Name:

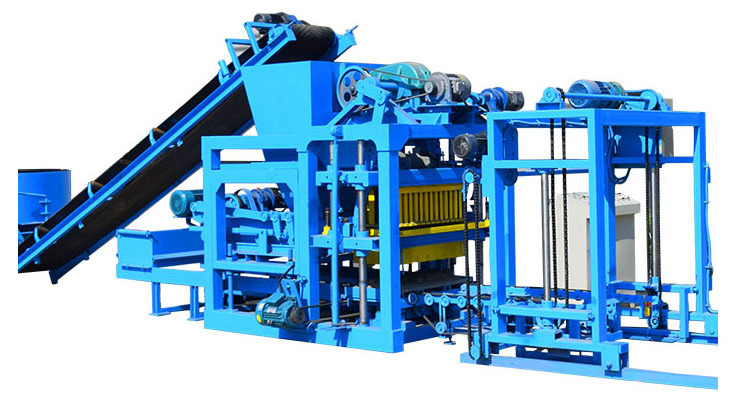

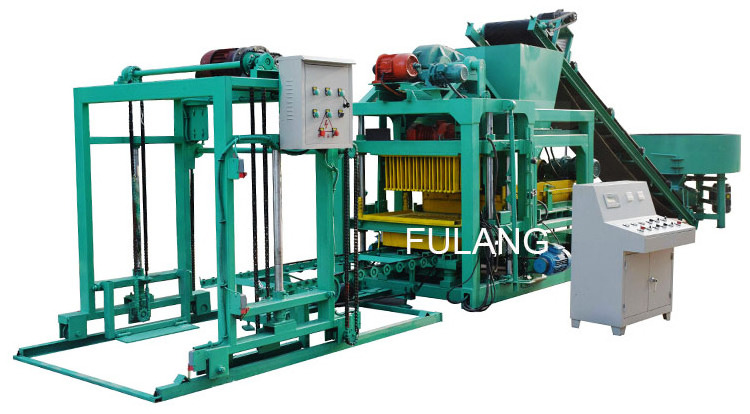

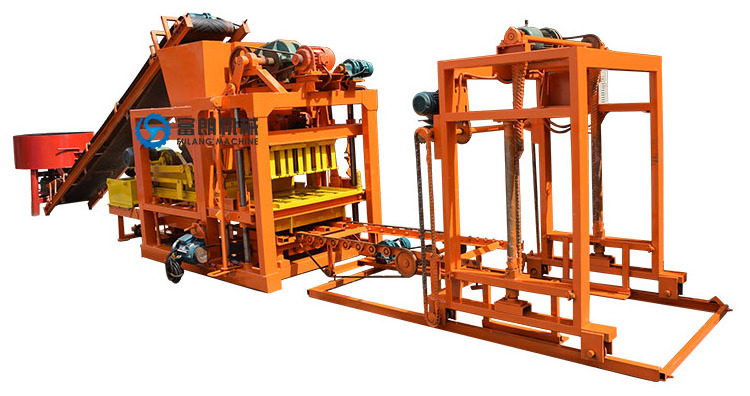

QTF4-25A host machine

Brand:

FULANG

Original:

China

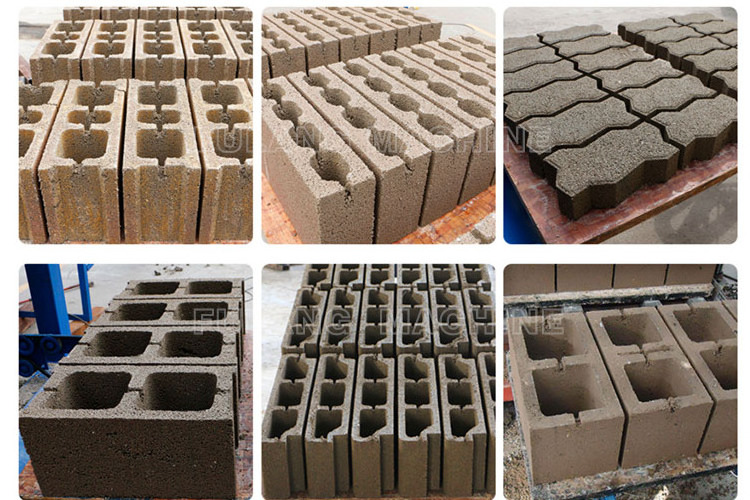

Domestic famous motor, use national standard Q345 steel and good welding,can make kinds of hollow and solid brick just by changing mould.

- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fulang

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1900*1900*1860mm

-

pressure:

-

1500KN

-

Weight:

-

3 ton

-

Workshop area:

-

100m2

-

Cylinder:

-

250mm

-

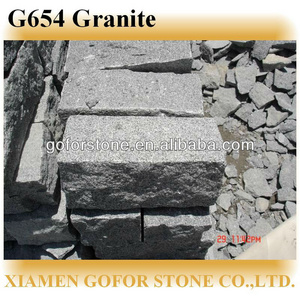

Block type:

-

All kinds of special shape, large size,high intensity stone pavers

-

Color:

-

according to your needs

-

Pallet size:

-

850*550*20mm

-

Molding cycle:

-

10~15s

-

Certification:

-

CE,ISO

Quick Details

-

Type:

-

Paving Block Making Machine

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

3000~5000pcs/day

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fulang

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1900*1900*1860mm

-

pressure:

-

1500KN

-

Weight:

-

3 ton

-

Workshop area:

-

100m2

-

Cylinder:

-

250mm

-

Block type:

-

All kinds of special shape, large size,high intensity stone pavers

-

Color:

-

according to your needs

-

Pallet size:

-

850*550*20mm

-

Molding cycle:

-

10~15s

-

Certification:

-

CE,ISO

1.Host machine:

We use national standard Q345 steel and good welding.

2.Motors:

using national famous brand motor,can be customerized with Siemens and ABB brand.Voltage can be made according to your local voltage

3.Mould:

Adopt line cutting technology and carburizing technology which make the mould with high precision and longer service life.

4.Hydraulic station:

with hydraulic station can make the produced bricks with high density and good quality.

5.Production line: with JQ500 concrete mixer,conveyor belt,pallet feeder and brick stacker make this machine woked with high efficiency.

6.

After service:

Machine shipping with detail operation manual and maintainance tips.Make the customer use the machine more convenient.

|

SPECIFICATIONS FOR QTF4-25A CONCRETE BRICK MAKING MACHINE

|

|

|

|

|||

|

Dimension of host machine

|

3700x2100x2300mm

|

Host machine power

|

16.35KW

|

|||

|

Mould period

|

20S

|

Vibration force

|

35.5KN

|

|||

|

Size of pallet

|

850x550x20mm

|

Workshop

|

100㎡

|

|||

|

Weight of host machine

|

3T

|

Mixer model

|

JQ500

|

|||

Host machine

Conveyor belt

Name:

6 meters conveyor belt

Brand:

FULANG

Original: China

Domestic famous motor, strong and steady driving force, low power consumption, steady convy speed,make the whole line more efficiency.

Pallet feeder

Name: Auto pallet feeder

Brand: FULANG

Original: China

Domestic famous motor, strong driving force, low power consumption, high economic benefits with this QTF4-25A concrete brick making machine

Mould

Name:

Brick mould

Brand:

FULANG

Original:China

Adopt line cutting technology and carburizing technology which make the mould with high precision and longer service life.

We are the supplier and manufacturer ,specialize in block/brick machinery many years .We have rich experience and high service quality including pre-sale,in-sale and after-sale service for more than 20 years.

Our main products are Automatic Burnfree brick making machine , aerated concrete block production line,use Germany technology,German Simens motor,PLC systerm.The aerated concrete wall panel production line, autoclaved lime sand brick production line, autoclave etc.A and second-class pressure vessel, aerated concrete blocks, sand-lime brick, panel products, Oxygenated diesel, dimethyl ether , plant asphalt nine series,more than 60 varieties.

If you are interested with our products, please don't hesitate to contact us. You can tell me the following questions, Then I can send you accurate quotation soon, including additional discount!

1. Which machine do you need? like brick making machine,mixer,batching plant,or the whole line, etc.

2. what is your raw material plan to process? like clay,sand,cement,concrete,slag, etc.

3. The capacity you need. Like 1000 pieces per hour or 2000 pieces per day.

4. Your contact information. Both Email and phone number are essential, we can contact you easier.