- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KAITE

-

Model Number:

-

KT-CFBC

-

Application:

-

Raw material of ceramic fiber products

-

Dimensions:

-

As request

-

Working Temperature:

-

1000-1350°C

-

Fiber Diameter:

-

2-5um

-

Thermal Conductivity:

-

0.09-0.20w/m.k

-

Shrinkage (1800℉, 3h):

-

-3%

-

Color:

-

Pure White

-

Blown fiber diameter:

-

2-3um

-

Swinging fiber diameter:

-

3-4.5um

Quick Details

-

Ultimate Strength (≥ MPa):

-

0.04

-

Density (kg/m³ ):

-

128

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

KAITE

-

Model Number:

-

KT-CFBC

-

Application:

-

Raw material of ceramic fiber products

-

Dimensions:

-

As request

-

Working Temperature:

-

1000-1350°C

-

Fiber Diameter:

-

2-5um

-

Thermal Conductivity:

-

0.09-0.20w/m.k

-

Shrinkage (1800℉, 3h):

-

-3%

-

Color:

-

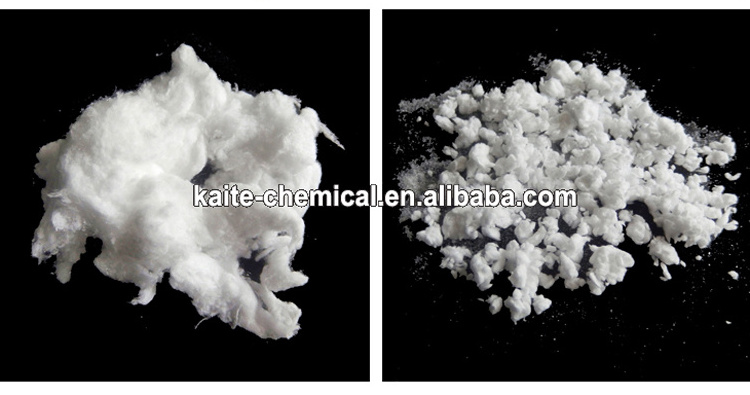

Pure White

-

Blown fiber diameter:

-

2-3um

-

Swinging fiber diameter:

-

3-4.5um

Ceramic fiber bulk is made from high purity clay clinker, alumina powder, silica powder and other raw materials by melting in high temperature industrial electrical furnace, through blow or spun production techniques drawn into fiber. Ceramic fiber bulk can be further processed into fiber blanket, board, paper, cloth, rope and other products. Ceramic fiber is a kind of high efficient thermal insulation material, which has the advantages of light weight, high strength, anti-oxidation, low thermal conductivity, good flexibility, corrosion resistance, low heat capacity and sound insulation etc..

1. Excellent thermal and chemical stability.

2. Low heat capacity and low thermal conductivity.

3. Excellent thermal shock resistance.

4. No bonding agent and corrosive substance.

5. Excellent sound absorption and fire performance.

6. Convenient to cut or install.

1. Raw material for fiber blanket, board products.

2. Raw materials for ceramic fiber products.

3. Raw material for fiber textile products.

4. Joint sealing and filling insulation.

5. Fiber composite.

6. Lining for industrial furnaces.

7. Fire protection and sound insulation.

|

Type |

Common |

Standard |

High purity |

High aluminum |

Zirconium |

|

|

Classification temp. (°C) |

1100 (2012 ℉ ) |

1260 (2300 ℉ ) |

1260 (2300 ℉ ) |

1360 (2480 ℉ ) |

1430 (2606 ℉ ) |

|

|

Work temp. (°C) |

<1000 (1832 ℉ ) |

1050 (1922 ℉ ) |

1100 (2012 ℉ ) |

1200 (2192 ℉ ) |

1350 (2462 ℉ ) |

|

|

Color |

Pure white |

Pure white |

Pure white |

Pure white |

Pure white |

|

|

Fiber diameter (um) |

Blown |

2-3 |

2-3 |

2-3 |

2-3 |

2-3 |

|

Needled |

3-4.5 |

3-4.5 |

3-4.5 |

3-4.0 |

3-4.0 |

|

|

AL 2 O 3 |

44 % |

46 % |

47-49 % |

52-55 % |

39-40 % |

|

|

AL 2 O 3 +SiO 2 |

96 % |

96 % |

99 % |

99 % |

- |

|

|

AL 2 O 3 +SiO 2 +ZrO 2 |

- |

- |

- |

- |

99 % |

|

|

ZrO 2 |

- |

- |

- |

- |

15-17 % |

|

|

Fe 2 O 3 |

<1.2 % |

<1.0 % |

0.2 % |

0.2 % |

0.2 % |

|

|

Na 2 O+K 2 O |

≤0.5 % |

≤0.5 % |

0.2 % |

0.2 % |

0.2 % |

|