Name:

Vacuum Stript Casting Furnace

The process is to mix all raw materials ( Rare earth, Iron...), and melt to pieces

Basic Parameters

|

Production Name

|

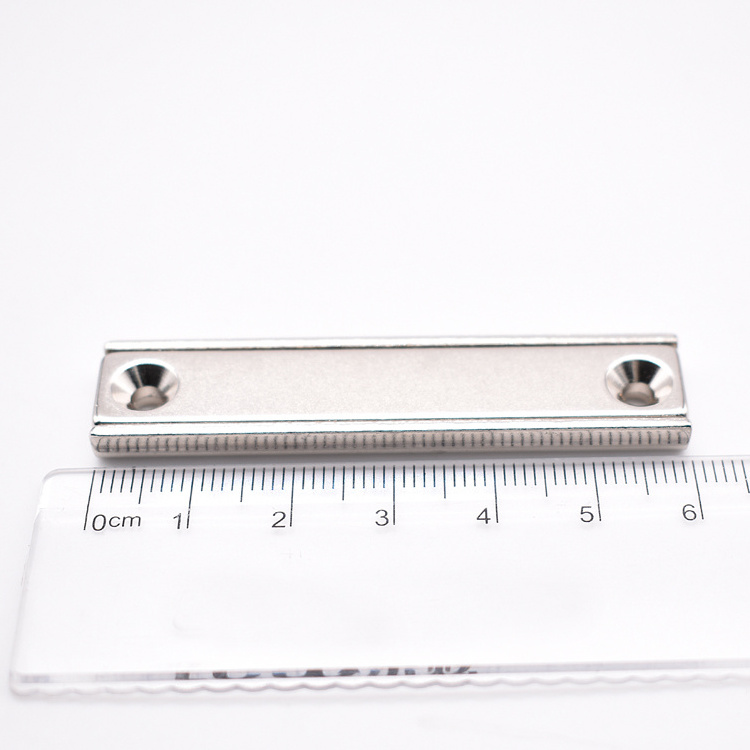

N52 Neodymium Custom Pot Magnets

|

|

Magnet Dimension

|

60 x 13.5 x 5mm

|

|

Magnetized Direction

|

5mm

|

|

pull force

|

30kg /66lbs

|

|

Max. Working Temperature

|

180℃

|

|

Material

|

Ndfeb Magnet + Steel shield

|

|

Magnet Dimension

|

Custom dimension is available

|

|

Magnetized Direction

|

While ordering, please indicate magnetized direction

|

|

Magnet Grade

|

We can offer all NdFeB Magnet grades,

Example: N35,N42,N52, N45SH,N42UH...

If you are not sure which grade is proper, contact our engineer freely.

|

|

Temperature Resistance

|

Temperature

is the first factor you have consider while choosing a magnet, please contact our engineer for details.

|

|

Coating

|

Other coatings availalbe

Example: NiCuNi, Zinc, Epoxy, Gold surface, ..

|

|

MOQ

|

No MOQ.

Free Samples are available.

|

*

Temperature Resistance

– Temperature is the first factor you have consider while choosing a magnet, to make sure you choose a proper magnet, you can refer to this sheet or contact our engineer for details.

|

Magnet Series

|

Max. Working temperature

|

Magnet grade

|

|

N

|

≤80℃/176°F

|

N33,N35,N38,N40,N42,N45,N48,N50,N52,

|

|

M

|

≤100℃/212°F

|

N35M,N38M,N40M,N42M,N45M,N48M,N50M,N52M

|

|

H

|

≤120℃/248°F

|

N35H,N38H,N40H,N42H,N45H,N48H,N50H

|

|

SH

|

≤150℃/302°F

|

N35SH,N38SH,N40SH,N42SH,N45SH,N48SH

|

|

UH

|

≤180℃/356°F

|

N28UH,N30UH,N33UH,N35UH,N38UH,N40UH,N42UH,N45UH

|

|

EH

|

≤200℃/392°F

|

N28EH,N30EH,N33EH,N35EH,N38EH,N40EH,N42EH

|

|

AH

|

≤230℃/446°F

|

N28AH,N30AH,N33AH,N35AH,N38AH,N40AH

|

* Premium Quality Coating – This NdFeB Magnet are protected with a corrosion resistant NiCuNi coating to create a high quality silver look that doesn't rust or scratch. NiCuNi coating is one of the very popular surface treatment of NdFeB Magnets. Definitely other coatings are available at ND MAGS. Like NiCuNi,Epoxy, Zinc, Gold, Everlube

*

Powerful Magnets

- Made of Strongest NdFeb Materials, which is called " Magnet King", Strong Holding Power. If you need the small size magnet that has to produce strongest power, The NdFeB Magnets are probably your first choice. The following sheet is about all magnet grades we can offer to customers

Here is some of comments from our world-wide customers.

You can check all the comments at our company profile

[ TRUST YOU WILL LIKE OUR SERVICES, QUALITY AND PRICE ]

Name:

Vacuum Stript Casting Furnace

The process is to mix all raw materials ( Rare earth, Iron...), and melt to pieces

Name:

Magnetic pressing Machine

Process:

Magnet pressing and Orientation

The magnetic powder is shaped and oriented at this process. The magntic direction is defined now. but now the magnet is without any magnetism.

Name:

Vacuum Sintering Furnace

Process:

Sintering

After pressing, the density of the magnets are still very low. Thus sintering is essential to enhance the magnet density to the standards.

Name:

Auto Electrical Plating Line

When the magnet is sintered, the magnetic properties are fixed that we will inspect the properties. Then the magnets will sent to be machined into customized shapes. Finally all the magnets will be coated to avoid rusted. The poplular coatings are NiCuNi, Epoxy, Zinc ...

Ans: YES, we provide free samples. Contact our engineers for free samples now.

Q2: Can I print logo on the magnets?

Ans: YES, We can help to print logo or marks on the magnets.

Q3: How fast can I get a reply?

Ans:You will receive our reply within 15 minutes during our work time 08:00-21:00(UTC-8).

Q4: Can I get custom-made package for my magnets?

Ans: YES, Just specify your demands to our engineers

Q5: What's your Payment terms?

Ans: We accept Payal, West Union, Credit cards T/T deposit, L/C at sight. OA terms.

Q6: Do you have any instant chat tools?

Ans: Yes.