- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

OND

-

Product name:

-

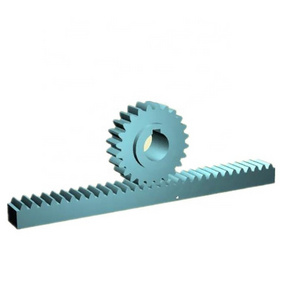

Straight Gear Rack

-

Tooth Profile:

-

Straight Teeth

-

Application:

-

Application

-

Length:

-

500mm,1000mm

-

pressure angle:

-

20°

-

Process:

-

Milling teeth

-

Color:

-

Natrul

-

Module:

-

as demands

-

Precision:

-

DIN6/DIN7/DIN8

Quick Details

-

Weight (KG):

-

1

-

Marketing Type:

-

New Product 2024

-

Core Components:

-

gear rack

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

OND

-

Product name:

-

Straight Gear Rack

-

Tooth Profile:

-

Straight Teeth

-

Application:

-

Application

-

Length:

-

500mm,1000mm

-

pressure angle:

-

20°

-

Process:

-

Milling teeth

-

Color:

-

Natrul

-

Module:

-

as demands

-

Precision:

-

DIN6/DIN7/DIN8

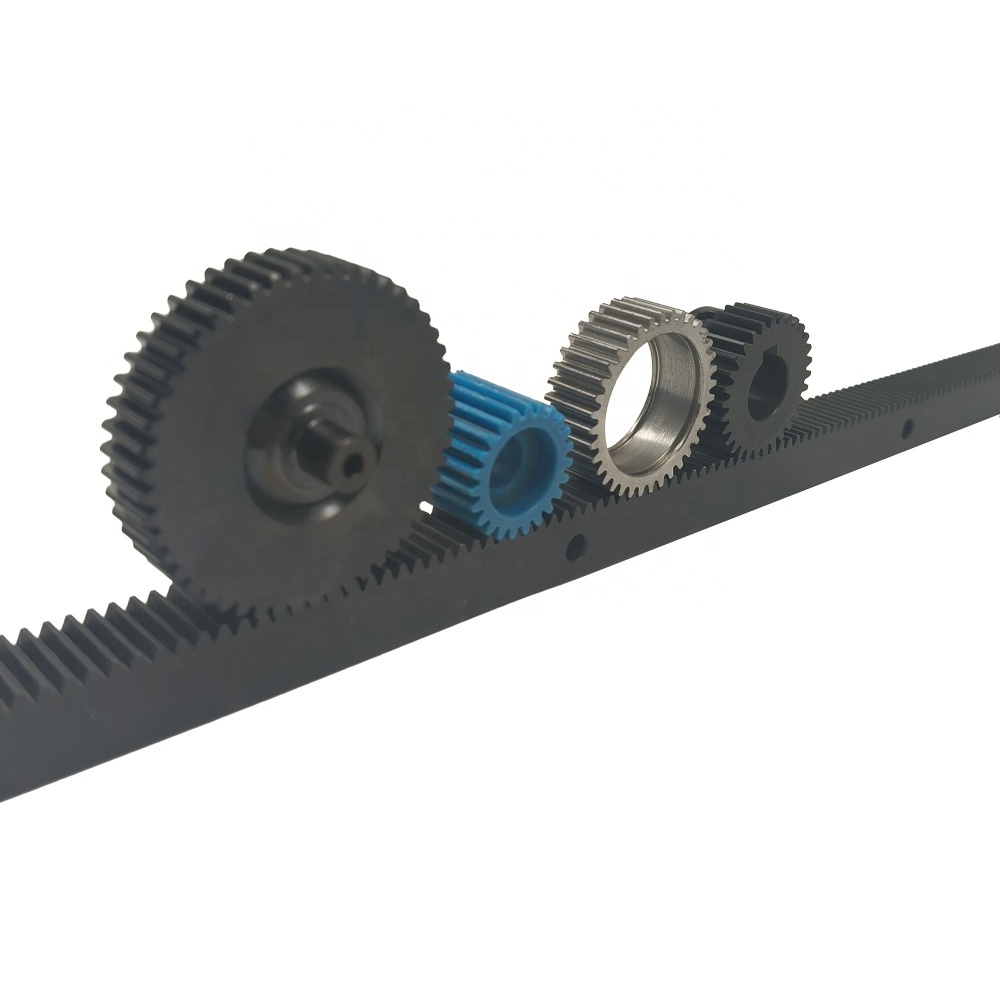

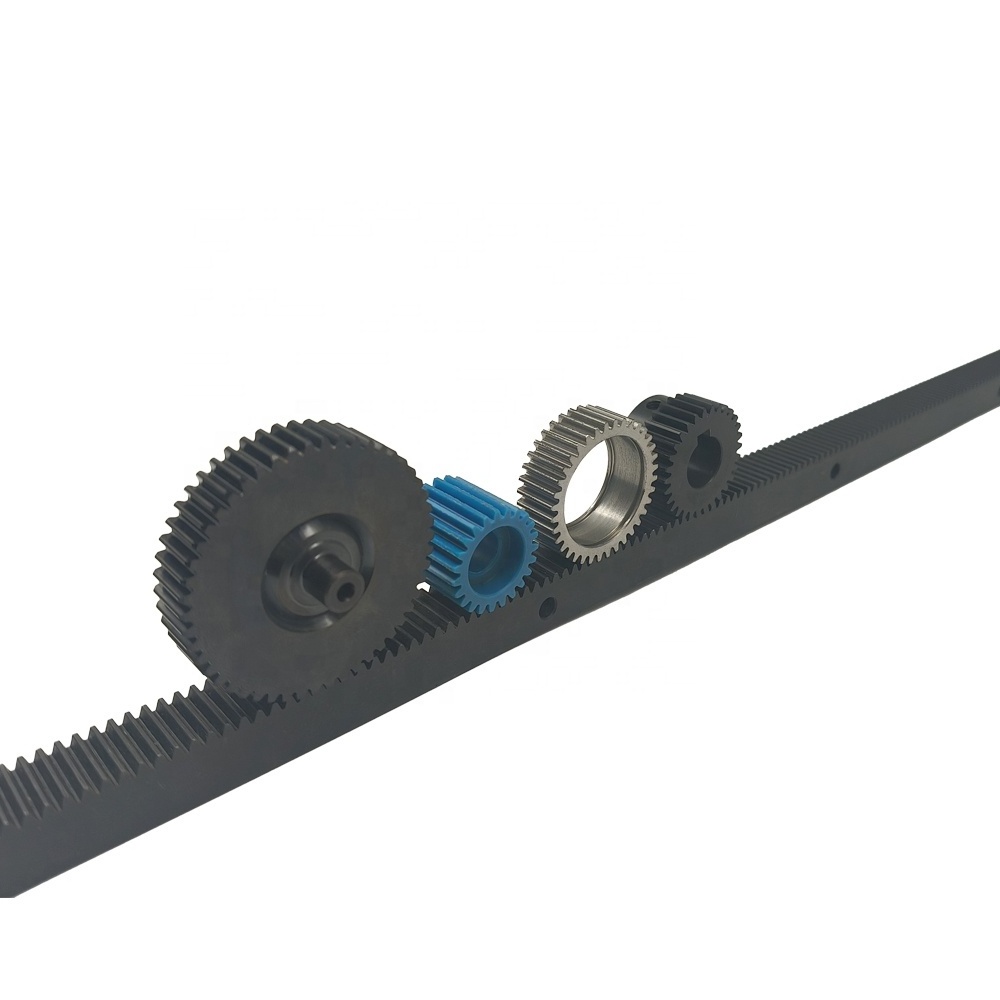

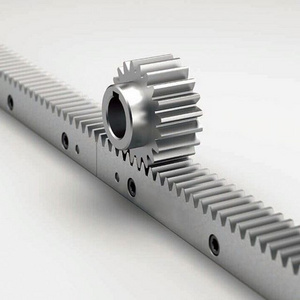

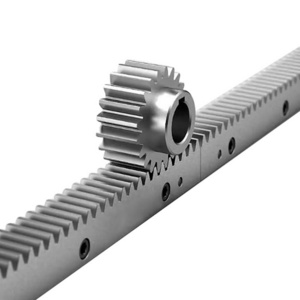

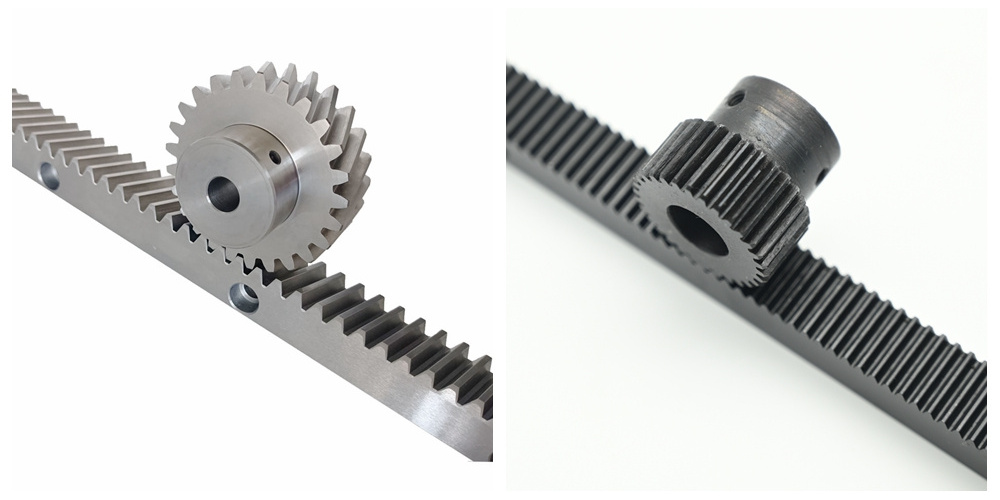

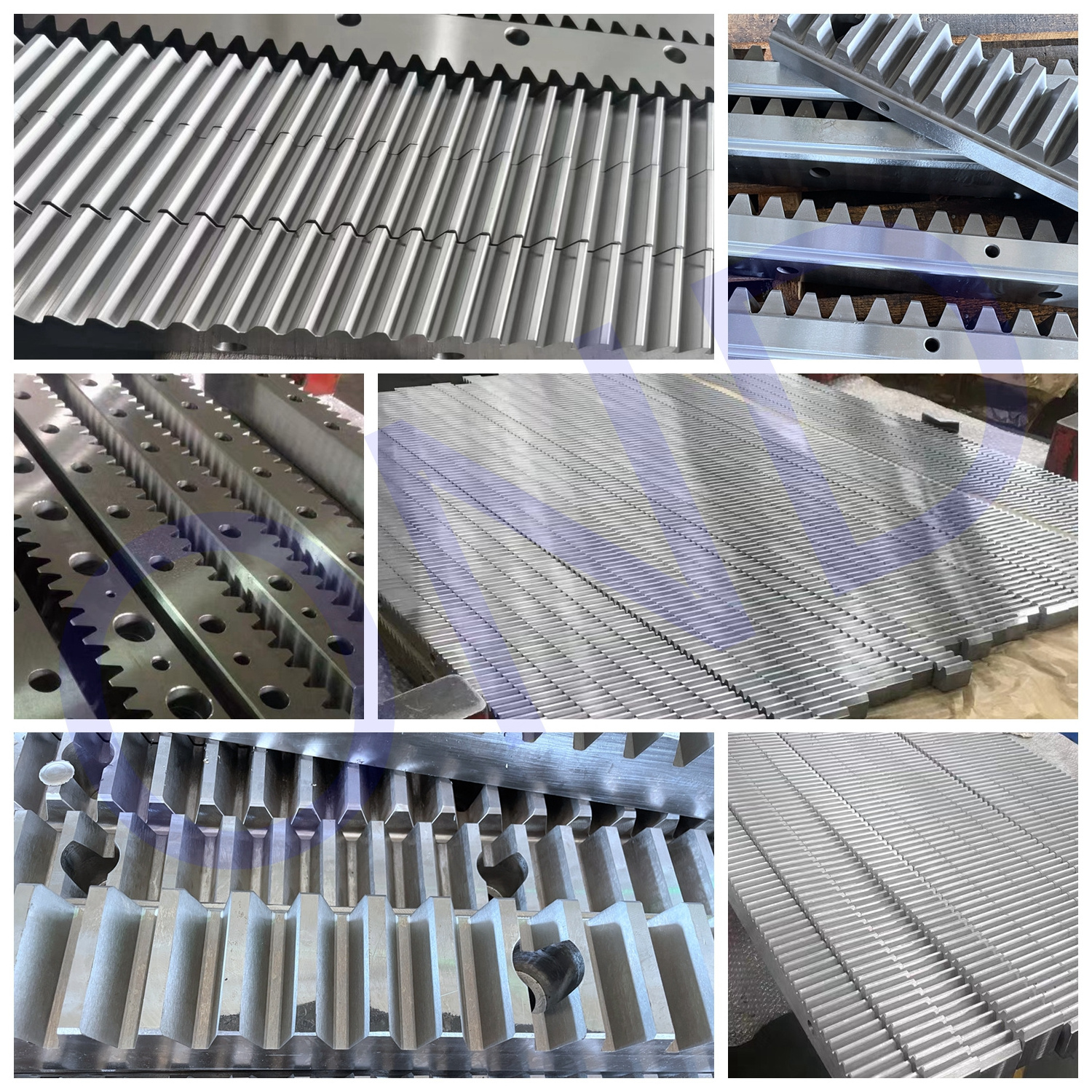

Product Description

|

Product Type

|

Helical teeth gear rack/ Straight teeth gear rack

|

|

Model Number

|

M1 M1.25 M1.5 M2 M2.5 M3 M4 M5 M6 M8 M10 M12

|

|

Length

|

500mm, 1000mm, 2000mm, custom length

|

|

Material

|

C45, 42CrMo, SS304, SS316, nylon, POM

|

|

Helix Angle

|

Standard 19°31'42'' or customized angle

|

|

Precision

|

DIN5 DIN6 DIN7 DIN8 DIN9 DIN10

|

|

Pressure Angle

|

14.5 / 15 / 20 degree

|

|

Finish

|

Black oxide, galvanized, teeth hardened

|

|

Application

|

Automation Machine, CNC Machine, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction works

|

|

Delivery Time

|

Stock size 2-5 days; customized size 10-30 days

|

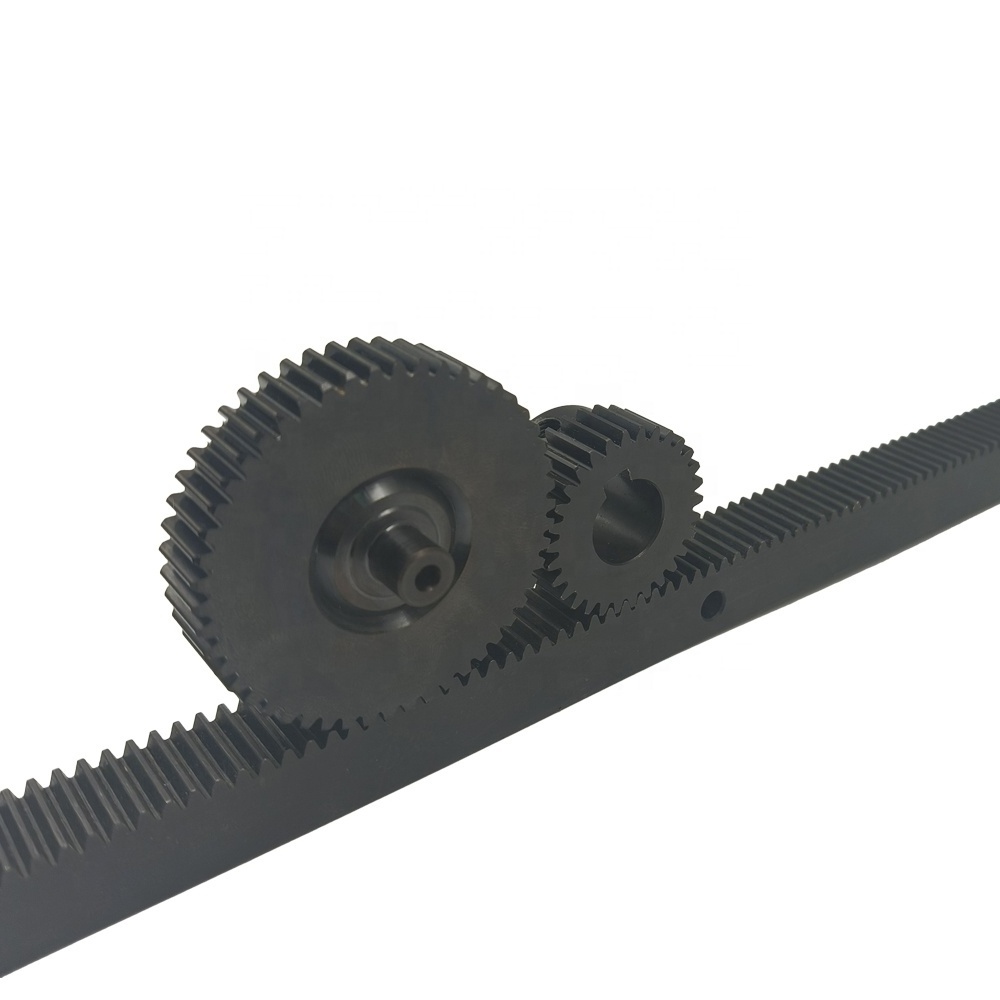

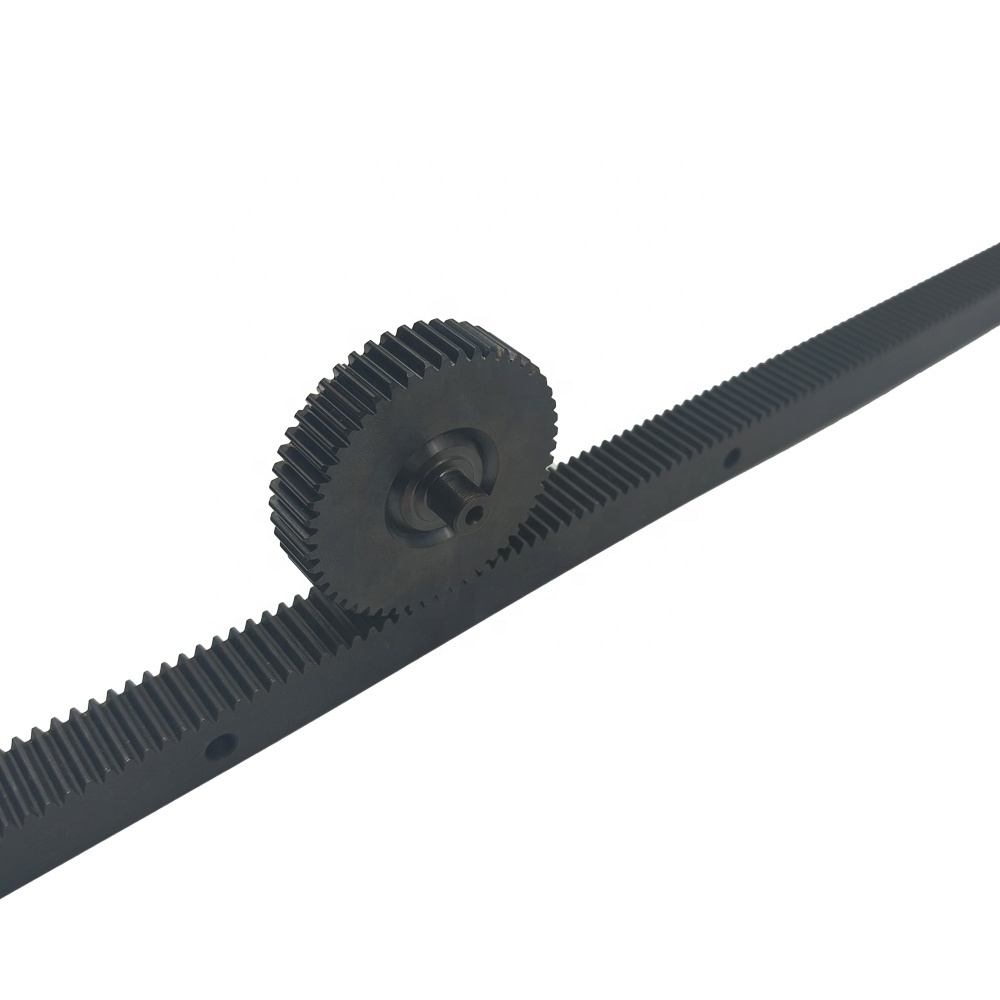

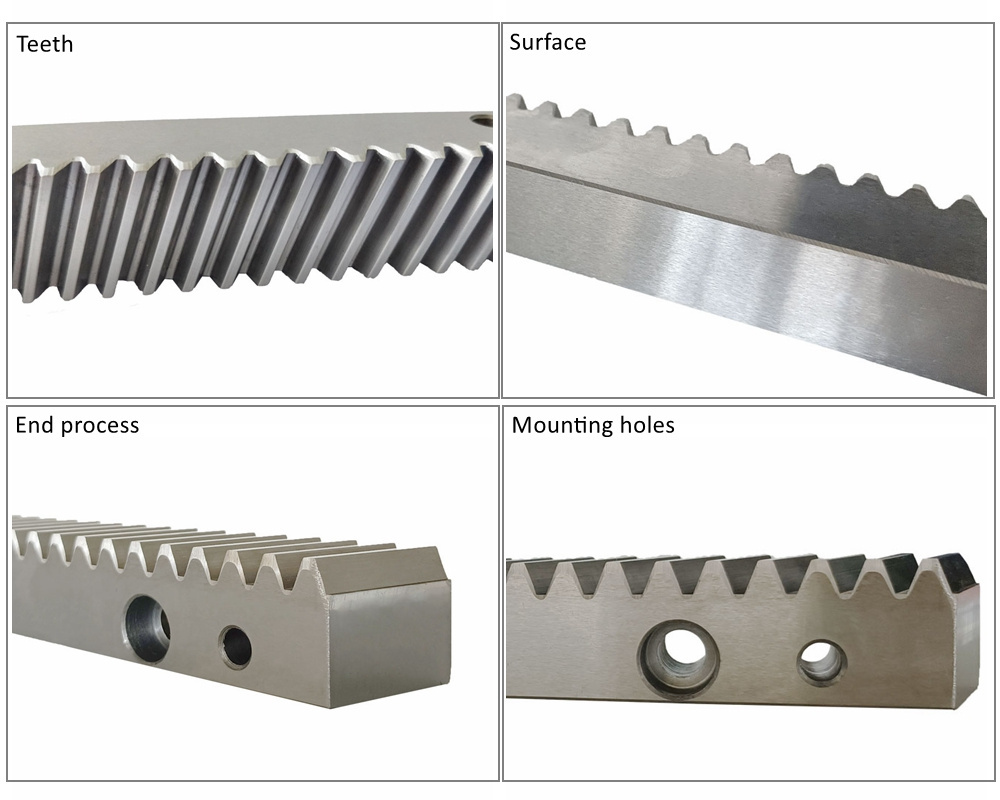

Product Display

Specification

Instruction of Rack Assembly

To assemble connected racks more smoothly, 2 ends of a standard rack would add half tooth which is convenient for next half tooth of next rack to be connected to a complete tooth. The following drawing shows how 2 racks connect and tooth gauge can control pitch position accurately.

With regards to connection of helical racks, it can be connected accurately by opposite tooth gauge.

1. When connecting racks, we recommend lock bores on the sides of rack first, and lock bores by the sequence of the foundation. With assembling the tooth gauge, pitch position of racks can be assembled accurately and completely.

2. Last, lock the position pins on 2 sides of rack; the assembly is completed.

Advantages of rack and pinion transmission

(1) Large transmission power

(2) Long life, stable operation and high reliability

(3) It can ensure a constant transmission ratio and can transmit motion between two shafts at any included angle

mainly used in various mechanical transmission systems, like

Automation Machine, CNC Machine, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction works and so on.

Packing & Delivery

We will pack the goods carefully

before shipping, make sure the goods arrive in good condition.

For small quantity, usually packaged with carton box, delivered by air.

For large quantity, usually packaged with wooden box, delivered by sea.

We also accept custom packing, please contact if you have special require for the packing.

Hot Searches