- Product Details

- {{item.text}}

Quick Details

-

Type:

-

PDC Bearings

-

Material:

-

diamond + tungsten carbide

-

Use:

-

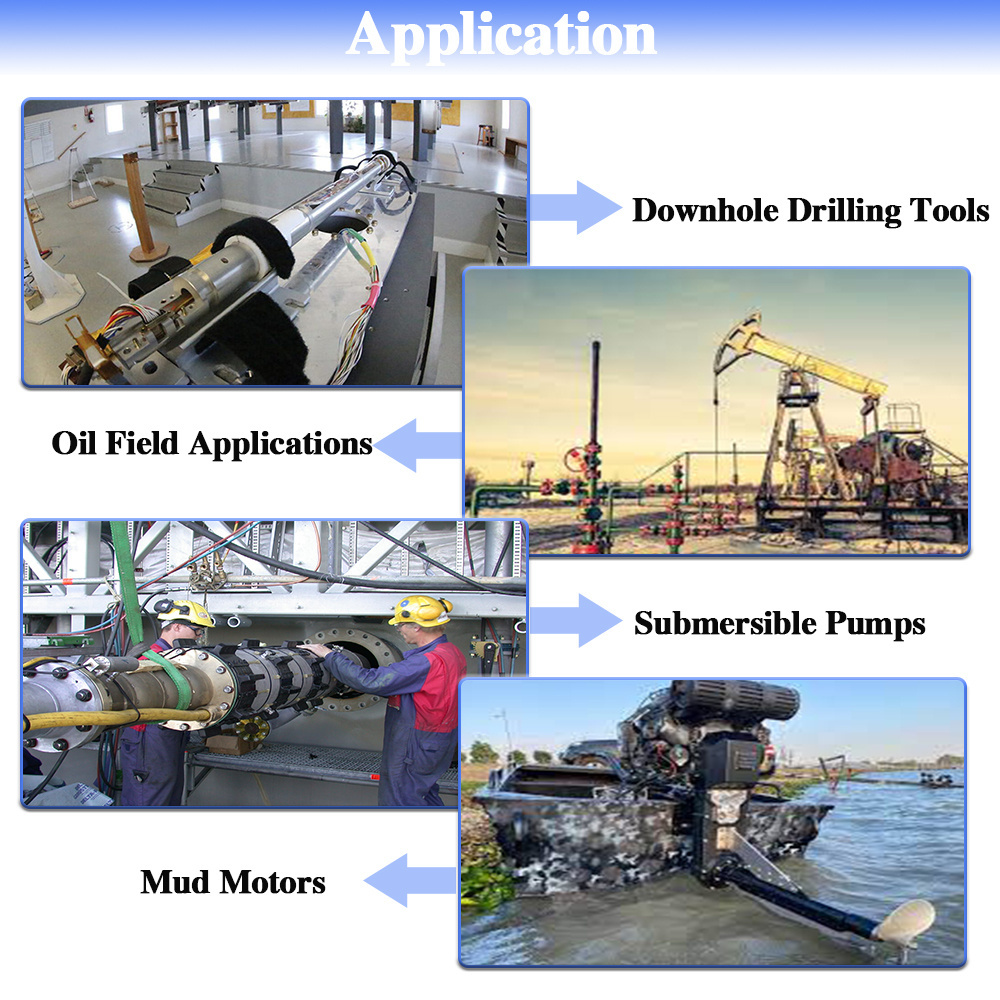

Oil Field Applications

-

Product name:

-

PCD Bearings

-

Size:

-

1"-10"

-

Tensile Strength:

-

≥200 MPa

-

Parallel:

-

≤0.02 mm

-

Flatness:

-

≤0.01 mm

-

Speed:

-

100 to 6000 r/min minutes

-

Feature:

-

Wear resistanceimpact PDC composite cutter

-

Application:

-

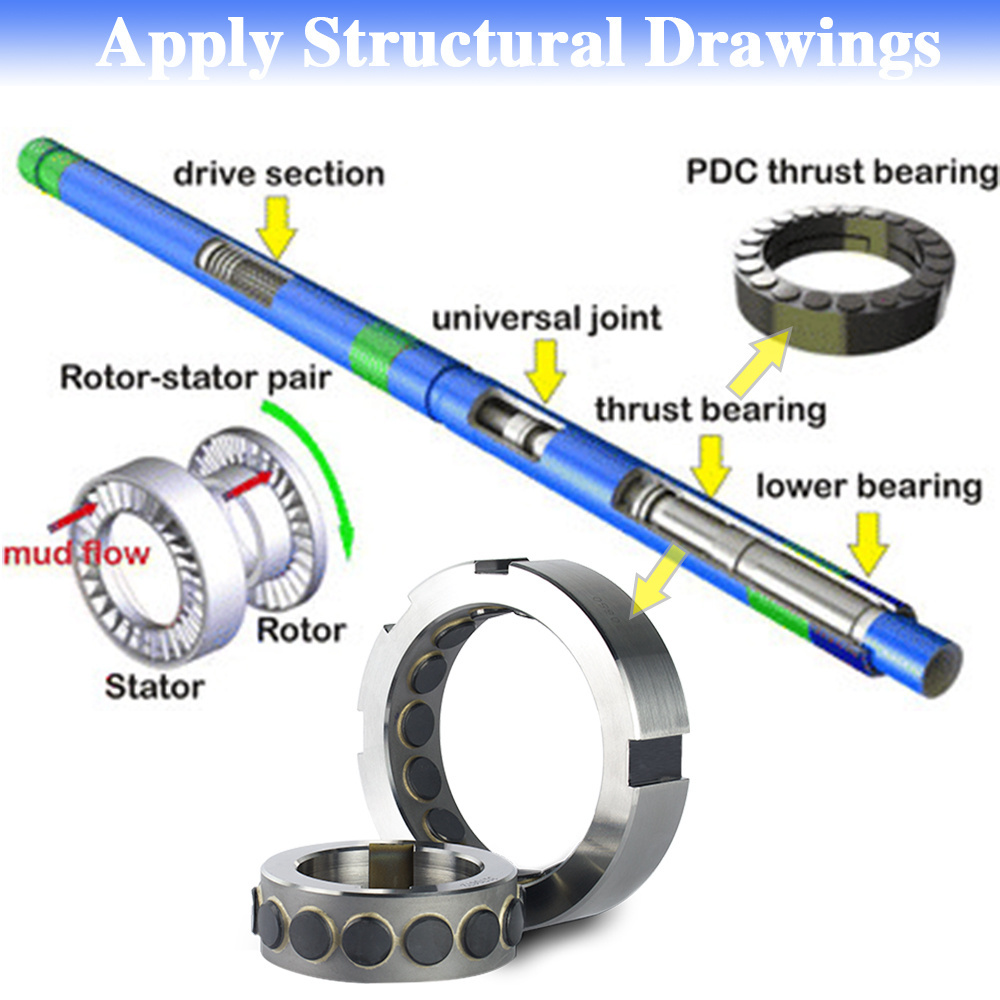

Turbo Drills,Mud Motors,Downhole Drilling Tools

-

Packing:

-

Standared Package

-

Usage:

-

Oil Field Applications

Quick Details

-

Weight (KG):

-

2

-

Place of Origin:

-

China

-

Brand Name:

-

RZ

-

Type:

-

PDC Bearings

-

Material:

-

diamond + tungsten carbide

-

Use:

-

Oil Field Applications

-

Product name:

-

PCD Bearings

-

Size:

-

1"-10"

-

Tensile Strength:

-

≥200 MPa

-

Parallel:

-

≤0.02 mm

-

Flatness:

-

≤0.01 mm

-

Speed:

-

100 to 6000 r/min minutes

-

Feature:

-

Wear resistanceimpact PDC composite cutter

-

Application:

-

Turbo Drills,Mud Motors,Downhole Drilling Tools

-

Packing:

-

Standared Package

-

Usage:

-

Oil Field Applications

Related Products

Products Description

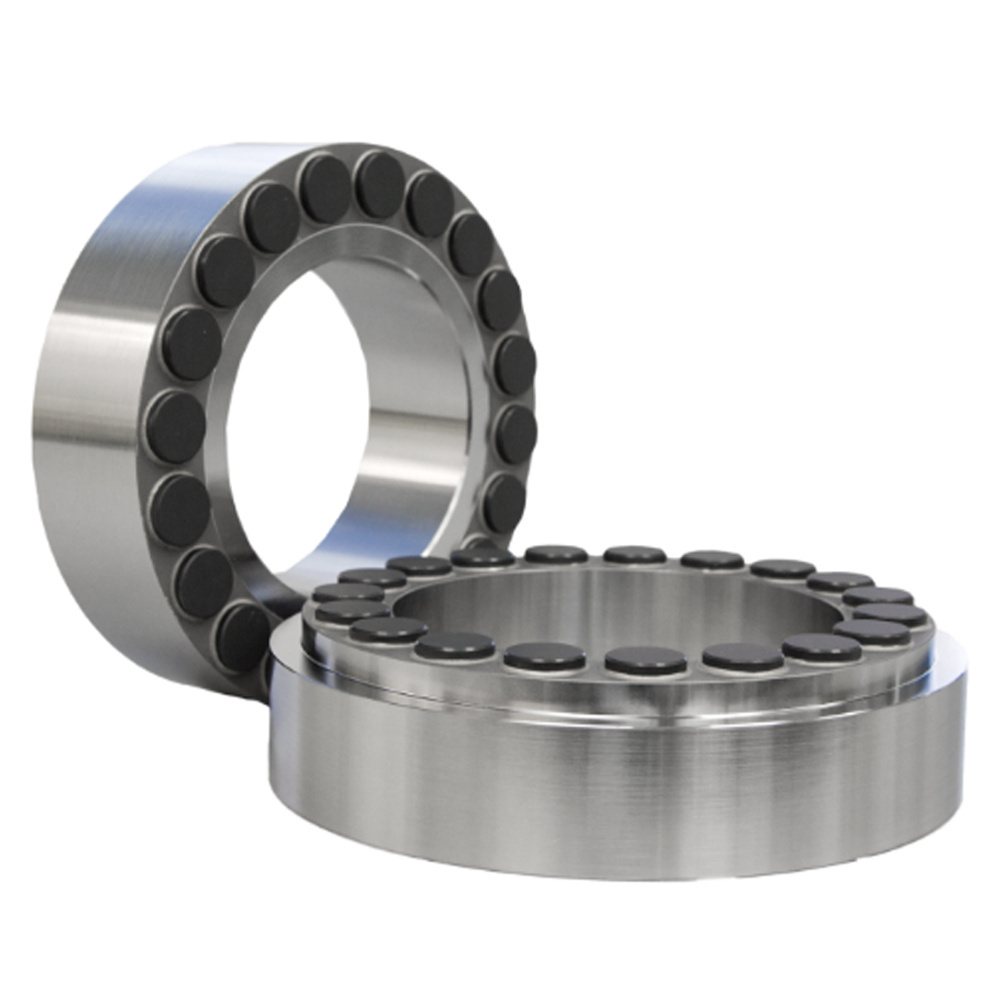

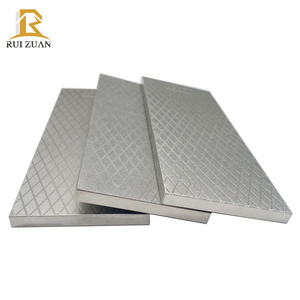

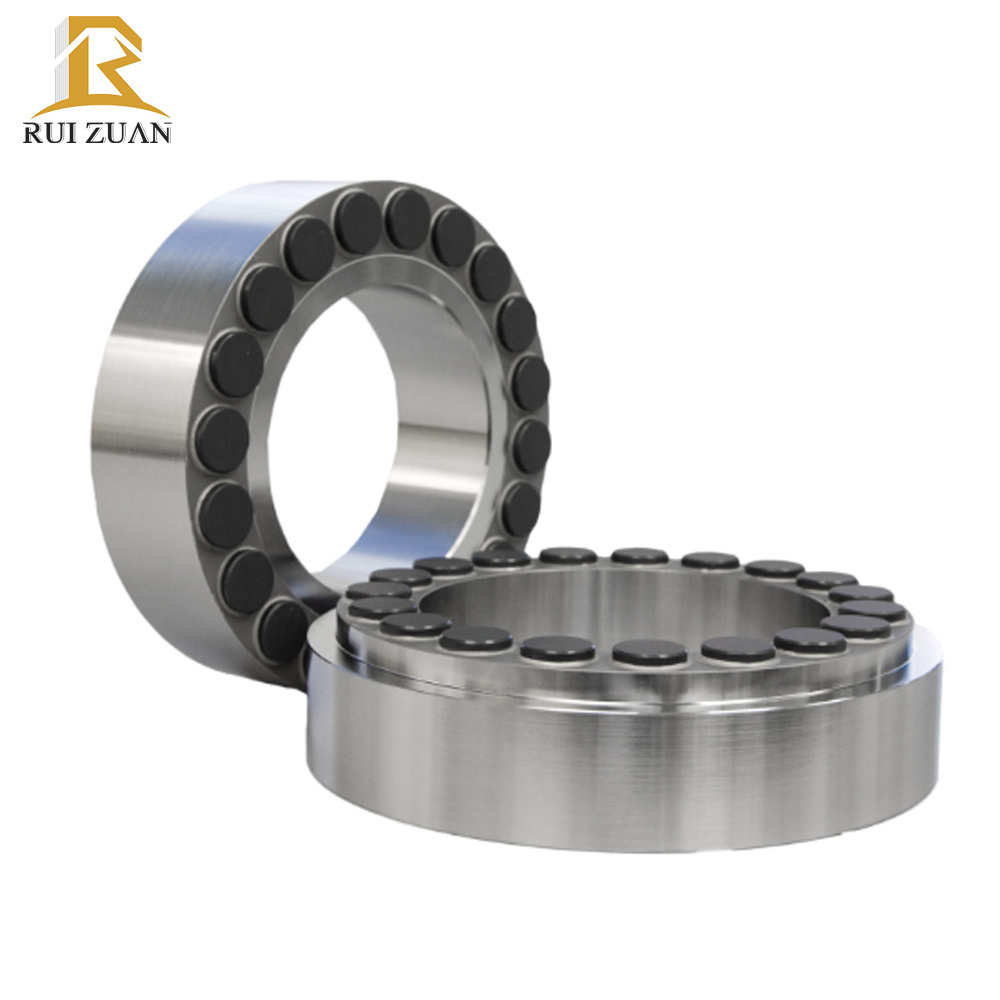

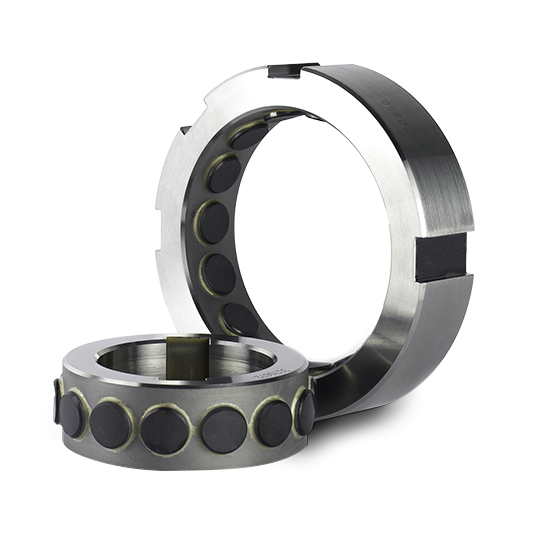

Polycrystalline Diamond (PCD) thrust bearings are comprised of a series of PCD inserts assembled (usually by brazing) in carrier rings. A typical PCD thrust bearing set includes a rotating and stationary bearing ring. These two rings oppose each other with the planar PCD surface of one ring in direct contact with the PCD surface of the mating ring.

|

Model

|

parent casing specifications

|

|

|

OD

|

Drift

|

||

|

|

OD (mm)

|

Wall thickness(mm)

|

ID(mm)

|

mm

|

mm

|

||

|

PDC bearing 2 7/8

|

2 7/8"

|

customized

|

customized

|

customized

|

|

||

|

PDC bearing 2 1/8"

|

2 1/8"

|

customized

|

customized

|

customized

|

|

||

|

PDC bearing 65

|

65

|

customized

|

45

|

65

|

|

||

|

PDC bearing 5.150"

|

5.150"

|

customized

|

customized

|

customized

|

|

||

|

PDC bearing 5.145

|

5.145"

|

customized

|

5.145"

|

5.145"

|

|

||

|

PDC bearing 178×127

|

178

|

11.51

|

154.8

|

146

|

100-124

|

||

|

PDC bearing 178×127

|

178

|

10.36

|

157.1

|

150

|

100-124

|

||

|

PDC bearing 178×140

|

178

|

9.19

|

159.4

|

150

|

100-124

|

||

|

PDC bearing 178×140

|

178

|

8.05

|

161.7

|

150

|

100-124

|

||

|

PDC bearing 245×140

|

245

|

13.84

|

216.8

|

200

|

124-177

|

||

|

PDC bearing 245×141

|

245

|

11.99

|

220.5

|

200

|

124-177

|

||

|

PDC bearing 245×141

|

245

|

11.05

|

222.4

|

200

|

124-177

|

||

|

PDC bearing 245×178

|

245

|

10.03

|

224.4

|

210

|

124-177

|

||

|

PDC bearing 245×178

|

245

|

8.94

|

226.6

|

210

|

124-177

|

||

|

PDC bearing 245×194

|

245

|

7.92

|

228.6

|

210

|

124-177

|

||

Our PDC Bearing advatages are as the following:

1) Highly resistant to abrasion, erosion, corrosion, and mechanical failure.

2) Extremely resistant to chipping,and flaking which are inherent problems in cladding or welded overlay processes.

3) High heat conductivity eliminates thermal cracking.

4) Proprietary design eliminates catastrophic downhole radial bearing failure.

5) Carbide tile and matrix design ensures extended life compared to cladding or welded overlay designs.

6) Inner and outer components can be reconditioned.

7) The hardness of body surface can reach 30-37 HRC.

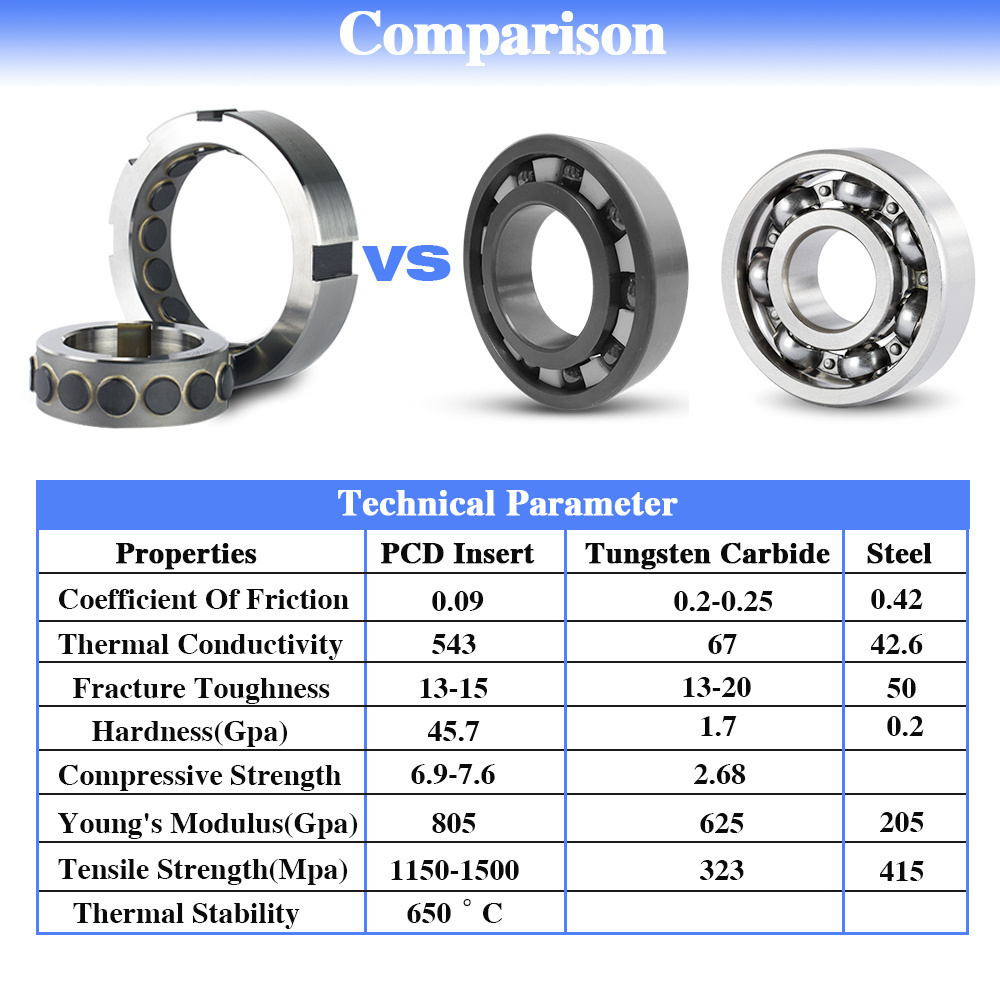

PDC Thrust Bearing is widely used in turbo drills,mud motors and other oil field applications. We have two different types includes PDC radial bearing and PDC thrust bearing.Compared with tungsten carbide bearing,The PDC bearing has longer working life,its life is 4-10 times longer than tungsten carbide bearing, meanwhile it can also bear the increased load capacity.

As Anti-Friction Bearing For Downhole Motor, Which Is Widely Used In Turbo Drills, Mud Motors, Electric Submersible Pumps And Many Other Oil Field Applications.

Why Choose Us

Hot Searches