- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TIANHUA

-

Product name:

-

Ceramic Packing

-

model:

-

3/4"

-

Size:

-

33x18x2.8

-

Specific surface area:

-

330/100

-

Porosity:

-

69

-

Bulk density:

-

720

-

Stacked number:

-

111548

-

Advantage:

-

Good quality and low price

-

application:

-

Chemical industries

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Gansu, China

-

Model Number:

-

0.5"/1"/1.5" or custom

-

Brand Name:

-

TIANHUA

-

Product name:

-

Ceramic Packing

-

model:

-

3/4"

-

Size:

-

33x18x2.8

-

Specific surface area:

-

330/100

-

Porosity:

-

69

-

Bulk density:

-

720

-

Stacked number:

-

111548

-

Advantage:

-

Good quality and low price

-

application:

-

Chemical industries

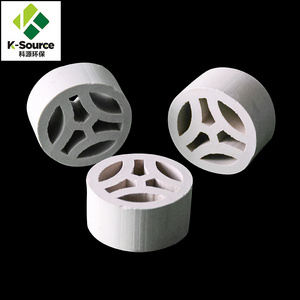

Ceramic moment saddle ring and different saddle ring are a kind of high-efficiency packing that is widely used at present. They are not only used in drying towers, absorption towers, cooling towers, regeneration towers in chemical, metallurgy, gas, oxygen production and other industries, but also as heat storage. Fillers are used in energy-saving and environmentally friendly equipment for processing low-concentration volatile organic waste gas in petrochemical, paint production, painting, printing, electronic components, integrated circuits and wires, pesticides and dyes, medicine, picture tubes, films, and light industry.

|

Ceramic intalox berl saddles |

|||||

|

Model |

Size |

Specific surface area |

Porosity rate |

Bulk density |

Stacked number |

|

0.5” |

21x21x1.8 |

430/131 |

68 |

741 |

355820 |

|

5/8” |

24x24x2.0 |

378/115 |

68.5 |

723 |

232980 |

|

3/4” |

33x18x2.8 |

330/100 |

69 |

720 |

111548 |

|

1” |

38x22x3.4 |

258/78 |

69.5 |

700 |

62128 |

|

1.5” |

60x30x4.0 |

197/60 |

73 |

635 |

23368 |

|

2” |

80x40x5.0 |

120/36 |

74 |

600 |

8860 |

|

3” |

114x57x8.0 |

92/28 |

75 |

582 |

3000 |

|

4” |

136.5x72.5x11 |

78/24 |

76 |

550 |

1606 |

Alkli-Resistant Ceramic Saddles