- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

customization

-

Product name:

-

HDPE part

-

Material:

-

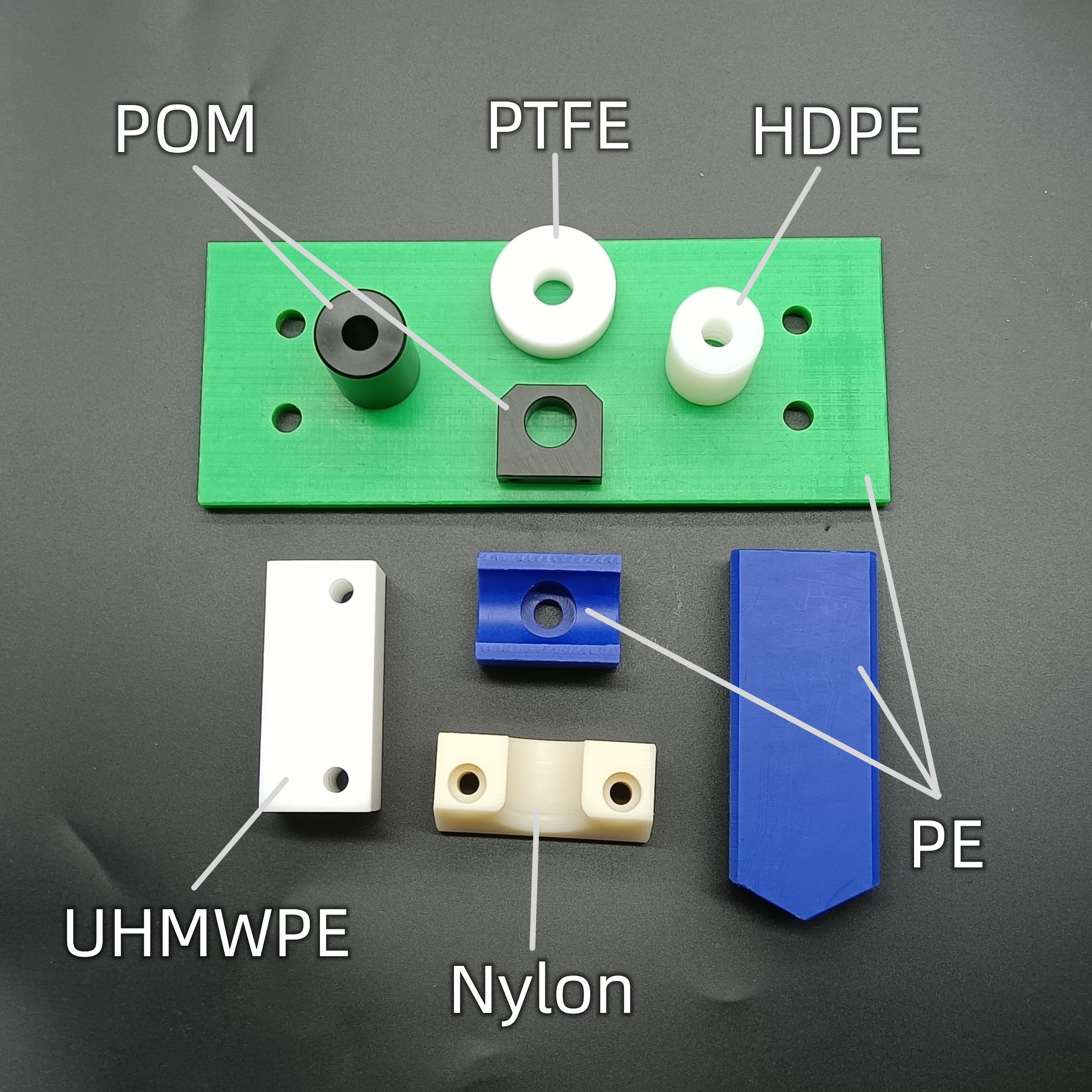

POM,PP,PE

-

Color:

-

custom color

-

Application:

-

Industrial

-

Service:

-

OEM\ODM

-

MOQ:

-

10pcs

-

Packing:

-

Standard Packing

-

Feature:

-

Durable

-

Certification:

-

ISO9001:2015

-

Tolerance:

-

0.02mm -0.05mm

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

MINGZE

-

Model Number:

-

customization

-

Product name:

-

HDPE part

-

Material:

-

POM,PP,PE

-

Color:

-

custom color

-

Application:

-

Industrial

-

Service:

-

OEM\ODM

-

MOQ:

-

10pcs

-

Packing:

-

Standard Packing

-

Feature:

-

Durable

-

Certification:

-

ISO9001:2015

-

Tolerance:

-

0.02mm -0.05mm

Product Description

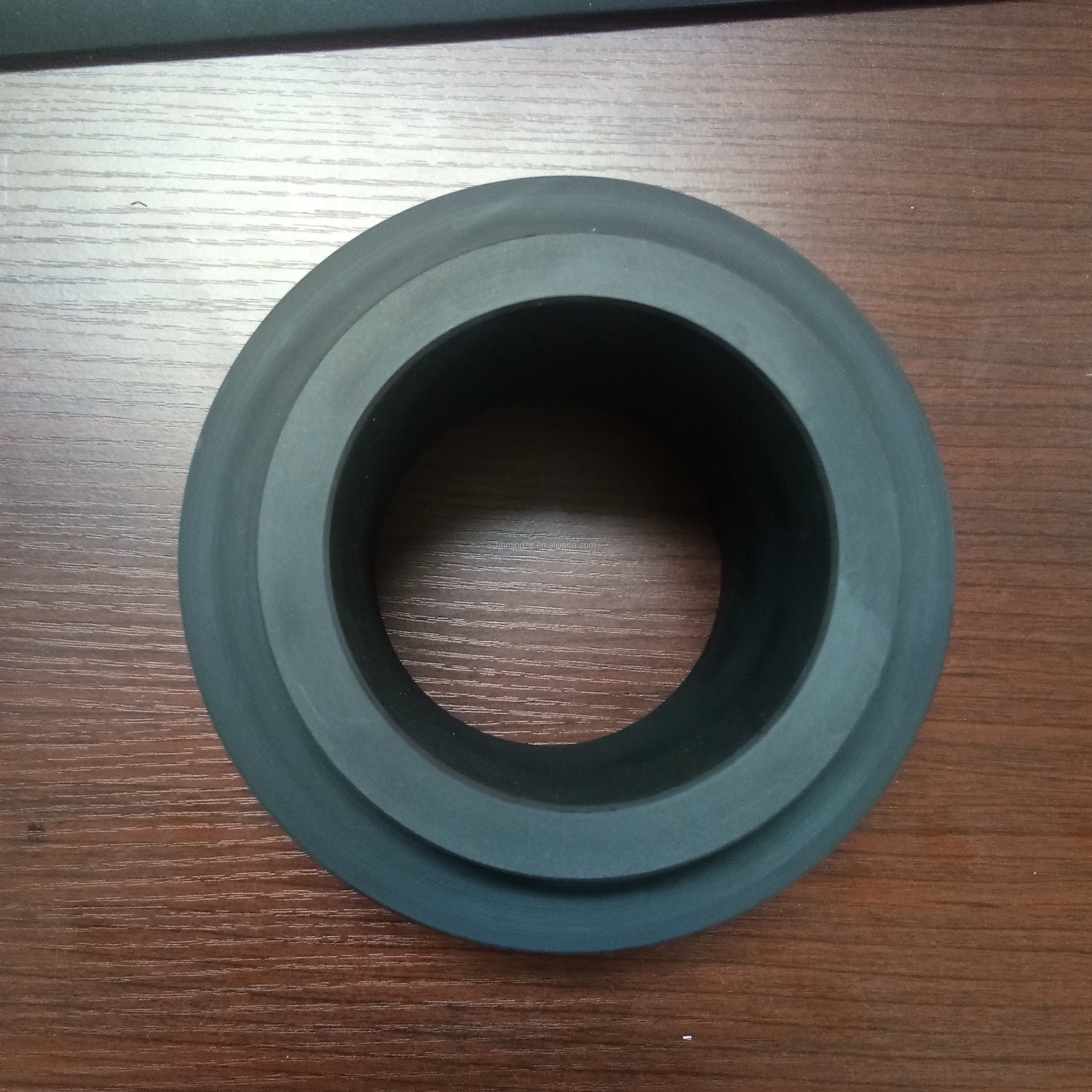

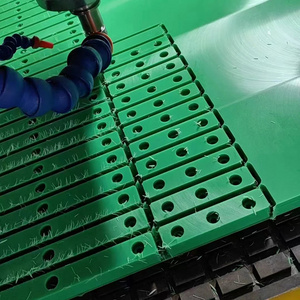

Custom UHMWPE HDPE PE PP nylon CNC machine wear resistant irregular plastic parts

Specification

|

We promise

|

All customer-centric, never for short-term profit, and sell long-term benefits

|

|

|

||

|

We produce

|

Mold, prototype, injection molding, product assembly, surface printing, spraying the surface integration

|

|

|

||

|

Pls provide

|

2D, 3D, samples, or the size of the multi-angle pictures

|

|

|

||

|

Mould Time

|

20-35 Days

|

|

|

||

|

Product time

|

7-15 Days

|

|

|

||

|

Moud precision

|

+/-0.01mm

|

|

|

||

|

Mould life

|

50-100 million shots

|

|

|

||

|

Producing Process

|

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode

machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

|

||

|

Mould cavity

|

One cavity, multi-cavity or same different products be made together

|

|

|

||

|

Mould material

|

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13

|

|

|

||

|

Runner system

|

Hot runner and cold runner

|

|

|

||

|

Base material

|

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13

|

|

|

||

|

Finish

|

Pitting the word, mirror finish, matte surface, striae

|

|

|

||

|

Standard

|

HASCO, DME or dependent upon

|

|

|

||

|

Main thechnology

|

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

|

|

|

||

|

Software

|

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances)

|

|

|

||

|

Product material

|

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV, TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS.

|

|

|

||

|

Quality system

|

ISO9001:2008

|

|

|

||

|

Establish time

|

20days

|

|

|

||

|

Equipment

|

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcasemould

|

|

|

||

Packing & Delivery

Internatinal standard packing with plastic film, shrink, pallet, wooden case, carton or others

Hot Searches