- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Azimuth Bolt and spherical nut

-

Advantage:

-

High Performance

-

Packing:

-

wooden case

-

Quality:

-

High Level

-

MOQ:

-

1 Piece

-

Application:

-

Construction

-

Usage:

-

Hole Drilling

Quick Details

-

Weight (KG):

-

100

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

coppern

-

Product name:

-

Azimuth Bolt and spherical nut

-

Advantage:

-

High Performance

-

Packing:

-

wooden case

-

Quality:

-

High Level

-

MOQ:

-

1 Piece

-

Application:

-

Construction

-

Usage:

-

Hole Drilling

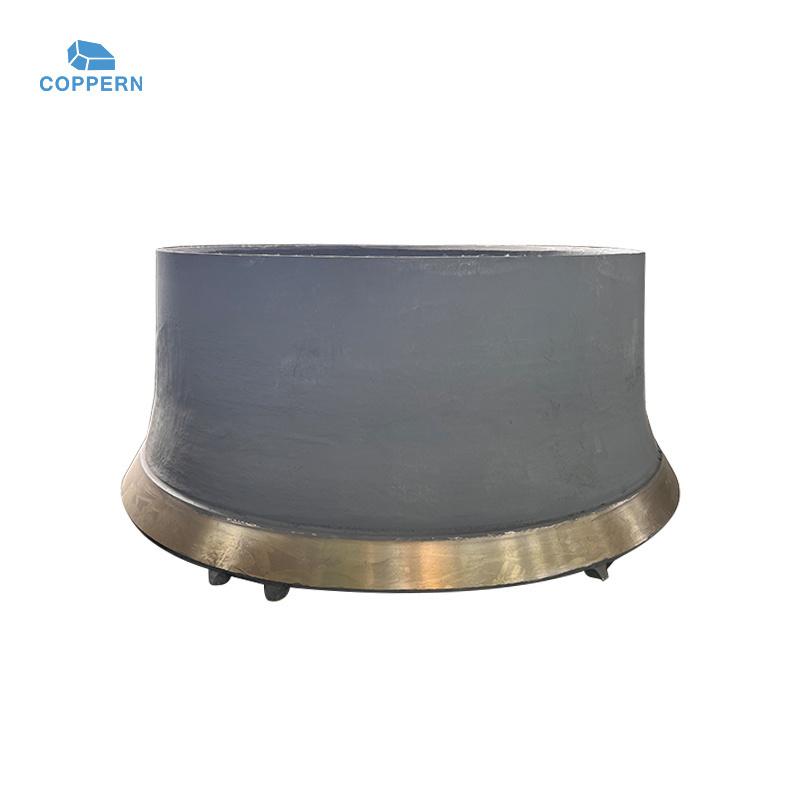

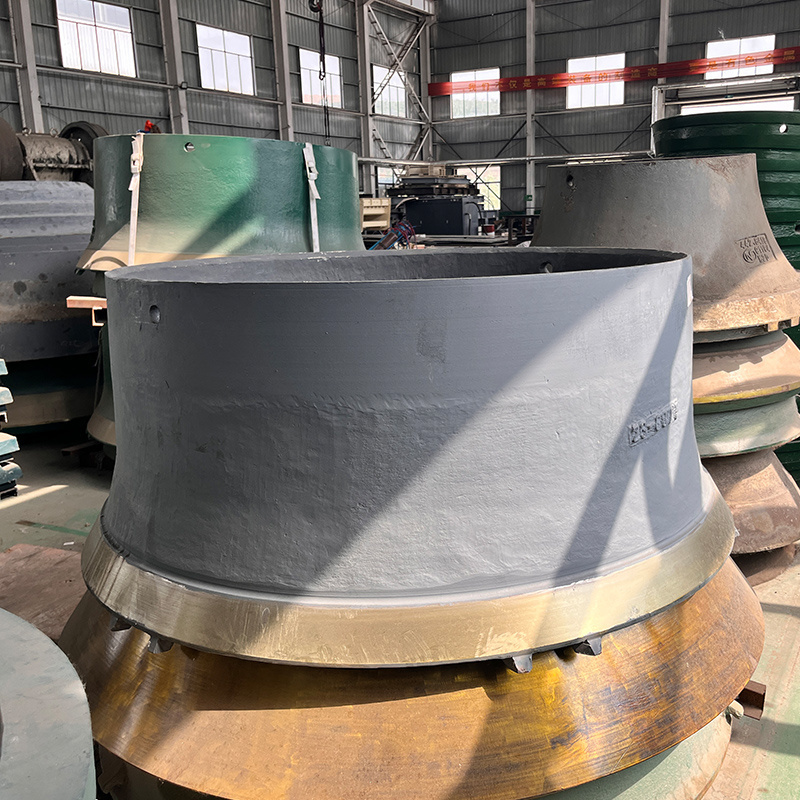

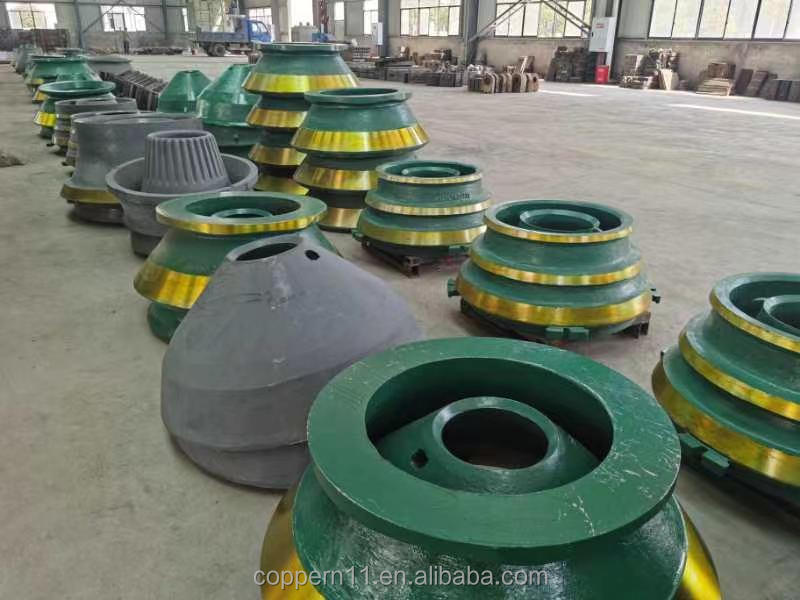

Specification

|

Items

|

Concave, Mantle, Concave Ring, Concave Segment , Bowl Liner,Cone Liner,Arm Guard, Distribution Plate

|

|

Casting Material

|

Manganese Steel (Mn14, M14Cr2, Mn18Cr2, Mn22Cr2)

|

|

Casting Method

|

Water Glass Sand Casting

|

|

Applicable Material

|

Gravel, Granite, Basalt, Ore, Limestone, Sandstone ,Quatz,Cobblestone

|

|

Applications

|

Mining , Quarry, Construction ,Cement and Materials ,Recycling

|

Product Description

The main wear parts of cone crusher and jaw crusher are sleeve, concave and jaw plate. Coppern is a professional supplier of high chromium alloy cast iron, high manganese steel, super high manganese steel and other wear-resistant chromium alloy cast iron. Most of our products use Mn13Cr2 and Mn18Cr2, which are suitable for many well-known domestic and foreign brands of crushers

|

Service Models

|

|

|

|

Cone Crusher

|

GP100/100S GP200/200S GP300/P300S GP500/500S GP220/GP550/GP11F

|

|

|

|

HP100/HP200/HP300/HP400/HP500/HP700/HP800/HP4/HP5/HP6

|

|

|

|

CH420/CH430/CH440/CH660/CH870/CH880/CS420/CS430/CS440/CS660

|

|

|

Jaw Crusher

|

C63/C80/C95/C96/C100/C105/C106/C110/C125/C140/C145/C160/C200

|

|

|

|

CJ408/CJ409/CJ411/CJ612/CJ613/CJ615/CJ815

|

|

Main Features

1) Simple structure in linear type,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution.

5) Apply a linker to connect with the air conveyor,which can directly inline with filling machine.

4) Running in a high automatization and intellectualization,no pollution.

5) Apply a linker to connect with the air conveyor,which can directly inline with filling machine.

|

High manganese casting material chemical composition

|

|

|

|

|

|

|||||

|

Material

|

C

|

Si

|

Mn

|

P

|

S

|

|||||

|

Mn13Cr2

|

1.05-1.35

|

0.30-0.90

|

12-14

|

≤0.06

|

≤0.04

|

|||||

|

Mn18Cr2

|

1.05-1.35

|

0.30-0.90

|

17-19

|

≤0.06

|

≤0.04

|

|||||

|

Mn21Cr2

|

1.05-1.35

|

0.30-0.90

|

20-23

|

≤0.06

|

≤0.04

|

|||||

Success stories

Hot Searches