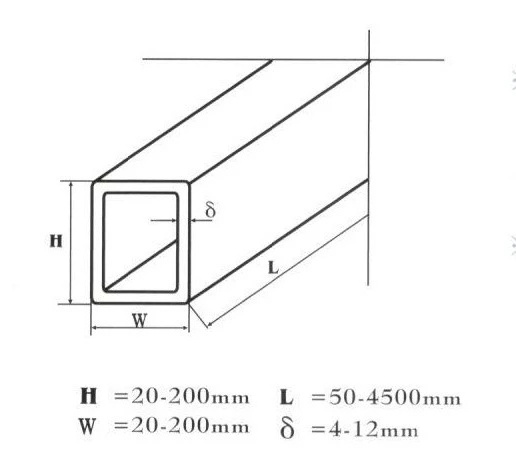

Dimension of beam

Application

RBSiC(SiSiC)cross Beams are used for the loading structure systems of tunnel kilns,shuttle kilns and many

other industrial kilns. RBSiC(SiSiC)cross beams have higher strength and there are no deformations even in very high temperature.

And also the beams display long operational life.The beams are the most suitable kiln furniture for sanitarywear

and electrical porcelain applications.RBSiC(SiSiC)has excellent thermal conductivity,so it is available to save energy with less weight of the kiln car.

• sanitary ware

• Kiln furniture crucibles

• glass panel industries

• Sliding bearings

• glost firing of tableware.

• Heat exchangers

• Burners

• Wear parts (thread guides)

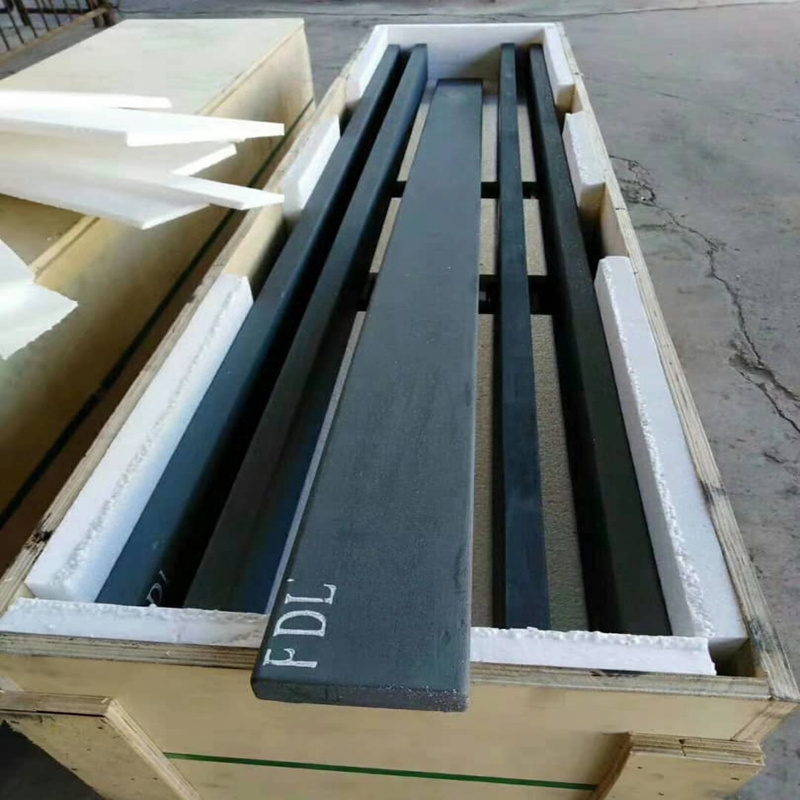

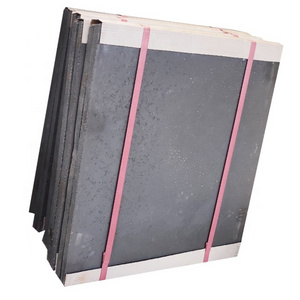

Packing and shipping

Packing detail

1.50 pieces in a wooden box (fully enclosed, safe and secure)

2.800kg~1000kg /wooden box.

3.Anti-collision protection such as foam board

4.3-layer wood composite panel, sturdy, impact resistant, drop resistant

Shipping detail

1.Professional car transport to various ports in China, then loaded by a professional shipping company.

2.Both FOB and CIF can be operated flexibly.

3. Competitive sea freight and short transit time.

Why choose us

1. High quality: Strict quality control and more than 10 years experiences.

2. Competitive price: Directly from our factory to your hands without other traders.

3. Good packaging: Avoid damage and secure your goods in transportation.

4. Quick response: Your any questions will be replied within 24 hours.

5. Professional technology: The size, density, chemical composition can be customized.

6. Geographical advantage: Our factory is located in Zhengzhou Henan province, which is one of the main refractory production bases in China. we have abundant resources and high quality minerals. This favorable condition reduce the cost to save you money.

7. Timely delivery: 25 days after receiving deposit.

8. Samples are free.

Company profile

Henan LiTe Refractory Material Co.,Ltd is located in Zhengzhou Henan province, which is one of the main refractory production bases in China, specialized in refractory manufacture, Engineering Construction, Also new technology research & popularization and application for high temperature industrial furnace. The company possess the independent import & export certification, service the customers domestic & worldwide. Developed to be the technological manufacturer and service-type enterprise in the field of refractory for furnace engineering and technology.