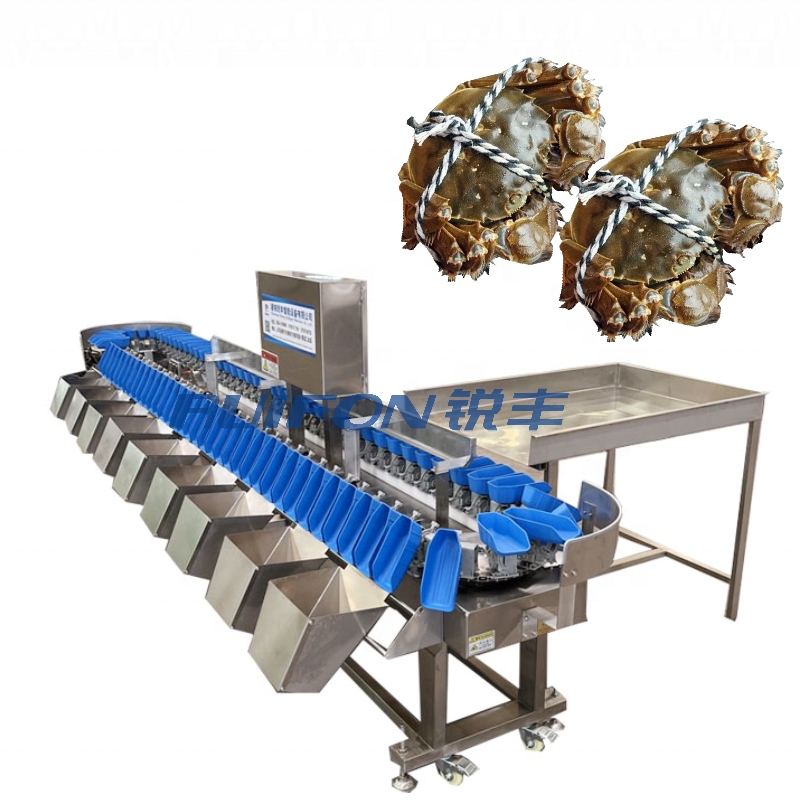

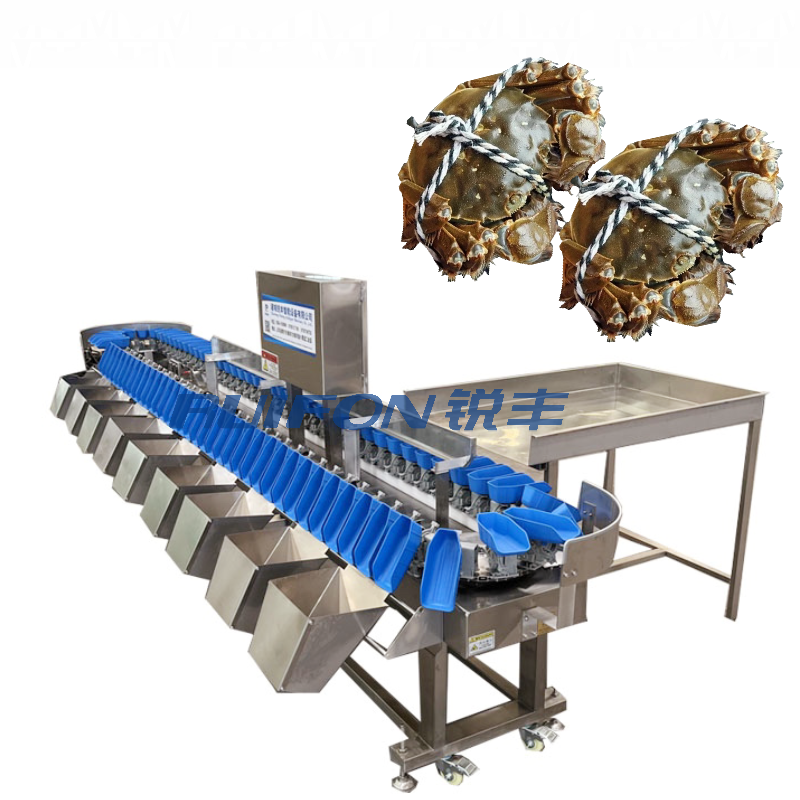

1. Front-end conveying mechanism: conveying the measured object to the weighing mechanism, on the one hand, giving the object an initial speed, so that it can reach stability faster after entering the weighing mechanism; On the other hand, it can isolate and dampen the front-end materials and ensure the measurement accuracy. 2. Intermediate weighing mechanism: This part is the most critical part of the whole mechanical system, and its structural design and installation accuracy directly affect the measurement accuracy of the system. It consists of conveying motor, photoelectric monitoring part and weighing sensor. Complete the dynamic weighing of the object. 3. Back-end sorting mechanism: This part is the action part of sorting, which consists of conveying part, pneumatic valve, hopper, etc. Complete the rejection and sorting of unqualified parts of objects. The rejection mode can be set as blowing, pushing, shifting, dropping, etc.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V, 220V

-

Power:

-

7.5KW, 0.75

-

Weight:

-

500 KG, 200 KG

-

Dimension(L*W*H):

-

4500*1000*1500

-

Year:

-

2022

-

Product name:

-

Weight grading machine

-

Brand:

-

Kaierit

-

Usage:

-

Food Processing Industries

-

Suitable for:

-

Fish Grading Equipment

-

Keywords:

-

Fish Processing Products

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Kaierit

-

Type:

-

Sorting Machine, Weight grading machine

-

Voltage:

-

220V, 220V

-

Power:

-

7.5KW, 0.75

-

Weight:

-

500 KG, 200 KG

-

Dimension(L*W*H):

-

4500*1000*1500

-

Year:

-

2022

-

Product name:

-

Weight grading machine

-

Brand:

-

Kaierit

-

Usage:

-

Food Processing Industries

-

Suitable for:

-

Fish Grading Equipment

-

Keywords:

-

Fish Processing Products

Product Presentation

Online check weight scale, also known as weight detection machine, weight sorting machine, automatic check weight scale, weight sorting machine, it is in the dynamic situation of the production line to achieve high-speed, high-precision weight detection and automatic sorting of light or heavy products equipment, thus greatly improving product quality and optimize the production process, so as to control costs, eliminate waste, increase profits. It can be used to inspect all products on the production line and comprehensively display production data such as production quantity, batch tracking, total weight, effective weight, and discard weight.

Product Photography

Product Duitable For

Product Details

Product feature

Product Parameter

|

Name

|

Sorting accuracy

|

Weighing error

|

Weighing speed

|

|

Weight separator

|

2g

|

±0.2g

|

180-320Every minute

|

|

Material

|

Voltage

|

Machine size

|

|

|

SUS304

|

220

|

4500*1000*1500mm

|

|

Product delivery

Packing & Transport

Hot Searches