- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1790*2940*2450-1790*3240*2600

-

Power (kW):

-

30

-

Weight (KG):

-

3000 KG

-

Color:

-

custom made

-

Material:

-

custom made

-

size:

-

custom made

-

Total Discharge Amount(G/Min):

-

250-30000

-

Pouring Head Stirring Speed(R/Min):

-

3000-5000

-

Weight(Kg):

-

Weight(Kg)

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

zecheng

-

Machine Type:

-

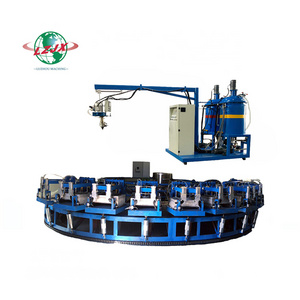

Wheel Casting Polyurethane Machine

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1790*2940*2450-1790*3240*2600

-

Power (kW):

-

30

-

Weight (KG):

-

3000 KG

-

Color:

-

custom made

-

Material:

-

custom made

-

size:

-

custom made

-

Total Discharge Amount(G/Min):

-

250-30000

-

Pouring Head Stirring Speed(R/Min):

-

3000-5000

-

Weight(Kg):

-

Weight(Kg)

Product Description

Features

1.Independent PLC control system in the branch temperature controller of each group,with special electri cheating system, oven,

piping and valves which can be adjusted separately; multi-point temperature control device is used to ensure that the raw

materialto maintain a constant temperature throughout the cycle process; temperature error≤+2C.2.The mixing device is equipped

with static pressure balance device (patented technology), which removes flow error and improve measuring accuracy, meanwhile the

stability is better; variable cross-section straight tooth conical mixing head is used to ensure no visible bubbles in products.

3.Equipped with the color paste control system and the color paste directly goes into the mixing device;different colors can be

switched at any time; the mixing is uniform and the metering is accurate.4.Adopt the imported PCL controller to monitor the entire

device control system; it will automatically make5.judgment of abnormity, diagnosis and alarm, abnormal factors display, PLC

module control, casting, automatic cleaning and air impact; stable performance and strong operability.

piping and valves which can be adjusted separately; multi-point temperature control device is used to ensure that the raw

materialto maintain a constant temperature throughout the cycle process; temperature error≤+2C.2.The mixing device is equipped

with static pressure balance device (patented technology), which removes flow error and improve measuring accuracy, meanwhile the

stability is better; variable cross-section straight tooth conical mixing head is used to ensure no visible bubbles in products.

3.Equipped with the color paste control system and the color paste directly goes into the mixing device;different colors can be

switched at any time; the mixing is uniform and the metering is accurate.4.Adopt the imported PCL controller to monitor the entire

device control system; it will automatically make5.judgment of abnormity, diagnosis and alarm, abnormal factors display, PLC

module control, casting, automatic cleaning and air impact; stable performance and strong operability.

|

Component name

|

Mixing ratio

|

Temperature ( ℃ )

|

Viscosity (CPS)

|

|

A (Prepolymer)

|

100

|

Room temperature~110

|

100~3000

|

|

B(MDI Semi- prepolymer)

|

60-150

|

Room temperature~110

|

100~3000

|

|

C(14 Butanediol or BDO)

|

4~15

|

Room temperature~130

|

100~3000

|

|

Catalyst

|

0.3~3

|

Room temperature

|

50~2000

|

|

Color paste

|

0.5~3

|

Room temperature

|

50~2000

|

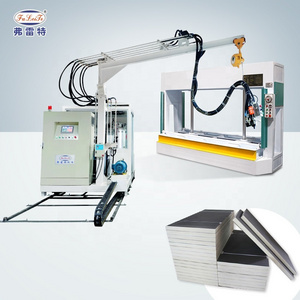

Application

Applicable to the manufacture of casting polyurethane elastomer products whose cross-linking agent is MOCA or BDO etc, such as all

kinds of rubber roller,high load solid core wheel, mine sleve plate, hydraulic seal ring, photovoltaic guide pulley and other

highly wear-resistant materials in metallurgy, printing and dyeing,textile, mining and paper industry.

kinds of rubber roller,high load solid core wheel, mine sleve plate, hydraulic seal ring, photovoltaic guide pulley and other

highly wear-resistant materials in metallurgy, printing and dyeing,textile, mining and paper industry.

|

Model

|

CPU20J-1

|

CPU20J-2

|

CPU20J-3

|

CPU20J-5

|

CPU20J-6

|

CPU20J-7

|

|

Total Flow Rate (g/min)

|

250-800

|

1000-3500

|

2000-5000

|

5000-15000

|

8000-20000

|

10000-30000

|

|

A Tank capacity (L)

|

160

|

160

|

250

|

400

|

400

|

400

|

|

B Tank capacity (L)

|

30

|

30

|

80

|

80

|

80

|

80

|

|

Pouring head stirring speed(r/min)

|

3000-5000

|

3000-5000

|

3000-5000

|

3000-5000

|

3000-5000

|

3000-5000

|

|

Height from the ground(mm)

|

1200

|

1200

|

1200

|

1300

|

1300

|

1300

|

|

Total power(kw)

|

19

|

19

|

20

|

22

|

23

|

25

|

Products Recommended

Exhibit show

Hot Searches