- Product Details

- {{item.text}}

Quick Details

-

Material:

-

carbon STEEL, Carbon steel or stainless steel

-

Application:

-

Wastewater Treatment Plant

-

Type:

-

Sewage Treatment Plant

-

Usage:

-

Kill Bacteria

-

Function:

-

Purify Sewage

-

Certification:

-

CE Certificate

-

Use:

-

Waste Water Cleaning

-

Feature:

-

Short construction period and simple installation

-

Advantage:

-

Fast Delivery

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YI XIN

-

Weight (KG):

-

500 kg

-

Material:

-

carbon STEEL, Carbon steel or stainless steel

-

Application:

-

Wastewater Treatment Plant

-

Type:

-

Sewage Treatment Plant

-

Usage:

-

Kill Bacteria

-

Function:

-

Purify Sewage

-

Certification:

-

CE Certificate

-

Use:

-

Waste Water Cleaning

-

Feature:

-

Short construction period and simple installation

-

Advantage:

-

Fast Delivery

Specification

|

item

|

value

|

|

Condition

|

New

|

|

Applicable Industries

|

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, Other

|

|

Showroom Location

|

None

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

New Product 2020

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

membrane

|

|

Place of Origin

|

China

|

|

|

Henan

|

|

Brand Name

|

YI XIN

|

|

Warranty

|

1 Year

|

|

Productivity

|

2000L/Hour

|

|

Weight (KG)

|

500kg

|

|

Material

|

carbon STEEL, Carbon steel or stainless steel

|

|

Application

|

Wastewater Treatment Plant

|

|

Type

|

Sewage Treatment Plant

|

|

Usage

|

Kill Bacteria

|

|

Function

|

Purify Sewage

|

|

Certification

|

CE Certificate

|

|

Use

|

Waste Water Cleaning

|

|

Feature

|

Short construction period and simple installation

|

|

Advantage

|

Fast Delivery

|

|

|

|

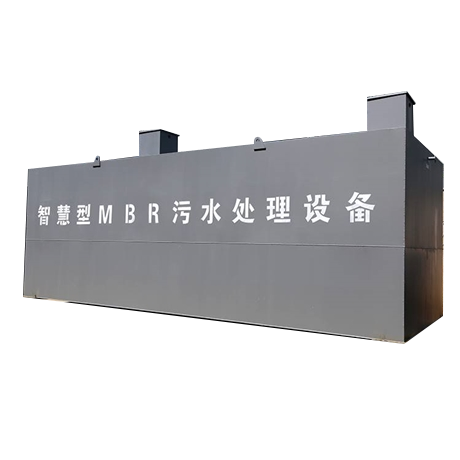

MBR integrated sewage treatment equipment, it is the membrane separation technology of ultrafiltration components and sewage biological treatment of the biological reactor combined to form our new sewage treatment and reuse equipment, its core components by our company independent research and development and production.

We integrate the high-end water treatment engineering technology accumulated in various water treatment actual construction over the years into a box to bring you tailor-made integrated solutions.

Integrated intelligent (MBR) purification equipment is mainly divided into two forms: above ground and buried.

Integrated intelligent (MBR) purification equipment system composition:

Anoxic tank: anoxic tank, as a pre-treatment unit, provides a site for microbial hydrolysis, acidification, denitrification, etc.

MBR membrane tank: membrane tank is the core part of MBR system, which realizes the deep purification of wastewater in bioreactor through efficient separation of plate membrane.

Clean water tank: clean water tank stores MBR filtered water, which can be reused with dosing or disinfection device.

Equipment room: a place to assemble mechanical and electrical equipment, the main equipment is blower, self-priming pump, PLC control system and membrane cleaning equipment.

Integrated intelligent (MBR) purification equipment

The manufacturing process is completed in the factory with controllable production cycle and reliable quality.

Simple site installation, short construction period, no structural concrete structures.

It is a decentralized on-site treatment equipment, which does not need to collect long sewage pipes for centralized treatment and

has low capital construction cost.

High degree of automatic control, no resident operation and maintenance personnel, online detection and remote control can berealized.

Integrated intelligent (MBR) purification equipment scope of application:

Hotel, supermarket, hotel, villa, community sewage treatment and reuse.

New rural areas, service areas, environmental protection public toilets, tourist attractions and other environmentally sensitive areas sewage treatment and reuse.

Universities, scientific research institutions, environmental protection enterprises scientific experiments.

The manufacturing process is completed in the factory with controllable production cycle and reliable quality.

Simple site installation, short construction period, no structural concrete structures.

It is a decentralized on-site treatment equipment, which does not need to collect long sewage pipes for centralized treatment and

has low capital construction cost.

High degree of automatic control, no resident operation and maintenance personnel, online detection and remote control can berealized.

Integrated intelligent (MBR) purification equipment scope of application:

Hotel, supermarket, hotel, villa, community sewage treatment and reuse.

New rural areas, service areas, environmental protection public toilets, tourist attractions and other environmentally sensitive areas sewage treatment and reuse.

Universities, scientific research institutions, environmental protection enterprises scientific experiments.

You are welcome to consult at any time, we will serve you 24 hours a day

1. who are we?

We are based in Henan, China, start from 2012,sell to Domestic Market(40.00%),Southeast Asia(20.00%),South

America(10.00%),Africa(5.00%),Eastern Asia(3.00%),Northern Europe(2.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Dewatering Belt Filter Press,MBR Membrane Bio Reactor,Submersible Aerator,Submersible Mixer,Plug Flow Aerator

4. Why should you buy from us not from other suppliers?

It can not only customize the various non-standard environmental protection equipment and engineering design according to user needs, but also provide fast engineering installation and equipment operation commissioning.

5. What services can we provide?

Accepted Delivery Terms: null;

Accepted Payment Currency:null;

Accepted Payment Type: null;

Language Spoken:null

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

We are based in Henan, China, start from 2012,sell to Domestic Market(40.00%),Southeast Asia(20.00%),South

America(10.00%),Africa(5.00%),Eastern Asia(3.00%),Northern Europe(2.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Dewatering Belt Filter Press,MBR Membrane Bio Reactor,Submersible Aerator,Submersible Mixer,Plug Flow Aerator

4. Why should you buy from us not from other suppliers?

It can not only customize the various non-standard environmental protection equipment and engineering design according to user needs, but also provide fast engineering installation and equipment operation commissioning.

5. What services can we provide?

Accepted Delivery Terms: null;

Accepted Payment Currency:null;

Accepted Payment Type: null;

Language Spoken:null

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches