- Product Details

- {{item.text}}

Quick Details

-

Power:

-

0-80KW

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

100 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

beer brewing equipment for micro brewery

-

Standard:

-

CE TUV.

-

Material:

-

SUS 304, SUS 316

-

Polish:

-

0.6um

-

Thickness:

-

Inner:4.0mm, Jacket: 2.0mm

-

Pressure:

-

Test: 0.3Mpa

-

Capacity in liters:

-

200L,3000L, 5000L, 1000L, 2000L, 3000L, 4000L,5000L.

-

Capacity in BBL:

-

3BBL, 5BBL, 7BBL, 10BBL, 20BBL, 30BBL, 40BBL.

-

Insulation:

-

100mm Polyurethane

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Cassman

-

Voltage:

-

Adjustable

-

Power:

-

0-80KW

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

100 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

beer brewing equipment for micro brewery

-

Standard:

-

CE TUV.

-

Material:

-

SUS 304, SUS 316

-

Polish:

-

0.6um

-

Thickness:

-

Inner:4.0mm, Jacket: 2.0mm

-

Pressure:

-

Test: 0.3Mpa

-

Capacity in liters:

-

200L,3000L, 5000L, 1000L, 2000L, 3000L, 4000L,5000L.

-

Capacity in BBL:

-

3BBL, 5BBL, 7BBL, 10BBL, 20BBL, 30BBL, 40BBL.

-

Insulation:

-

100mm Polyurethane

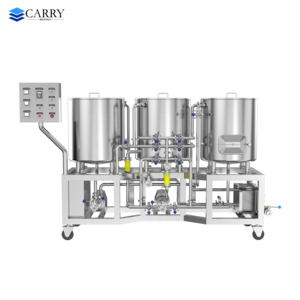

1000l Electric Heating Mash Tun Beer Brew Kettle 2/3/4 Vessels Brewhouses

1: 1000L brewhouse equipment with bottom footprint and operation platform

2: Heating methods can use electricity, gas, or steam

3: The device installation is very simple and can be completed in about a week

4: Cassman provides a complete set of equipment for brewing processes,

|

Brewing System |

Components |

Capacity |

Specification |

|

Grinding System |

Miller |

300KG/H |

Stainless steel, Double Roller, Noise<40db |

|

Brewhouse System |

Mash/Lauter tun

|

500L |

Mashing with mixing system False bottom support at the bottom of the tank

Full glass top manway

Interior:3 mm Exteior:2 mm Insulation: 80mm |

|

Brew Kettle/ Whirlpool Tank |

500L |

||

|

Fermentation System |

Fermentation Tank |

500L/1000L |

Side manway Test pressure 2 bar, working pressure 1.5 bar Interior:3 mm Exteior:2 mm Lifting ear Dry hopping PRV( Pressure release valve) Pressure gauge Spunding valve Sample valve Temperature gauge Carbonation stone Racking arm CIP spray device Drain outlet Solenoid valve 4 adjustable legs |

|

Cooling System |

Glycol Water tank |

1000l |

SUS 304 Insulation: 80mm With level gauge |

|

Chiller |

5HP |

Refrigerant: FreonR407C |

|

|

CIP System |

Sterilization tank |

50L |

working capacity: 50L; Inner tank thickness: 1.5mm; Light-banded welding line; Power: 2kw With valves and accessories |

|

Alkali Tank |

50L |

||

|

Pump |

3T/h |

||

|

Control System |

Control Cabinet |

Manual/PLC/ HMI |

Manual/Semi-automatic/Automatic |

|

Optional |

Auger System |

||

|

Grist Case |

|||

|

Grist Hydrator |

|||

|

Customized |

|||

Warranty:

Equipment warranty includes tank warranty, electric parts warranty, auxiliary parts warranty, etc. .

1, Cassman provides 3-5 years warranty for the main tank, 1 year warranty for electrical components and auxiliary parts, etc., and lifetime after-sales service.

2, In order to ensure the normal operation of the brewery, we can provide a separate set of spare parts according to the customer's request, customers can replace parts in case of abrasion damage.

Maintenance:

During operation, daily maintenance for the equipment is important. Cassman will provide maintenance guide., if need, we can send engineer to customer's site for repair and maintenance.

Beer equipment model selection:

1, Based on years of experience, Cassman can provide standard models of beer brewing equipment. We have mature experience in brewing technology and equipment design.

2, Cassman can provide custom-made service as per customer's requirement. including customize brewhouse system, fermentation tank, brite beer tank, coffee equipment, whiskey distillation equipment, stainless steel tank, etc.

Brewery design:

Cassman can help to design layout for newly built brewery, and we will supply P&ID drawings, electrical connection diagrams,flow chart, tank drawings, etc. , 3D drawings are also available if needs.

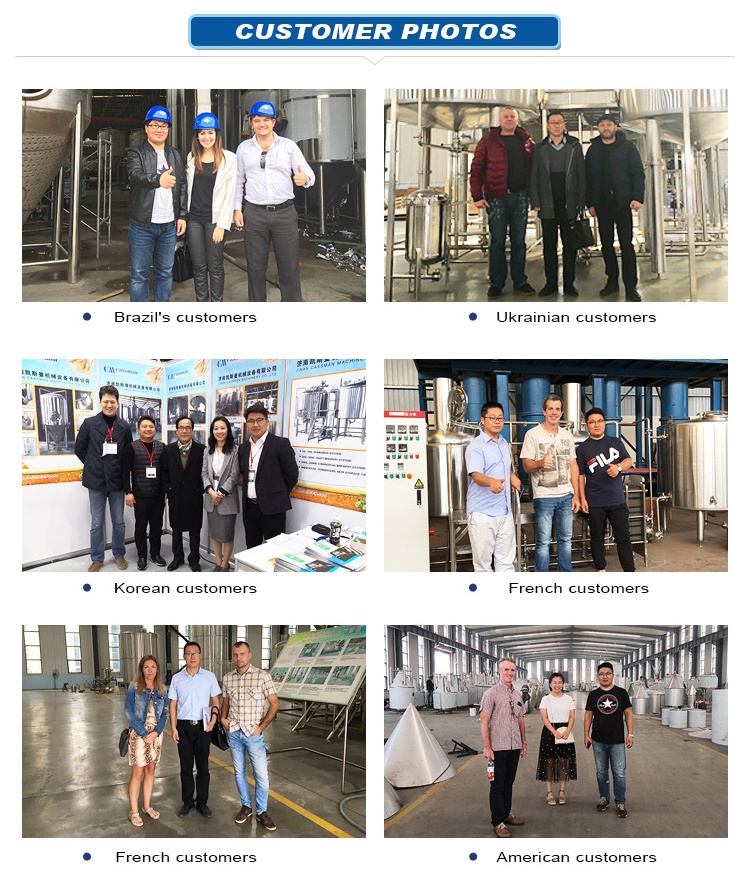

Installation:

Cassman has 6 to 8 experienced technical engineers, we can provide on-site installation and debugging instruction as per customer's needs.

1, To ensure good after-sales service, we will appoint the same technical personnel to debug and load the equipment before delivery,

2, For single tank, if on-site installation service is unnecassary, Cassman will provide equipment drawings and installation guides so that customers can install by themselves.

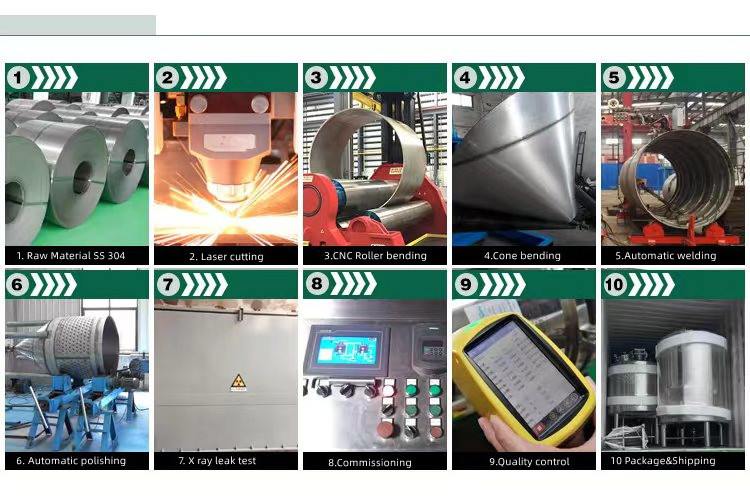

1:All material are SUS 304 or SUS 316.

2:Cassman company equipped with large-scale automatic tools such as laser cutting machines, automatic welding machines, automatic polishing machines, and inspection rooms, ensuring flawless processing details of the equipment.

3:All equipment is tested and debugged before shipment, ensuring that a complete set of perfect solutions arrive at the customer's hands.

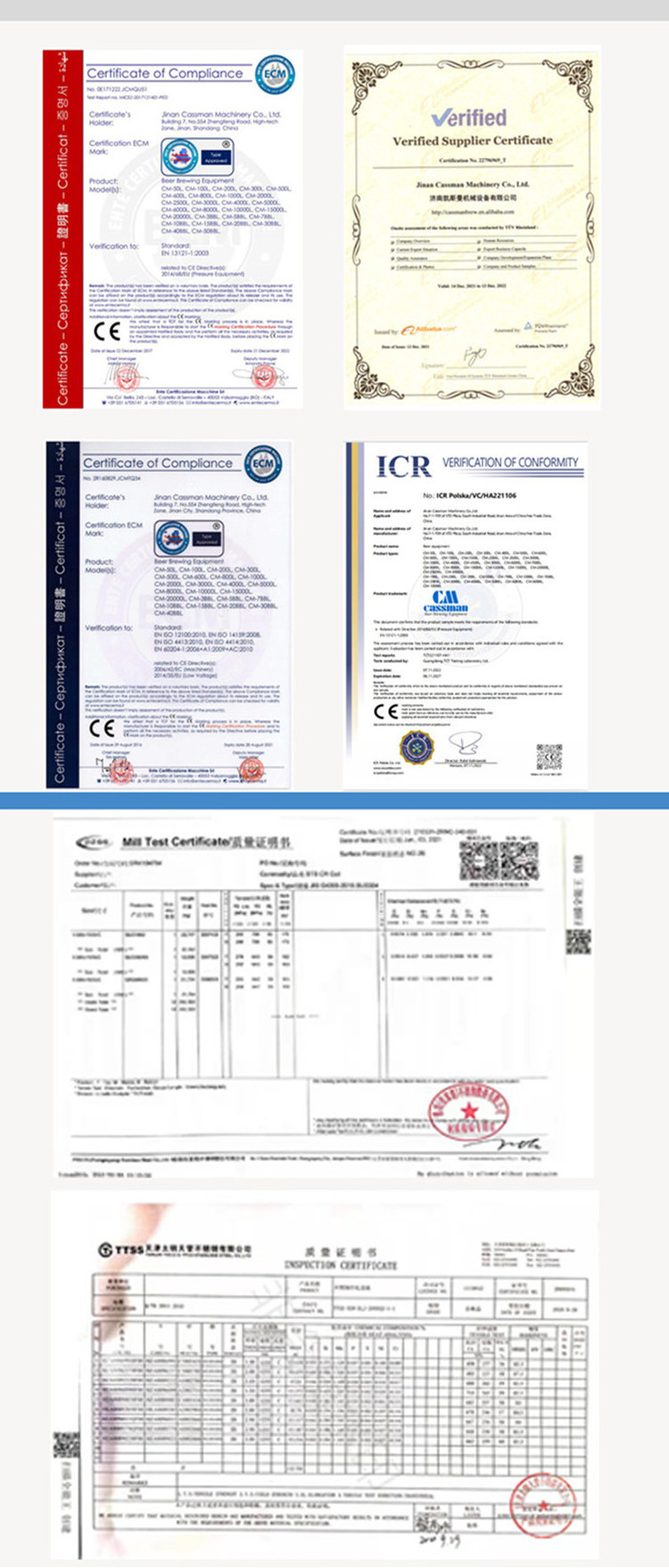

CE: Certification of Compliance

PED(TUV): Certification of Compliance, Certification of Conformity

SGS: Gold Plus Supplier Assessment Certificate

Material certification of the SUS 304, 316.