- Product Details

- {{item.text}}

Quick Details

-

Function:

-

waste oil refining

-

Capacity:

-

30T

-

End product:

-

base oil, diesel, gasoline

-

Type:

-

Continuous Oil Distillation Machine

-

Fuel:

-

gas, fuel oil, coal, wood,electricity

-

Power Supply:

-

16kw

-

Noise:

-

<85db

-

Structure:

-

horizontal vacuum

Quick Details

-

Place of Origin:

-

Henan, China

-

Name:

-

New nenergy crude oil continuous engine oil recycling plant

-

Raw material:

-

waste engine oil, tire oil, plastic oil, crude oil, rubber oil...

-

Function:

-

waste oil refining

-

Capacity:

-

30T

-

End product:

-

base oil, diesel, gasoline

-

Type:

-

Continuous Oil Distillation Machine

-

Fuel:

-

gas, fuel oil, coal, wood,electricity

-

Power Supply:

-

16kw

-

Noise:

-

<85db

-

Structure:

-

horizontal vacuum

New nenergy crude oil continuous engine oil recycling plant;

Henan Qingzhan Industrial CO.,Ltd is a collection of research and development, production, sales and after-sales services, which has rich experience in the field of waste management.

Our company covers an area of 37,000 square meters. Our company has a huge professional technical team, including 18 senior engineers, 16 senior technicians, 28 mid-class technicians, and 82 technicians.

Our main products are divided into two catalogries: pyrolysis plant and distillation machine , including tires

pyrolysis plant, tyre pyrolysis plant, waste rubber pyrolysis equipment, waste plastic recycling machine

and other waste management machines, and waste oil distillation equipment, waste engine/motor oil recycling machine, tire oil distillation plant, plastic oil refinery machine and crude oil distillation equipment.

Our products have been exported to China, South Korea, Thailand, the Philippines, India, Malaysia, Malaysia, Myanmar, Afghanistan and the United States and other countries and regions , which obtain a better reputationand happy feedback.

We will continue to innovate and improve to give you a nice turnkey projects.

| Mode | ZL-5 | ZL-6 | ZL-7 | ZL-8 | ZL-9 |

| Capacity | 5 | 10 | 15 | 20 | 30 |

| Size | 1.6*3m | 2*4.5m | 2.2*5.5m | 2.4*6.5m | 2.6*8m |

| Working from | continuous | continuous | continuous | continuous | continuous |

| Structure | Horizontal | Horizontal | Horizontal | Horizontal | Horizontal |

| Power | 16kw | 16kw | 16kw | 16kw | 16kw |

| Raw material | waste engine oil/crude oil/pyrolysis oil/black oil | waste engine oil/crude oil/pyrolysis oil/black oil | waste engine oil/crude oil/pyrolysis oil/black oil | waste engine oil/crude oil/pyrolysis oil/black oil | waste engine oil/crude oil/pyrolysis oil/black oil |

1 . Raw material:

a. Waste oil .example: waste diesel, waste oil residue etc.

b. rubber oil

c. plastic oil

d. waste original oil

e. waste engine/motor oil

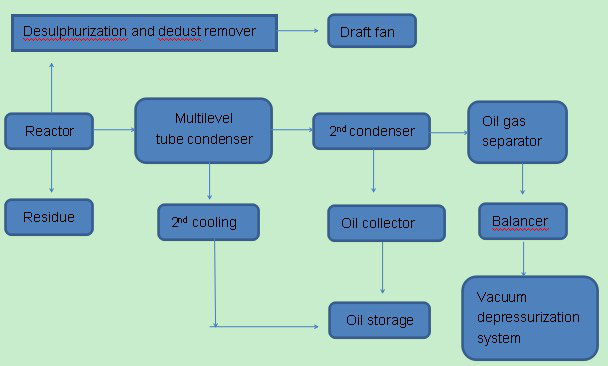

2. Components of Equipment

A. Vertical reactor/Horizontal reactor

B. Reducer system

C. Condensation system

D. Collector

E. Oil collecting tank

F. Residue tank

G. Oil-gas separator

H. Water cooling system

I. Water seal

J. Pressure & Temperature monitoring gauge

K. Deodorization system

L. Efficient anti clog cooling system

M. Gas heating system (waste gas process system)

N. Smoke desulphurization and dust removal system

3. Production flow:

4. Products features:

a. Reduce pressure distillation technology

This new technology is better than original ordinary pressure distillation technology, which shows on purity, transparence, and lightness. This technology will do deodorization and destinke process to the raw material oil automatically by "dry type" reduce pressure distillation method, which can fall of the temperature of distill process and the oil output will higher 5%-10%.

b. Continuous produce 24-hours

24-hours raw material put into automatically according to oil output flow and reactor temperature.

c. High efficient gas heating system

During this process, it will produce a large amount of gas CH4-C2H6, which cannot be fluidity with normal temperature and pressure. Those gas will be fully burned in the special gun nozzle and produce a plenty energy.

d. Intelligence smoke dust removal system

The smoke dust removal system with intelligence desulphurization, have a special with bi-directional water impact cyclone dust remove room, which can ensure the smoke discharge amount meet governmental relative standards.

We can send our engineer to your side for guiding the installation and training your workers operation.