The max. loading weight: Running: 60Kg/m, stop: 150Kg/m

Running direction: two directions

Driving motor: SEW / NORD

Extending motor: SEW / NORD with brake

Frame material: 16 Mn

Surface treatment: Epoxy resin spraying

Rotary Bearing: SKF Joint bearing

Lighting: LED lights

Lifting angle: 7°

Belt: PVK

Conveying speed: 20~35m/min

SIEMENS PLC, Schneider electric parts

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BC

-

Voltage:

-

380V/415V

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

600 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Telescopic belt conveyor

-

Running speed:

-

20~35m/min

-

Max. loading weight:

-

Running: 60Kg/m, stop: 150Kg/m

-

Running direction:

-

two directions

-

Motor:

-

Top quality brand

-

Rotary bearing:

-

Top quality brand

-

Belt:

-

PVK

-

Lift angle:

-

7 degrees

-

Lights:

-

Yes

Quick Details

-

Power:

-

3kw

-

Warranty:

-

1 Year

-

Width or Diameter:

-

800mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BC

-

Voltage:

-

380V/415V

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

600 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Telescopic belt conveyor

-

Running speed:

-

20~35m/min

-

Max. loading weight:

-

Running: 60Kg/m, stop: 150Kg/m

-

Running direction:

-

two directions

-

Motor:

-

Top quality brand

-

Rotary bearing:

-

Top quality brand

-

Belt:

-

PVK

-

Lift angle:

-

7 degrees

-

Lights:

-

Yes

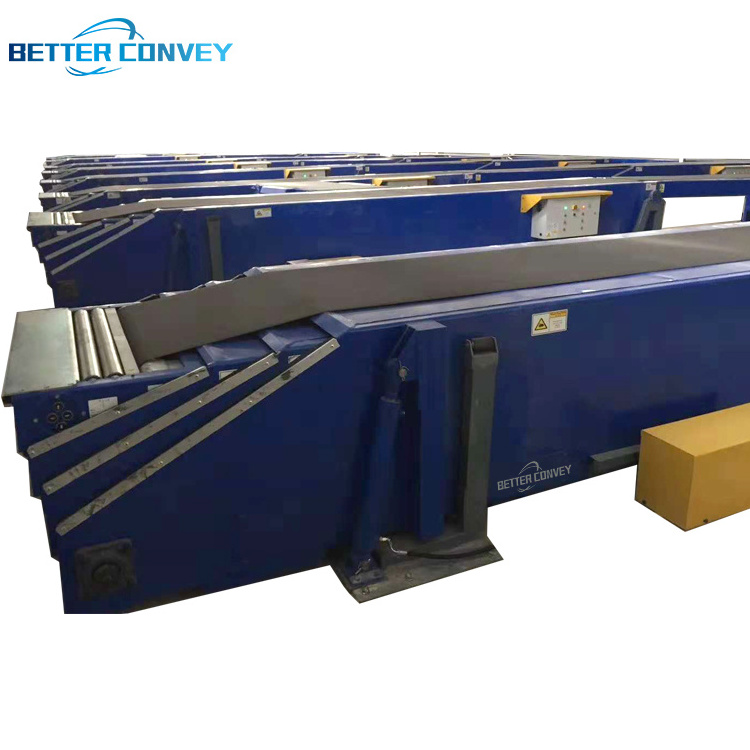

Telescopic belt conveyor

Features

1.The telescopic belt conveyor is mainly composed of fixed part, movable part, synchronous telescopic thrust mechanism, belt conveyor mechanism, protective rod mechanism and control system. The fixed part and movable part are made of manganese steel with a thickness of 6 mm / 5 mm.

2.The fore end shall be rigidly constructed to withstand the impact load during loading and unloading of luggage. The length should not be less than 300 mm (gravity roller conveyor inside the telescopic machine), should be zinc coated on the surface of the drum.

3.It has function of expanding while conveying the goods to improve the conveying efficiency and has the point to point working mode.

4.The front button has a protective baffle, which can effectively protect the button and prevent the button from being damaged when the belt conveyor is expanding and contracting.

5.The front end of the telescopic machine is equipped with anti-collision rod.

6.The front end should be equipped with LED lights to ensure the brightness of the truck during loading and unloading.