- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

2mm

-

Voltage:

-

380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

EQS

-

Dimension(L*W*H):

-

4030*3100*2850mm

-

Weight:

-

9500 KG

-

Washing Heads:

-

40

-

Filling Heads:

-

40

-

Capping Heads:

-

12

-

Available Bottle Diameter:

-

50~90mm

-

Available Bottle Height:

-

180~310mm

-

Sterile Air Consumption:

-

0.3M3/Min (0.4-0.6Mpa)

-

CO2 Consumption:

-

18G/100L

-

Blowing:

-

0.6M3/H

-

Feature:

-

High Efficiency

-

Function:

-

Filing

Quick Details

-

Machinery Capacity:

-

15000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Carbonated Drink

-

Filling Accuracy:

-

2mm

-

Voltage:

-

380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

EQS

-

Dimension(L*W*H):

-

4030*3100*2850mm

-

Weight:

-

9500 KG

-

Washing Heads:

-

40

-

Filling Heads:

-

40

-

Capping Heads:

-

12

-

Available Bottle Diameter:

-

50~90mm

-

Available Bottle Height:

-

180~310mm

-

Sterile Air Consumption:

-

0.3M3/Min (0.4-0.6Mpa)

-

CO2 Consumption:

-

18G/100L

-

Blowing:

-

0.6M3/H

-

Feature:

-

High Efficiency

-

Function:

-

Filing

Product Overview

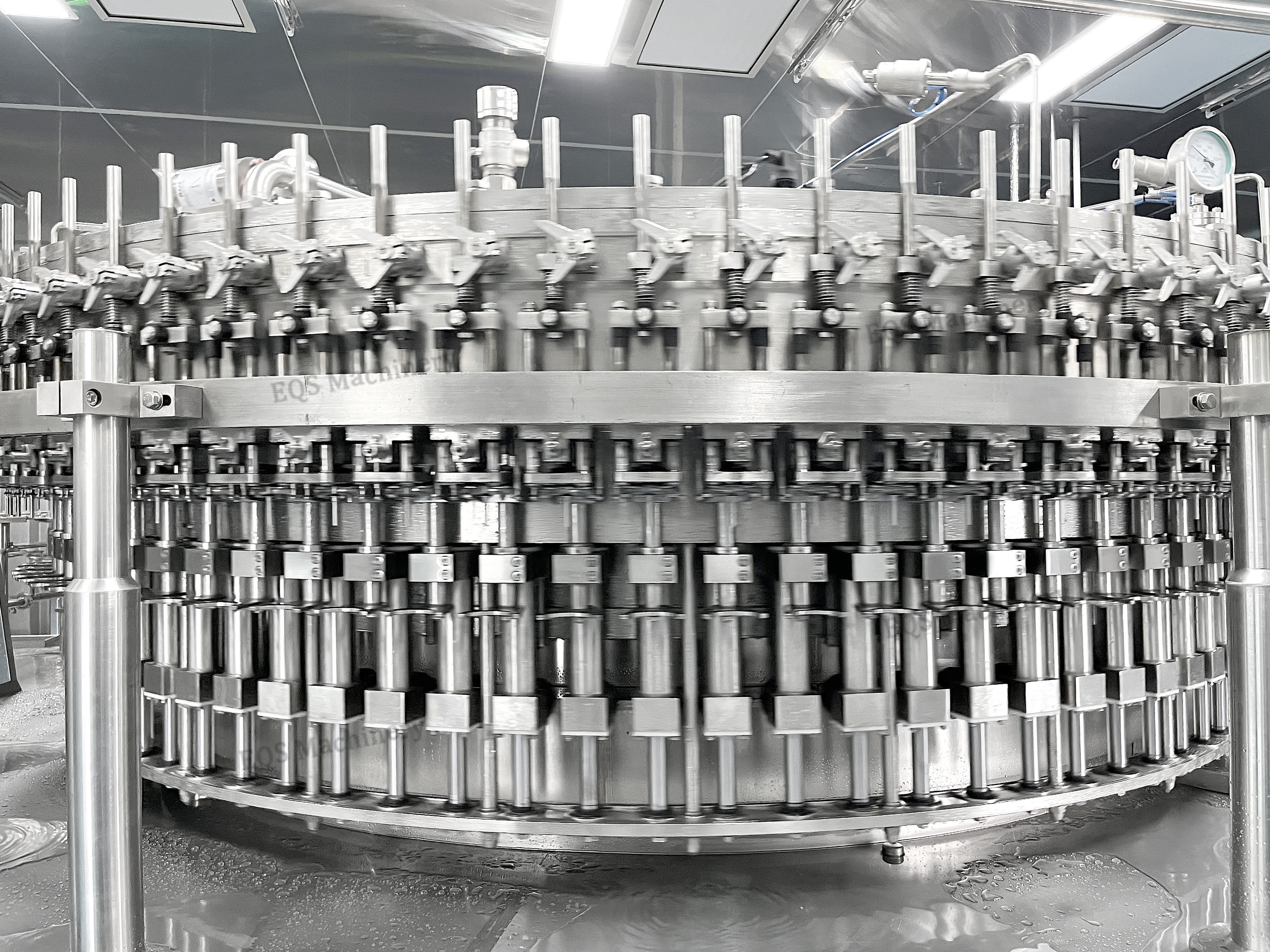

Fully Automatic PET Bottle Carbonated Soft Drinks Making Filling Machine

The DCGF Series is for the carbonated drink 3 In 1 Mono-block Filling Machine. It realizes the rinsing bottle, filling bottle and capping in a unit machine with complete automation. The

carbonated drinks making machine

is designed and manufactured by Italian technology, and the capping machine is adopted with the most advanced French "ZALKIN " capping machine technology, and improved by our domestic famous university’s professor and engineers together.The main machine adopts the advanced PLC control, and the key electrical elements are with abroad famous brand. Such as: SIEMENS, SCHNEDIER, MITSUBISHI, OMRON, AUTONICS, ...

Product Description

1.

This

carbonated drinks making machine

can realize automatic washing and filling and capping function in united machine.

2.The bottle type is for PET bottle and plastic screw cap. And the available bottle volume can be 200ml, 330ml, 500ml, 750ml,... It can be several kinds of bottle size to share- use a same filling machine via change parts. Please keep the same diameter of bottle mouth. 3. Its rated capacity is 15000BPH for 500ml PET bottle.

2.The bottle type is for PET bottle and plastic screw cap. And the available bottle volume can be 200ml, 330ml, 500ml, 750ml,... It can be several kinds of bottle size to share- use a same filling machine via change parts. Please keep the same diameter of bottle mouth. 3. Its rated capacity is 15000BPH for 500ml PET bottle.

Filling Part of Carbonated Drinks Making Machine

The filling method is the isobaric type with stable running performance.

Capping Part of Carbonated Drinks Making Machine

It's for plastic screw cap, the capping part will be customized according to client's cap samples.

More Production Capacity for Choice

Detailed Technical Data of

Carbonated Drinks Making Machine

Learn about related products by clicking

Other Equipment of

Complete

Soda Bottle Filling Machine

for reference

RO Water Treatment System

High Speed CO2 Carbonation Machine

Water Chiller

CIP System

.

Bottle Warmer Tunnel

Bottle Dryer

Self-adhesive Labeling Machine

Operation Table

Laser Printer

After-Sales Service

1.Quality Warranty.

12 months. During the 12 months’ maintenance period, for the problem that caused by our design, manufacture and the material quality, we are responsible for offering the relevant parts and effective services for free for above reason. We will offer a widely and favorable technical support, after-sales service all the time after guarantee period.

2.Installation.

After the equipment arrived at the customer’s site, our technician will install and test the machines, to make sure all the equipment can run properly. The buyer pays for travel expenses, such as visa fee, round trip tickets, ground transportation, meals, hotels and any other expenses related to installation and training at customers’ facility. Besides, the buyer can send staff to our company for learning.

3.Training.

The training content includes the structure and maintenance of the equipment, control and operation of the equipment. Through training, users' technical staff can grasp and the skill of operation and maintenance proficiently, and deal with the general troubles in time. We will appoint qualified technical staff for the guidance.

4. For quality promise.

All material and equipment 's configurations will keep the same as signed contract and PI. All machines will be run a certain times for testing the machine's running performance and pass the factory's quality team's checking. And before delivery the time, we'll also invite the client to attend our for factory test acceptance or client's quality checker before delivery. We promise all machines will be tested well before arriving to client's factory.

Why Choose Us

*

High level humanized customization service to customize the most suitable products and services for you individually according to your specific needs, budget and actual situation.

* Through more than ten years of experience in mechanical production and investigation of customer feedback, we constantly improve products, improve product details and improve machine quality in the spirit of ingenuity. Each unique design is designed to ensure the best user experience for customers.

* Absolute real material and unique design greatly increase the service life of the machine, ensure the stable output of the

machine and long-term efficient working ability.

* Absolute real material and unique design greatly increase the service life of the machine, ensure the stable output of the

machine and long-term efficient working ability.

Value Added

1). Automatic Frequency Step less Speed Adjustment.

2). Complete Set of CIP Clean Connection Ports.

3). Security Function, machine stops when open the window (Option).

Hot Searches