- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

400*200*200mm

-

Product Name:

-

stumble blocks moulds

-

Mould material:

-

PP(EP-200K)

-

Size:

-

400*200*200mm

-

weight:

-

1.55kg/pair

-

Mould Life:

-

1500 Times

-

Application:

-

interlocking blocks

-

Certification:

-

PVOC/SONCAP

-

Color:

-

Green and orange

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TAIXIN

-

Model Number:

-

400*200*200mm

-

Product Name:

-

stumble blocks moulds

-

Mould material:

-

PP(EP-200K)

-

Size:

-

400*200*200mm

-

weight:

-

1.55kg/pair

-

Mould Life:

-

1500 Times

-

Application:

-

interlocking blocks

-

Certification:

-

PVOC/SONCAP

-

Color:

-

Green and orange

TECHNNICAL PARAMETERS:

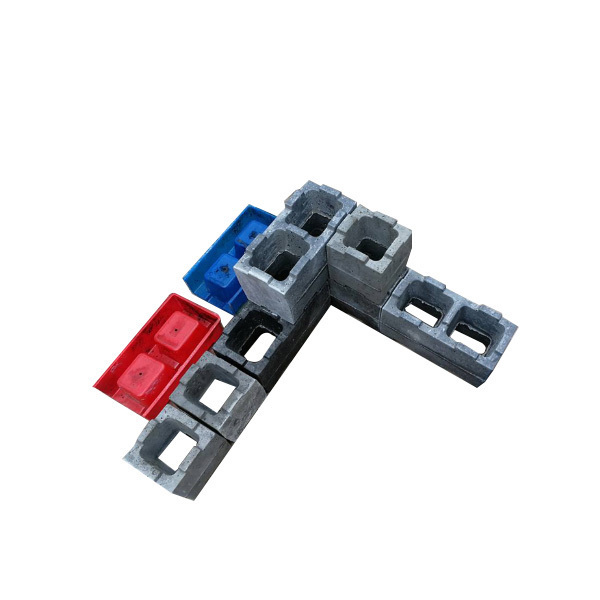

| Size | 400*200*200mm |

| Weight | 1.55kg/pair |

| Application | Making Cement Blocks |

| Feature | Easy To use |

| Color | Red ,Yellow |

| Warranty | 1000 Times |

INTRODUCTION:

|

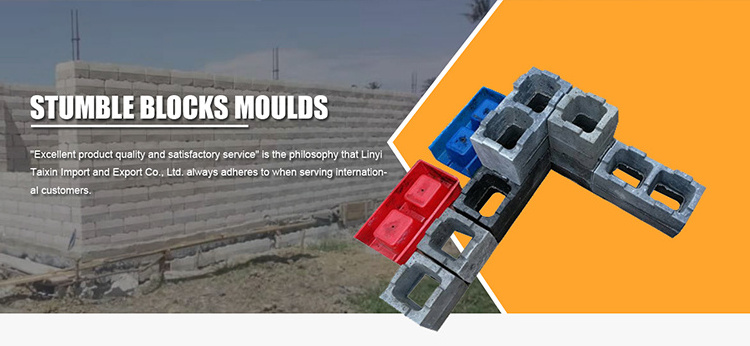

plastic stumble blocks moulds was invented to give anyone with limited skills and limited means the opportunity to build their own home in a cost effective way.

When removed from the mould, a very accurate hollow core block is created. The unique interlocking shape allows building with great ease and, in conjunction with the glue i.e. thin bed mortar and render (NHBRC approved building method), a very strong, fast and cheap construction method is created. |

Attention:

|

1.Block manufacturing should be done in some form of shade and not in direct sunlight. Direct sunlight and extreme variations of temperatures may cause the blocks to crack before they are properly cured.

3.Mould to stand up with open side at top. 4.Use the bolts, washers, and wing nuts provided to join the two halves (Yellow and Red) of mould together. Ensure that the washers provided are used on both sides to spread the load. Slide the aluminium strips/rails down each side of the joined mould. |

FAQ:

|

1.How strong is the block?

2.Can other fillings be used?

3.Can any sort of sand be used? Yes, any sort of concrete or plaster sand may be used but the finer the sand the weaker the finished block will be. Sand containing any organic material or salt should not be used. River sand is preferred. Sand with best properties comprise of particulars that has a variation of fine to coarse sand grains and must have no clay form.

4.How does stumble blocks save cost in building?

Much less material is used than in conventional building and the labour cost is a fraction of the normal rate because unskilled labour can be used to do the work of otherwise expensive artisans. For standard openings (windows/doors) Stumbelbloc may be used in place of lintels – saving time, money and procurement/delivery costs. Finally, the use of Stumbelbloc eliminates almost all building waste. Any surplus standard mortar can be used to make more blocks.

5.How does it save time?

The method of building is 10 times faster than normal. A standard structure can be built to roof height in one day. No time is wasted on setting up profiles and preparing mortar mixes. The labourer carrying the block actually lays it instead of handing it to the artisan. No time is spent cleaning up afterwards. If required, several labourers can work at the same time without interrupting each other's work. |