- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

HEB

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

8*1.5*1.6M

-

Weight:

-

5000 kg

-

Product name:

-

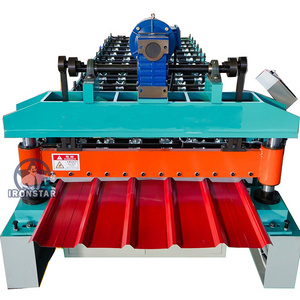

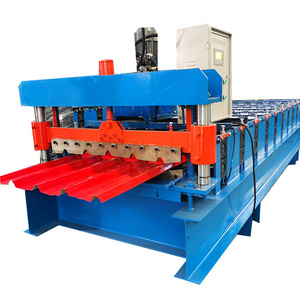

Roof Sheet Forming Machine

-

After-sales Service Provided:

-

Engineers

-

Name:

-

Accessary Roll Forming Machine

-

Usage:

-

Steel Construction

-

Raw material:

-

PPGI

-

Roller material:

-

45#steel Chrome Plated

-

Thickness:

-

0.3-0.8mm Thickness

-

Function:

-

Roof Usage

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

30 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

HEB

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

8*1.5*1.6M

-

Weight:

-

5000 kg

-

Product name:

-

Roof Sheet Forming Machine

-

After-sales Service Provided:

-

Engineers

-

Name:

-

Accessary Roll Forming Machine

-

Usage:

-

Steel Construction

-

Raw material:

-

PPGI

-

Roller material:

-

45#steel Chrome Plated

-

Thickness:

-

0.3-0.8mm Thickness

-

Function:

-

Roof Usage

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

|

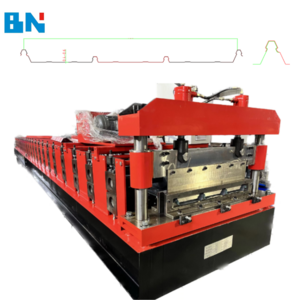

Superior Quality Colored Glazed Metal Roof Tile Roll Forming Machine

|

|

|

||

|

General details

|

Suitable Material

|

PPGI/PPGL/GI/GL

|

||

|

|

coil width

|

1000/1200/1250MM(according to your need)

|

||

|

|

Materials thickness

|

0.3mm-0.8mm

|

||

|

|

Dimension

|

About 7*1.4*1.5m(L*W*H) , as per the drawing

|

||

|

|

Length of the Sheet

|

can set the length according to your infact need.

It is controlled by PLC which can ensure the accuracy of ±1mm. |

||

|

|

Cutting

|

Automatically stop and cutting when it comes to the set length.

|

||

|

Components Details

|

Roller Material

|

High grade 45# steel. Hard chrome plating, 0.05mm.

|

||

|

|

Main Frame

|

350# steel. More stable and no shaking.

|

||

|

|

Middle Plate

|

16mm. We use thicker plates to ensure stability

of our products. |

||

|

|

Forming Steps

|

9-20 steps, according to the drawing.

|

||

|

|

Shaft Material

|

Φ70 mm, high grade 45# steel.

Treating process: tempering- finish turning, high rigidity, hard to deform. |

||

|

|

Cutting

Blade Material |

Cr12, hardness HRC60-62.

Treating process: heat treatment- plane abrasion- wire electrode cutting. |

||

|

|

Suitable Power

|

380V, 50 Hz, 3 phase(according to your need)

|

||

|

|

Screen

|

7 inch touch screen, easy to operate.Brand Delta or based on your need

|

||

|

|

PLC

|

Delta Brand (Or Panasonic /Siemens )

Well-adapted to various conditions, such as moisture, electromagnetic disturbance. |

||

|

|

Frequency Converter

|

Sanjing

It has the advantage of slowing down before cutting,

to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

||

|

|

Length

Measurement Device |

Omron, made in Japan.

It features with high accuracy and stability. |

||

FAQ

1. Q: Are you manufacturer?

A: Yes, we are manufacturer for more than ten years.

2. Q: What kind of payment term you can do?

A: We are flexible about payment terms, please contact us for details.

3. Q: What info you need before you make the proposal for a roll forming machine?

A: The profile drawings, material informations, your special requirements.

4. Q: What I should do if I just start to know roll forming machinery?

A: Contact us immediately, we provide free consultant pre-sales service.

5. Q: How to visit our company?

A: 1. Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

2. Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

3. Fly to Guangzhou aiport: By air From Guangzhou to Beijing airtpot; By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

6. Q: What is the Warranty?

A: Within 24 months, all technical staff are ready to serve you at any time.

7. Q:What can you do if the machine broken?

A: Our machine's warranty period is 24 months, if the broken parts can't repair, we will send new parts replace the broken parts free, but you need pay the express cost if after warranty period. we can negotiate to solve the problem, and we supply the technical support for whole life of equipment.

8. Q: If need technician to workshop to debug and teach, how to do?

A: We sent technician to your country to fix the machine. Buyer should bear cost including: visa, round trip

ticket and suitable accommodation, also buyer should pay the salary 100 USD/day.

A: We are flexible about payment terms, please contact us for details.

3. Q: What info you need before you make the proposal for a roll forming machine?

A: The profile drawings, material informations, your special requirements.

4. Q: What I should do if I just start to know roll forming machinery?

A: Contact us immediately, we provide free consultant pre-sales service.

5. Q: How to visit our company?

A: 1. Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

2. Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

3. Fly to Guangzhou aiport: By air From Guangzhou to Beijing airtpot; By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

6. Q: What is the Warranty?

A: Within 24 months, all technical staff are ready to serve you at any time.

7. Q:What can you do if the machine broken?

A: Our machine's warranty period is 24 months, if the broken parts can't repair, we will send new parts replace the broken parts free, but you need pay the express cost if after warranty period. we can negotiate to solve the problem, and we supply the technical support for whole life of equipment.

8. Q: If need technician to workshop to debug and teach, how to do?

A: We sent technician to your country to fix the machine. Buyer should bear cost including: visa, round trip

ticket and suitable accommodation, also buyer should pay the salary 100 USD/day.

Hot Searches