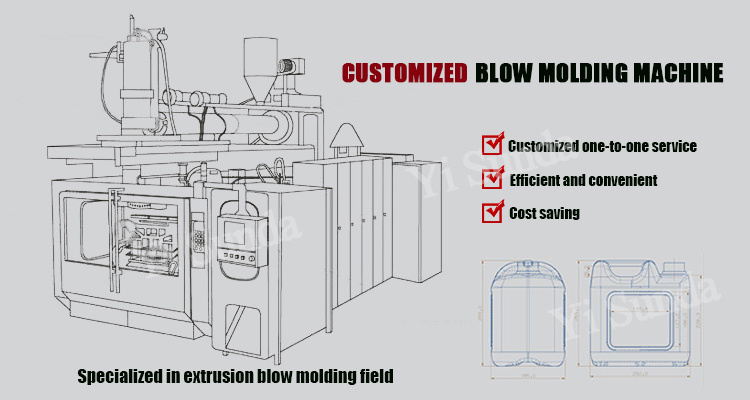

Our continous extrusion machine can adopt 1/2/3/4/6 head for wider product application range to fit bottles of different volume,

also match with related extrusion system it adopt view stripe head and multi-layer co-extrusion head to fit different functional

products.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YI SUNDA

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2600*1600*1900mm

-

Hollow part volume:

-

1.5L

-

Screw diameter (mm):

-

55 mm

-

Screw Heating Power(kW):

-

8 kW

-

Extruder Motor Power(kW):

-

7.5 kW

-

Mold Platen Size(Width)(mm):

-

230 mm

-

Mold Platen Size(Height)(mm):

-

400 mm

-

Air Pressure(MPa):

-

0.6 MPa

-

Air Comsumption(m³/min):

-

0.6 m³/min

-

Die Head Heating Power(kW):

-

8 kW

-

Accumulator Capacity(L):

-

1.5 L

-

Power (kW):

-

16.5

-

Weight (T):

-

1500

Quick Details

-

Clamping Force (kN):

-

None

-

Output (kg/h):

-

25 kg/h

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

YI SUNDA

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2600*1600*1900mm

-

Hollow part volume:

-

1.5L

-

Screw diameter (mm):

-

55 mm

-

Screw Heating Power(kW):

-

8 kW

-

Extruder Motor Power(kW):

-

7.5 kW

-

Mold Platen Size(Width)(mm):

-

230 mm

-

Mold Platen Size(Height)(mm):

-

400 mm

-

Air Pressure(MPa):

-

0.6 MPa

-

Air Comsumption(m³/min):

-

0.6 m³/min

-

Die Head Heating Power(kW):

-

8 kW

-

Accumulator Capacity(L):

-

1.5 L

-

Power (kW):

-

16.5

-

Weight (T):

-

1500

|

Model number

|

PSJ-1

|

|

Maximum product volume L

|

standard1.5L

|

|

Mould quantity (pay)

|

2

|

|

Yield (empty cycle)pc/h

|

600

|

|

Screw diameter mm

|

55

|

|

Length-diameter ratio of screw L/D

|

1:25

|

|

HDPE maximum extrusion capacity kg/h

|

25

|

|

Material pipe cutting mode

|

Hot knife

|

|

Maximum mold size (thickness * width * height)mm

|

220*230*400

|

|

Blowing pressure Mpa

|

0.4-0.6

|

|

Gas consumption m3/min

|

0.6

|

|

Extruder power KW

|

7.5

|

|

Extruder heating power KW

|

8

|

|

Total power KW

|

16.5

|

|

Overall dimension mm (length * width * height)

|

2600*1600*1900

|

|

Gross weight kg

|

1500

|

|

Control mode

|

PLC Computer control

|

|

Suitable material

|

PE/PP

|

Reasonable head runner design for color change quickly. Die & core individualizedaccording to your product width. Eachcylinder at

each side for head lifting smoothly.

each side for head lifting smoothly.

Its main function is to execute mould carriage up action, mould closing clampingparison action.mould carriaoe down actionsupply

clamping force to offset air blowingpressure.mould open for product de-molding

clamping force to offset air blowingpressure.mould open for product de-molding

Platen moving cylinders with mechanicalshuttlevalve to reduce impact force at end position.Highstationarity and

reliability.accurate operation,long longevity andquickresponse.

reliability.accurate operation,long longevity andquickresponse.

Famous brand, true color man-machine controlinterface. Simple and user-friendly page.easy to operate.

We have exporte to all over the worlds. for example Australia, Indonesia,Singapore, Thailand, Cambodia, Vietnam, Bangladesh,India,Pakistan, Mexico, Peru,Chile, Brazil, Egypt, South Africa, Nigeria, Sierra Leone, Sudan, Mali, Kazakhstan,Kyrgyzstan,Turkey, Iraq,etc.

FAQ:

1. Can I make milk bottle on this machine

Yes, you can. Milk bottle, detergent bottle,pattern pot are available on the machine.

2. What shall I provide to you for offer?

Please send us your bottle picture with width,length,weights etc and better to send samples.

3. What kinds of materials the blow machine make?

The blow molding machine can make HDPE,PP material bottles.

4. What is your delivery time?

30 days to 50days.

5. How can I trust your machine ?

- We have more than 10 years experience have own design team and experience

engineer.

- You can visit us to check.

- We give professional guidance service during enquiry period.

- We provide after sale install service to abroad clients.

1. Can I make milk bottle on this machine

Yes, you can. Milk bottle, detergent bottle,pattern pot are available on the machine.

2. What shall I provide to you for offer?

Please send us your bottle picture with width,length,weights etc and better to send samples.

3. What kinds of materials the blow machine make?

The blow molding machine can make HDPE,PP material bottles.

4. What is your delivery time?

30 days to 50days.

5. How can I trust your machine ?

- We have more than 10 years experience have own design team and experience

engineer.

- You can visit us to check.

- We give professional guidance service during enquiry period.

- We provide after sale install service to abroad clients.

Hot Searches