We can provide the turn-key project.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

tongsan

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

25M*2.5M*3.5M

-

Weight:

-

20 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

pp pe pvc,wood powder

-

Processing Type:

-

WPC extrusion

-

Final product:

-

WPC decking,WPC flooring,WPC profile,WPC wall cladding

-

Motor:

-

SIEMENS Brand

-

Inverter brand:

-

ABB DELTA

-

Feature:

-

High Production Efficiency

-

Marketing Type:

-

Hot Product 2021

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

22:1

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

tongsan

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

25M*2.5M*3.5M

-

Weight:

-

20 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

pp pe pvc,wood powder

-

Processing Type:

-

WPC extrusion

-

Final product:

-

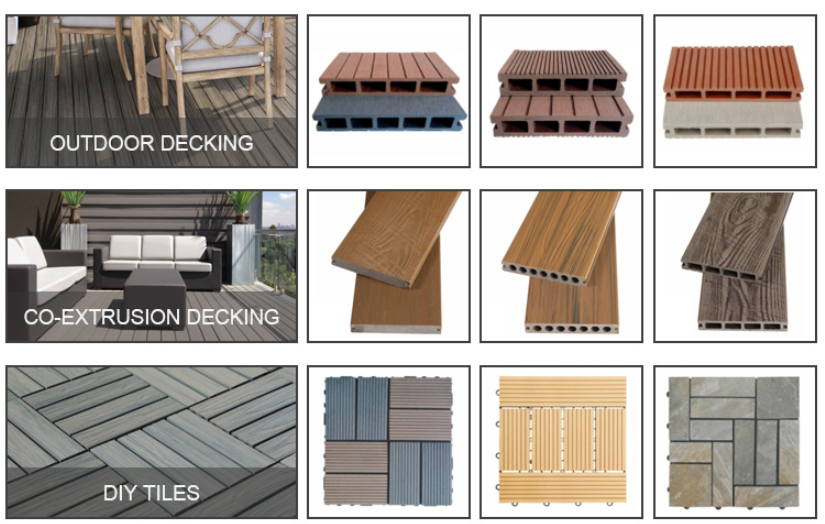

WPC decking,WPC flooring,WPC profile,WPC wall cladding

-

Motor:

-

SIEMENS Brand

-

Inverter brand:

-

ABB DELTA

-

Feature:

-

High Production Efficiency

-

Marketing Type:

-

Hot Product 2021

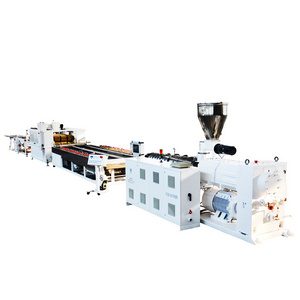

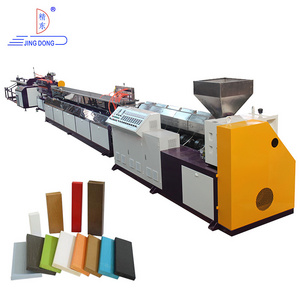

Product Description

Combining advanced Canadian technology and the domestic practical situation, our company developed the SJMS series WPC production machine lin.WPC profile extrusion machine is adopted specially designed screw, barrel, mould and unique WPC craft and formula initiated by our company. The extruder can match with the auxiliary machines and moulds perfectly. The whole production line is of automatic control from the loading to the final discharging. The machines can also be manually adjusted separately. With the advantages of good plastication, low energy-consumption, high output, excellent performance, long endurance, etc. It can be equipped with relative auxiliary equipment, such as vacuum calibration platform, haul-off machine, cutting machine and material stacker. It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes, outdoor landscapes, pallets, etc.

Material:Recycled PP PE PVC and plant tibre(wood powder/chaff/straw etc)

Production proecss:

PP PE Wood Plastic Composite : milling→mixing→granulating→extruding→final product surface treatment

PVC Wood Plastic Composite : milling→mixing→extruding→final product surface treatment

The features of WPC profile making machine

1)This technology is suitable to produce WPC products at high value with variety of plastic and nature fiber,and the material is 90% of waste plastic and waste natural fiber.

2)With scientific and reasonable technology,the machine has high efficiency and runs stably

3)The parallel twin screw extruder is used to mix the wood and plastic,and get good homogeneous melt.

4)This is one step WPC extrusion technology,which saves energy

5)This production line can produce wpc products of different specifications only to change mold.

6)Imported PLC automatic control.

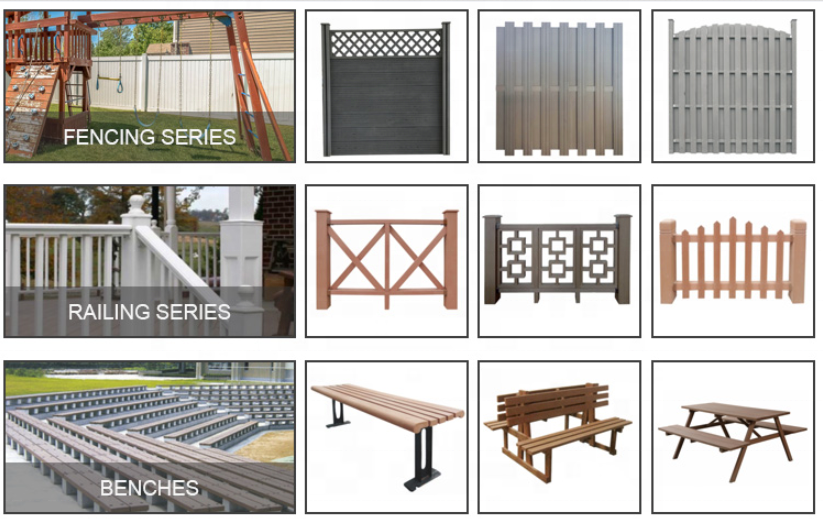

The final product application: floor,decking,pallet,outdoor landscape architecture,fence,post,

wall panel,door and window profile,etc.

By changing the moulds,the wood plastic compoite machine can produce vairous of profiles.

The mould can be customized by client's requirement

Main technical parameter:

|

Model

|

SJMS 65/132

|

SJMS80/156

|

SJMS 92/188

|

|

Screw diameter

|

65

|

80

|

92

|

|

L/D ratio

|

22(25)

|

22(25)

|

22(25)

|

|

output

|

200-240

|

250-350

|

400-500

|

|

motor power

|

37

|

55

|

110

|

|

heating power

|

4zones,20kw

|

5zones,38kw

|

6zones,54kw

|

Detailed Images

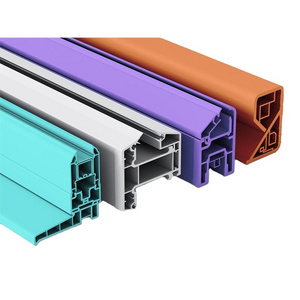

Adding the extra single screw extruder for

co-extrusion,you can get the colorful surface WPC profiles.With the online embossing roller, the WPC profiles can be embossed the

wood pattern,

co-extrusion,you can get the colorful surface WPC profiles.With the online embossing roller, the WPC profiles can be embossed the

wood pattern,

By changing the molds,this WPC machine can produce various of WPC profiles,such as WPC wall cladding panel,WPC clounm,WPC profiles,etc.

We are also the mold manufacturer, the mold can be customized by your request.

We are the professional manufacturer of wood plastic composite WPC profile machine.

We can provide the turn-key project.

Wood Milling Machine for making the wood powder from saw dust,rich husk,plant straw,etc

WPC Granulating Machine for making the WPC granule from wood powder,recycled PP PE,and chemical additives.

We are professional manufacturer since 1997.

Own facotry,Ready made machines in stock.

Now we have ready made machines in the factory.

If you are interested in our WPC machines,please let me know.

LOOKING FORWARD TO YOUR INQUIRY

If you are planning to build factory of making WPC decking/floor/profiles,please contact me at any time.

Hot Searches